Execute efficient heavy equipment testing campaigns for reliable and comfortable machines

In the demanding world of heavy equipment, the expectations for machine performance are incredibly high. We’re not just talking about machines; we’re talking about the backbone of construction, agriculture, mining, material handling and countless other industries. For these giants, reliability and operator comfort aren’t merely desirable features – they are absolute necessities, directly impacting safety, productivity, and, ultimately, your bottom line.

From my own experience, I’ve seen firsthand how challenging it can be to achieve these critical benchmarks through traditional testing methods. It often feels like an uphill battle, especially when you consider the scale and diversity of the heavy equipment market. We’re dealing with a huge product portfolio, from compact excavators to massive agricultural harvesters, each designed for specific needs and operating conditions. Battling harsh environments, sifting through mountains of multi-physics data, and managing complex design iterations – the hurdles are real and often depressing.

That’s precisely why I’m so excited to share how our comprehensive Simcenter Testing solution is engineered to revolutionize your testing campaigns. It’s about making them not just efficient, but truly effective, bringing clarity and control to every stage – and making life a little easier for the engineers who make it all happen.

The real-world hurdles: when testing heavy equipment feels like a heavy lift

I remember countless conversations with test engineers all around the world, and their stories often echo a similar tune. Some of the challenges I hear the most:

- Battling the elements for data: I’ve personally been on sites where sensitive data acquisition equipment struggled against dust storms, unexpected heavy rains, and the constant vibration from the machinery itself. It often compromised our sensors or even entire data runs. I recall thinking, “It feels like we’re fighting the environment more than testing the equipment,” remembering the frustration of lost data and wasted time. Getting accurate, reliable data in these rugged conditions is a constant struggle, often requiring significant manpower just to babysit the equipment.

- Drowning in a sea of data: Once that data finally makes it back to the office, the next challenge begins. Modern heavy equipment is a symphony of sensors, generating vast amounts of information across different analog and digital sources to analyze the machine behavior. I’ve spent weeks manually validating this data, sifting through spreadsheets, and trying to correlate different sensor inputs. It truly felt like trying to find a specific grain of sand on a beach, and then having to explain what that grain of sand meant to the design team. The volume and complexity make analysis and reporting incredibly time-consuming and prone to human error.

- The costly guessing game of design iterations: And then there’s the design phase. Identifying potential performance issues late in the game means expensive rework, delays, and missed market opportunities. I’ve often wished for a crystal ball to see how a design change would impact NVH or durability before building a physical prototype. Every physical iteration is a significant investment in time and resources, making early, accurate evaluation crucial but often elusive.

But, how to get rid of all those and gain deep insights to take faster decisions? Well, you need to read the rest then 😊

1. Master the field with Simcenter SCADAS RS: data acquisition

When it comes to in-field data collection, you need a system that’s as tough as the equipment you’re testing and flexible enough for any scenario. Simcenter SCADAS RS is exactly that – a game-changer that lets you gather data, even when the conditions are anything but.

So, if you need to capture precise data for your heavy machinery operating in demanding environments, you know how important it is that your data acquisition system withstands the dust, vibrations, and temperature fluctuations of a field. Exactly for this, Simcenter SCADAS RS is certified for ruggedness, meeting stringent standards like IP66/67 for dust and water ingress and robust specifications for shock and vibration resistance. This ruggedness meant you could deploy units directly where the action was, confident in the data integrity.

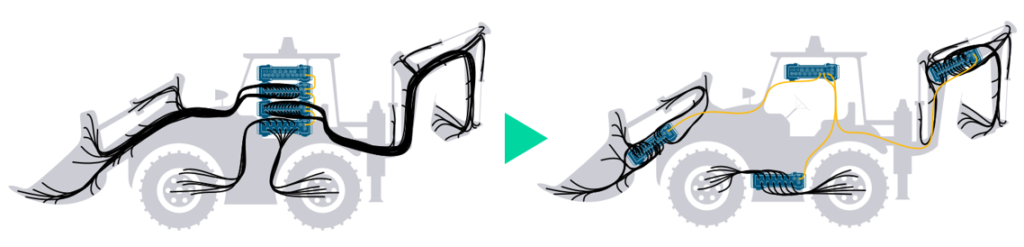

What’s more, the distributed setup for data collection is a game-changer. Instead of long, cumbersome cable bundles from a centralized data logger, you can place smaller Simcenter SCADAS RS units close to the measurement points. This minimizes noise, improves signal quality, and offers incredible flexibility. Imagine testing a massive combine harvester – you can have units near the engine, the cutting head, and the operator cabin, all synchronized, without miles of cable.

