How to accelerate your heavy equipment digital transformation

Catch up on simulation and testing solutions for heavy equipment performance engineering, to support your digital transformation.

As an industry player, you face many challenges, including new regulations, workforce shortages within the industry, and, for some of you, the need to reduce R&D and manufacturing costs to tackle this past year’s market difficulties.

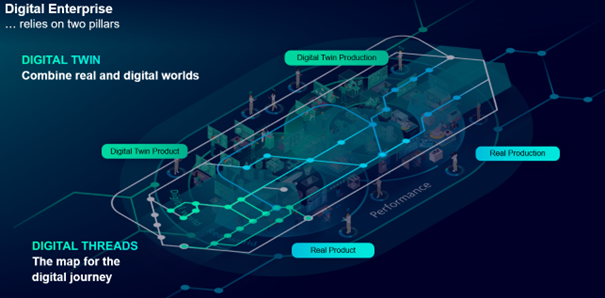

As always, Siemens’ mission is to guide you into your digital transformation with the deployment of our two pillars: the Digital Thread and the Digital Twin. Both pillars rely on the same value proposition: combining virtual representations of the machine or system you are developing with the real machine currently being developed. The same concept applies to the development process, from design and engineering to the manufacturing and maintenance of this machine.

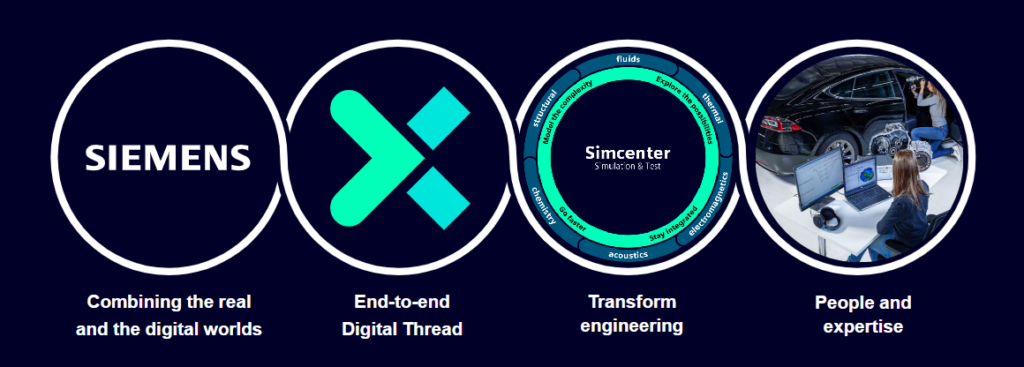

When we focus on the Digital Twin pillars, Siemens collaborates daily with engineering departments that are using our comprehensive simulation and testing solutions: the Simcenter portfolio. To summarize, and make it clearer, Simcenter solutions support the engineering department in four main application domains:

R&D and engineering department’s ‘historical’ objective had been to innovate and create machines that would answer the challenges of the final operators; the reality is more complex. Time to market and program costs are key requirements and, consequently, drivers of efficient engineering and manufacturing workflows.

That is why Siemens has invested tremendous efforts in the past decade to propose interconnection between the simulation domains, between the testing and simulation activities, and the capability to deploy the Digital Twin across the enterprise. The objective is an enhanced collaboration between people throughout the development program.

This investment includes the connection of the Simcenter portfolio with your CAD authoring tool and the Product Lifecycle Management environment. Indeed, today, we can propose solutions to:

- move the machine performance verification to the left of the development cycle, time-wise speaking

- improve the data, model, and configuration management

- and finally, embed the Digital Twin capability on the machine in the field to manage the operator experience and the machine maintenance.

Hold on – Did you say that you missed the live events we hosted over the past year? No worries. There’s still time to catch-up:

Or, would you prefer to read than listen? Stay tuned over the coming months; white papers will be shortly released on the same topic. Subscribe to our communications preference center to receive an email when that’s released.

A conversation about the role of digitalization in the heavy equipment market

In collaboration with Tom Stone from the specialized IVT International magazine, we brought together the following group of experts to discuss the impact that Simcenter has had on their businesses. Gennaro Monacelli from CNH Industrial, Yohann Brunel from Poclain Hydraulics, Alastair Hayfield from Interact Analysis, and Gaétan Bouzard from Siemens Industry Software Simulation & Testing.

- How digitalization is changing the heavy industry’s way of doing things

- When it comes to design engineering, why does simulation have so much potential?

- Can all the heavy machine multi-physics systems, including electric, thermal, fluid, mechanical, and control, be covered at once by simulation?

- How to reach 100% confidence in the model? With the use of physical data acquisition during test campaigns to support the model calibration.

- How does scalability impact team collaboration within a company and interaction among OEM/Suppliers?

- What’s next in the future of the industry?

Prefer to read about this instead of listening? Check out the article inspired by the above discussion in the Engineer Innovation magazine: Heavy Lifting: Taking Heavy Equipment into the Digital Age

What’s next for your organisation digital transformation?

One of our flagships events is a live session, where we discussed the overall Simcenter solutions and synergies for each of the listed topics above.

We are also thrilled to share how digitalization can streamline your engineering processes and enable them to interact with departments involved in your product design. For that purpose, we address data, model, and configuration management.

On that topic, your questions might be related to how you can:

- accelerate the performance validation of all machine configurations.

- capitalize on the engineering work done to realize the Digital Twin.

- guarantee model coherency and traceability across the enterprise.

Our New Year’s resolution.

Well, yes, it’s a bit early, but we want you to know as soon as possible that our goal is to get feedback from you: your vision, your ideas, and your success stories about Simcenter solutions. We have many ways to honor your comments: Engineering Innovation magazine, Simcenter podcast episodes, and Realize Live conferences.

Feel free to reach out to me directly! I’d love to hear from you!