A masterclass in engineering excellence and innovation of farm equipment at Crucianelli

How a third-generation Argentinian farm equipment manufacturer embraced the entire Siemens Xcelerator digitalization portfolio to meet ambitious 2030 goals.

Currently at 8.2 billion, set to hit 9 billion in 2037 and 10 billion by 2058, the global population is booming and one thing the world will need for this surge in people is…food. UN experts, amongst others, stress the fact that the global agricultural industry needs to increase production capacity rather significantly (some say 3% annually) to ensure a sustainable and food-secure future for all.

One clear path to doing this is sustainability intensification or increasing food production capacity while minimizing environmental impact. Another sure bet is the investment in the agricultural industry and smaller farmers in particular, giving everyone in the farming ecosystem the same advantages for viable incomes, access to best- and smart-climate practices, and a route to ample and better-quality food for all.

Although these ideas might sound rather straightforward on paper, the growing global food security crisis is anything but that. Ask anyone who works the land day-in/day-out and the answer you will get is that increasing productivity sustainably is not an easy or obvious task. The challenges for farmers everywhere are many: climate change, drought, floods, geo-political issues, regulations, rising costs, labor shortages, failed crops, volatile market prices…

Farming is in the blood

That being said, most farmers love and respect their land and this passion for farming is usually passed from generation to generation. From the massive wheat and corn farms in the American Midwest to the rolling wheat fields of Europe to the large-scale cereal, soybean, and sunflower farms of South America, farmers will tell you that they wouldn’t live any other way. That is certainly the feeling you get when you zoom into Armstrong, Argentina, a small rural town in the heart of Argentina’s farming community and the home to Crucianelli, the country’s market-leading seeder and planter manufacturer.

“Crucianelli was founded almost 70 years ago. My father, an Italian immigrant, Don Nazareno, started working in an old workshop, really just a small shed the size of a car garage, repairing machines for local farmers and manufacturing his own agricultural machinery. His thinking was that it would be good for the environment, and profitable and sustainable for the local farmers,” say Raúl Crucianelli, Chairman of the Board, Crucianelli Group.

Committed to technology for long-term farming sustainability

The mix of sustainability, technology and a strong sense of community has always been central to the Crucianelli Group.

“When I joined the company over 50 years ago, it marked a period of professionalization for the company. In those days, there were no engineers, let alone accountants in administration. So, I thought it would be a good idea to start promoting technology, and the first engineer joined the company,” adds Raúl Crucianelli.

Today, the tradition continues, and a company-wide digital transformation is driving Crucianelli forward. The engineering team numbers approximately 100 people, many who are (very) young, recently graduated digital natives. Raúl Crucianelli has handed the day-to-day reins over to his son and daughters and they are focused on a future that is clearly digital…

Meet with the Crucianelli family members and learn how a third-generation Argentinian farm equipment manufacturer embraced the entire Siemens Xcelerator digitalization portfolio to meet ambitious 2030 goals.

A transformative digital journey

Crucianelli has embarked on a transformative journey to modernize its engineering and manufacturing processes. By integrating simulation tools, structured training, and digital backbone technologies, the company significantly reduced development time and enhanced product quality, which culminated in the successful launch of the Dómina seed drill.

Behind this impressive new agricultural machine is a strategic digital transformation aimed at modernizing engineering workflows, reducing development time, and preparing the company to meet its 2030 goal: to position itself among the top five most important seed drill manufacturers worldwide.

Breaking through the development ceiling

Like most farmers around the world, the Argentinian and South American farming communities require equipment that performs day-in-day-out. With more and more technology creeping into the agriculture industry, Crucianelli faced increasing demands from the sector for more seeding precision, durability guarantees, and speedier performance when it comes to agricultural machinery design. Plus, the team needed to rethink their development process to meet some ambitious goals, including reducing time-to-market and improving structural reliability under harsh field conditions.

