How Hilti implements active vibration reduction

Active vibration reduction is an innovative safety feature, offered in Hilti’s range of handheld power tools. Why and how did Hilti develop this feature?

Read the complete story to learn how Hilti reduces vibration in its handheld power tools.

Massage chairs are awesome devices to shake and vibrate the stress away from your body. However, while the invention of a massage chair brought more comfort, other vibrating tools solely serve the purpose of breaking down concrete structures. Demolition hammers, for example, are designed to produce vibrations, but you’d never try to get a massage with it!

Excessive vibration cause damage

Vibrations can often be associated with discomfort, dysfunction and failure, and may even cause physical harm. Operators who use building equipment and power tools are too often in prolonged contact with excessive vibrations. They are prone to health problems. Hand-arm vibrations syndrome (HAVS), for example, is a disease caused by the over-exposure to vibrations. It causes numbness, damage to the blood vessels, and a tingling sensation, coupled with pain in the forearms and hands that could lead to the loss of digit dexterity.

Therefore, to reduce the impact of such equipment on the health of operators, manufacturers must now not only create efficient and powerful tools, but also comply with stringent health guidelines set by the International Organization for Standardization (ISO).

Hilti implements active vibration reduction

Hilti is the market leader in demolition technology for construction professionals. It positions itself as a high-quality manufacturer. Hilti engineers develop top-quality, durable construction tools and equipment that combine high performance while safeguarding the operators’ health and safety.

As an example of its strive for safer tools, Hilti has developed handheld power-tools with an active vibration reduction (AVR) functionality. This functionality significantly lowers the vibration sent to the operators by absorbing them through mechanical springs (as shown in the video below).

Simcenter solutions help reduce vibrations

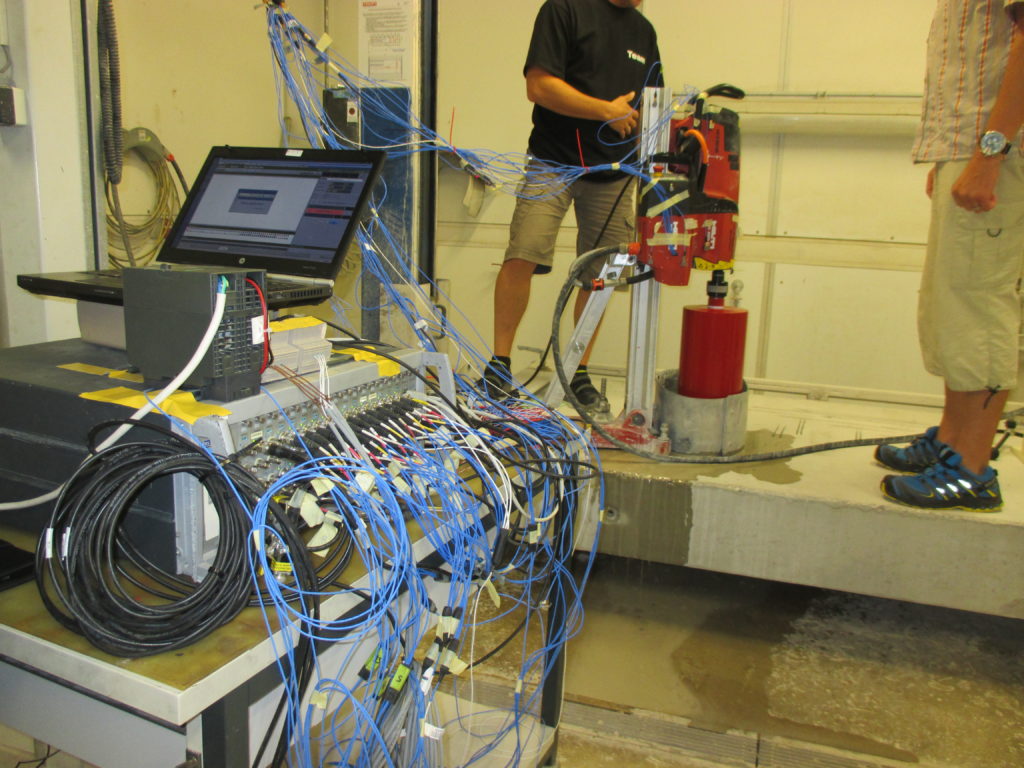

To achieve such innovative adjustments on its products, Hilti relies on Simcenter Testlab testing solutions. Together with the Simcenter SCADAS hardware and the Simcenter Testlab software, Hilti highly optimizes the development and manufacturing process, allowing engineers to test and fine-tune all parameters at any stage of the development cycle.

To preserve the health of operators, Hilti relies on the human body vibration filter add-in in Simcenter Testlab software. It offers a powerful certification tool for analyzing vibrations transmitted to the human body. The application also gives real-time feedback and clearly indicates limit values and/or violations as specified by ISO standards. Among many other testing possibilities, component testing aids in designing high-quality and reliable products. With this, the component designs are fine-tuned before a prototype is made, saving cost and time.

Through testing, Hilti can optimize designs while also making sure every tool will meet standards. Together with Simcenter testing solutions, Hilti continues to develop products that are powerful, efficient and, most importantly, safe to use.

Read the complete story and learn how Hilti reduces vibration in its handheld power tools.