This distributed, rugged design also unlocks the possibility of unattended data acquisition and remote monitoring. So, you can set up your tests and then monitor the data streaming in real-time from a safe distance, or even from their office. This capability is invaluable for long-duration tests or those in hazardous locations. It saves immense time, improves safety, and ensures you capture reliable data, every single time, without constant human oversight. It’s about being where the action is, without actually having to be there. Here I drop a link to one of my previous blogposts where I talked about Improve your measurement quality with remote data acquisition and automated data validation.

2. Unlocking deeper insights with Simcenter Testlab: analysis that tells a story

Once that high-quality data is collected, Simcenter Testlab steps in to transform it from raw numbers into a clear, actionable narrative. It’s where the “why” behind the numbers becomes apparent, helping us understand complex phenomena.

human body vibration aspects.

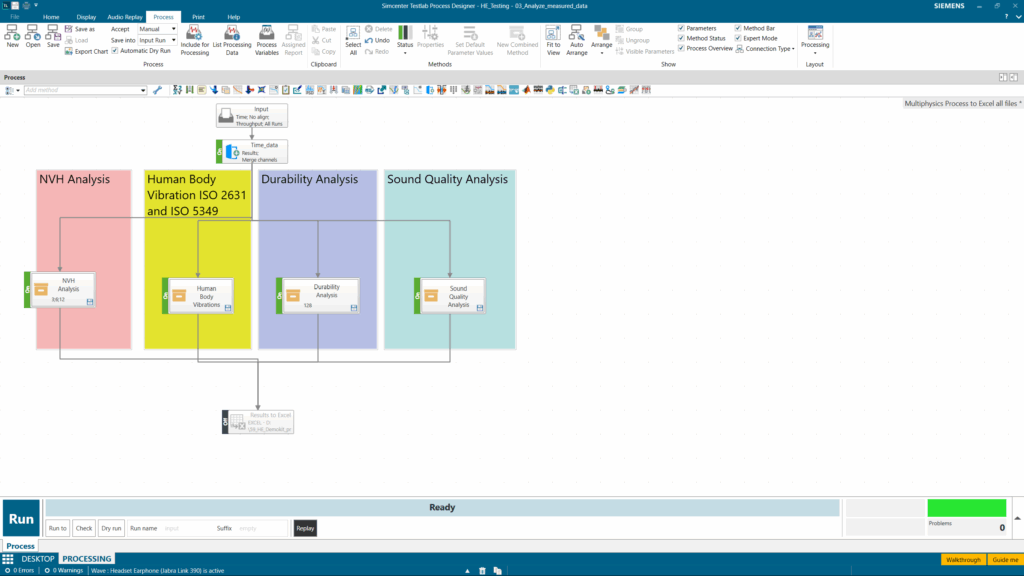

This step is crucial to focus on driver comfort and vehicle durability as important performance indicators. With Simcenter Testlab, you can take the vast amounts of NVH and durability data collected from test machines and not just process it, but truly understand it. Simcenter Testlab serves as an effective data analytics tool for data validation, advanced NVH, and durability.

It can automatically validate incoming data streams, flagging any anomalies, and then dive deep into multi-physics analysis. This allows them to identify specific vibration sources, understand their propagation paths through the chassis, and pinpoint how they might affect driver comfort or component lifespan. It’s not just about knowing there is a vibration; it’s about understanding its root cause and how to mitigate it effectively.

By considering all these, let’s see Simcenter Testlab in action where I’ll be validating some measured runs by considering speed-based checks and anomaly detections, e.g. spikes, drifts, offsets, flat lines… Chery on the cake: I’ll also show how to modify descriptive annotations easily for each measured run in Simcenter Testlab.

Beyond analysis, Simcenter Testlab is also a powerful automated data retrieval, processing, storing, and publishing tool. This means less manual effort in managing your test data. It can automatically pull data from various sources, apply predefined processing chains, store it in an organized database, and even generate customized reports for different stakeholders. This streamlined workflow ensures that insights lead directly to improvements, accelerating decision-making and empowering engineers to focus on engineering, not paperwork.

