How to easily identify the fuel cell stack model parameters from your experimental data

Introduction

Now the adoption of Battery Electric Vehicles (BEVs) is growing steadily, the alternative of energy storage in hydrogen is considered a strong alternative for the future. While hydrogen infrastructure is still limited and probably one of the main barriers to adoption of fuel cells, the technology offers interesting advantages in the race to achieve emission reduction goals. No wonder many Automotive OEM’s and their suppliers increase their efforts on developing Fuel Cell Electric Vehicles (FCEVs).

Being able to assess performance before full vehicles are made is of utmost importance, especially for technologies that are still incubating and where the best practices are not yet found. For fuel cells there are often experimental data available on the performance of the fuel cell itself, but as an engineer working on the full vehicle, it’s incredibly valuable to have a predictive fuel cell model available in the early development stages. Good news, the fuel cell parameter identification tool is ready to help you!

How it works

This article shows how to use the Fuel Cell Parameter Identification Tool application to parameterize your fuel cell electrochemical stack model from experimental data. With a CSV table gathering different cell voltages for different operation conditions, the tool can identify the parameters of the model so that the simulation results correlate with experimental data.

The model

The model used in this example is made of:

- a gas mixture definition section. It sets the properties of the gas mixtures at both cathode and anode sides, the condensation phenomenon and the GDL (Gas Diffusion Layers) gas transport resistive effect.

- a fuel cell stack model with the associated Gas Mixture components. It models the fuel cell reactions at the electrodes, the membrane behavior and the resulting voltage according to the gas mixture boundary conditions. The model can for instance be used to capture the impact of pressures, temperatures, membrane water content and gas mixtures composition.

- a calibration supercomponent. It sets the boundary conditions of the fuel cell model in order to run it under the same operating conditions as the given experiments.

Parameters identification process

The Fuel Cell Parameter Identification Tool launches several simulation in Simcenter Amesim, one after each other, until the identification process converges. The sketch in Simcenter Amesim must first be prepared and adapted to the fuel cell you want to parameterize on experimental data. Then you can launch the application, import experimental data, set the optimization parameters, and launch the identification process.

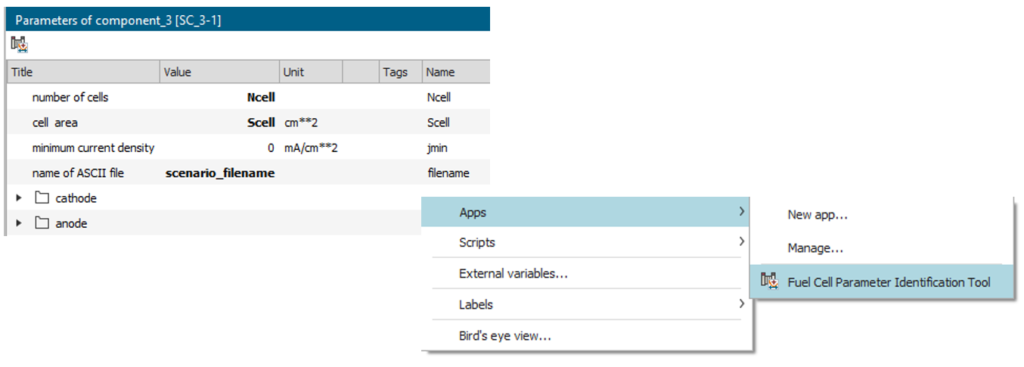

Before launching any parameter identification process on experimental data, you must give the following characteristics of the fuel cell stack you want to model in the global parameter window or in the calibration supercomponent:

- the number of cells and the cell active area,

- the membrane characteristics,

- the channels rough geometry,

- the minimum current density allowed for stoichiometry computation.

The Fuel Cell Parameter Identification Tool is launched by clicking on the app button in the parameter window of the calibration supercomponent. It can also be launched by right-clicking the calibration supercomponent and selecting Fuel Cell Parameter Identification Tool in the Apps sub-menu.

To use this tool, you must follow the following steps:

- Open the data file.

The data must be written in a csv file containing the experimental data with parameters like stack current density [mA/cm2], cell voltage [V], air pressure drop [mbar] and H2 mixture pressure drop [mbar]. - Set the simulation options and optimization settings

- Select parameters to identify

- Run the optimization towards the desired accuracy or the maximum number of iterations you want to evaluate.

- Observe the optimization results

Plots make it possible for the user to compare the fuel cell operating points imported from the data file and the simulation results with the fitted parameters.

Conclusion

This article shows you the identification process of the fuel cell electrochemical stack model parameters from experimental data with the Fuel Cell Parameter Identification Tool. You can use this tool as a virtual test bench to compare simulation results with experimental data. Once parameters are correctly identified, you have the possibility to copy/paste it directly into a system integration sketch and evaluate its performances with the balance of plant components.

This new feature is part of the Simcenter System Simulation 2210 release, read this blog with more exciting new features.