In 2018–2019, Crucianelli recognized that its traditional product development approach had reached a ceiling. “We began to look around the world to see what the cutting-edge technologies were,” says Gustavo Crucianelli, CEO. “And well, Siemens came along to help us make that leap we wanted to take.”

This marked the beginning of an important partnership that would redefine how Crucianelli designs, simulates, and validates its agricultural machinery.

Building the digital backbone with Teamcenter and SAP

In 2021, Crucianelli initiated a major digital transformation by implementing TeamcenterTM with SolidWorksTM, a software that the company had been using for computer-aided design (CAD) and data management for about 20 years. But with advanced engineering challenges requiring significantly more computing and data management capacity like detailed structural analysis and fluid mechanics, Crucianelli decided in 2021 to migrate to more advanced tools from the Siemens Xcelerator portfolio, namely SimcenterTM and DesigncenterTM NXTM. Needless to say, the migration proved to be challenging.

“Over the years, we began see the limitations we had. We knew we needed a big change when it came to digitalization,” explains Gustavo Crucianelli. “We knew the Siemens solution was the ideal application, but we needed local partners to help us adapt it. This is where our local Siemens experts from Simecanic / X-Plan and Descar Argentina came into the picture for advanced simulation capabilities.”

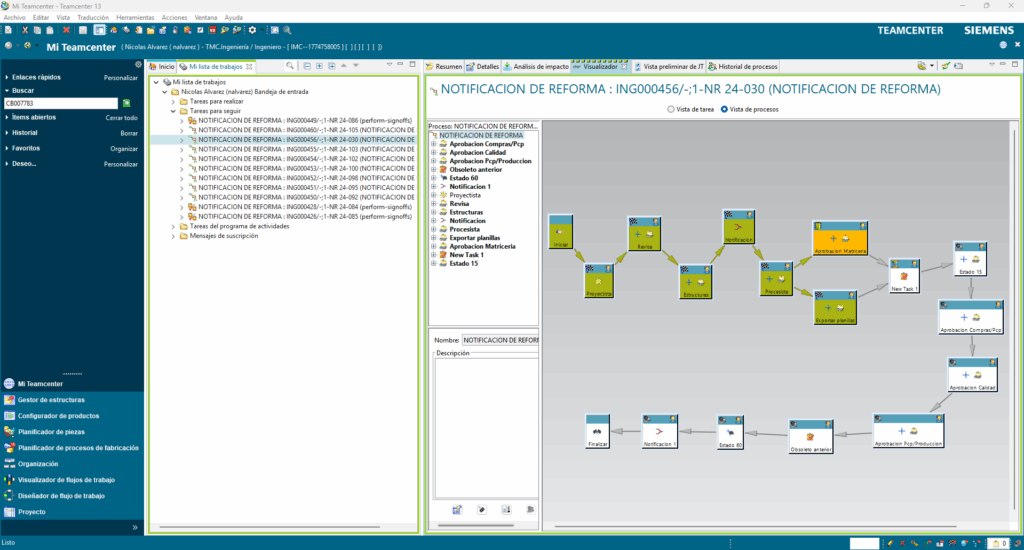

Teamcenter: process view.

From the dealer to the production line: a single source of truth

To start to streamline collaboration between engineering, production and the supply chain, the company adopted Teamcenter as its product and process information management backbone. With 23 people in the engineering department and 16 users on the plant floor, Teamcenter ensures that critical data is not only centralized, but also highly accessible through the web-based Teamcenter Active Workspace interface, enabling real-time visibility and traceability across teams. Production-wise, at the heart of the Crucianelli digital backbone is the use of Teamcenter Manufacturing, which helps plan and manage detailed manufacturing processes processes including product engineering (E-BOM management) and process engineering (M-BOM and Bill of Process (BOP) creation).

The results are evident:

- A scalable system that grows with the company without requiring large infrastructure investments.