Let’s take a step forward with Simcenter Testlab by analyzing measured data with NVH, durability, sound quality and human body vibration aspects – all in the same processing flow: the same software, no data conversion…

Here follows a link to a cool blogpost about the automation capabilities of Simcenter Testlab: More efficient testing in 4 easy steps – Simcenter Testlab Workflow Automation (TWA)

3. Innovating early with digital NVH engineering: building better before breaking ground

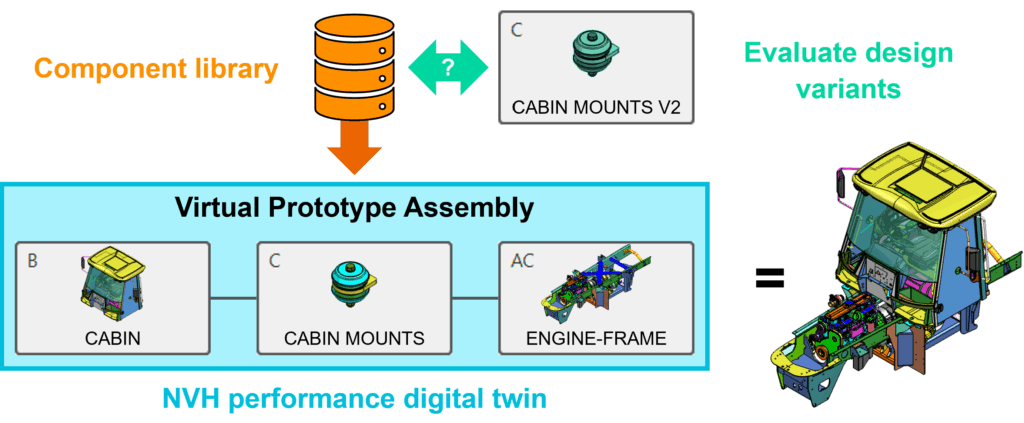

I’ve often discussed with engineers the challenge of designing complex heavy equipment with components sourced from various suppliers or developed by different internal teams. Traditionally, ensuring the overall NVH performance of the complete machine meant waiting until a physical prototype was built, then testing and reacting to issues – a costly and time-consuming process. This is where virtual prototype assembly (VPA) comes in, revolutionizing how we approach early design.

Imagine being able to digitally “assemble” your heavy equipment from its individual components, each represented by its NVH characteristics. This modular approach allows you to take the noise and vibration “fingerprints” of an engine from one supplier, a transmission from another, and a cabin design from your internal team, and combine them virtually. You can then predict the overall NVH performance of the complete machine before anything is physically built. This is incredibly powerful for evaluating how different component choices or design modifications will impact the final product’s sound and vibration.

The following use case will show you how you can benefit from VPA solution in Simcenter Testlab.

The tangible benefits: delivering superior equipment, faster, and with a smile

Our goal with our Simcenter Testing solutions is obvious: empowering you to deliver superior heavy equipment to the market. By integrating these advanced tools and methodologies, you’re not just improving processes; you’re transforming your product development.

The return on investment (ROI) we can count on here by considering all the advantages:

- Significantly improved efficiency: Your teams spend less time on manual tasks and more time on innovation, thanks to streamlined workflows, automated analysis, and remote capabilities.

- Substantial cost reduction: Catching issues early means fewer physical prototypes, less rework, and a direct impact on your development budget.

- Enhanced reliability and durability: Comprehensive, accurate testing leads to more robust and long-lasting equipment that performs flawlessly in the field, building trust with your customers and reducing warranty claims

- Superior operator comfort: By meticulously addressing NVH and human body vibration, you create machines that are not only powerful but also a pleasure to operate, boosting productivity and operator well-being – a key differentiator in today’s competitive market. This can lead to improved operator satisfaction

- Faster time to market: Accelerate your product development cycle, allowing you to innovate quicker and respond to market demands with agility, staying ahead of the competition and potentially shortening time-to-market by several months.

Ready to transform your testing?

It’s about moving beyond traditional limitations and embracing a future where efficiency, reliability, and comfort are built into every machine, right from the start. It’s about empowering your engineers to do their best work, delivering products that truly stand out in a crowded market.

Want to dive deeper and see how this integrated solution can truly transform your heavy equipment testing? We will look forward to talking to you in details!