- Greater efficiency, by cutting costs through the elimination of physical prototypes and errors.

- A collaborative environment that streamlines validation across departments and speeds up time-to-market.

With Teamcenter, Crucianelli reaffirms its commitment to innovation and positions itself as a benchmark in building the Industry of the Future in the agricultural sector.

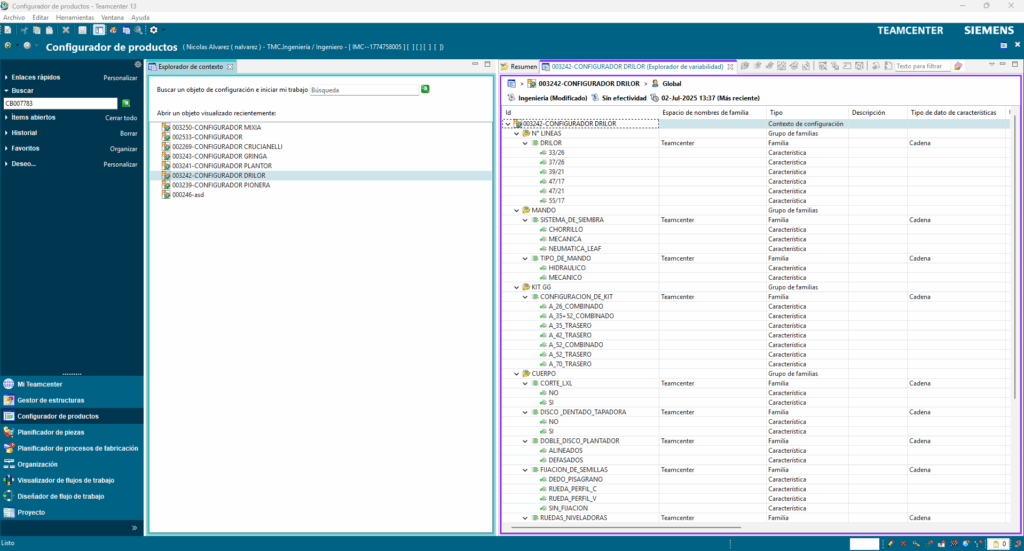

Because customers can custom-order new products like the Dómina directly from one of the 70 local Crucianelli dealers, Crucianelli counts on the Teamcenter Product Configurator to further enhance flexibility. “Adding the Teamcenter Product Configurator module lets the engineers over-design the digital twins150%. This makes it much easier to handle customer configurations and the inherent complexity of the Crucianelli products,” states Lucas De Cecco, owner and director, Descar Argentina.

In addition to Teamcenter Product Configurator, another challenge was integrating the extensive dealer network into the Siemens digital roadmap. This included a complex, customized integration with SAP which is used onsite at the Crucianelli dealers. Today, the dealers customize the products online using Teamcenter configuration rules. The SAP integration provides a seamless connection between design, variant management, BOMs, and production, optimizing the entire enterprise workflow at Crucianelli.

Teamcenter: Product list management

“Siemens played a pivotal role in supporting us when it came to complex configurations with the Siemens Xcelerator tools as well as the SAP integration. Their specialists provided essential guidance, ensuring accurate data alignment and efficient system operation”, emphasizes Lucas. “I might add that we started the process using spreadsheets but now have it highly automated as well. It wasn’t an easy task.”

The final result is a scalable system that can grow with the Crucianelli Group without significantly larger infrastructure investments. A vital part of the Siemens Xcelerator solution, the Teamcenter PLM backbone improves efficiency and solidifies a collaborative environment that streamlines validation across departments and speeds up time-to-market.

Greater efficiency, by cutting costs through the elimination of physical prototypes and errors.

Meet with Lucas De Cecco, director and owner of Descar Argentina. Discover how this Siemens Smart Expert Partner helps Crucianelli implementing a complete digital backbone with Siemens Xcelerator.

Empowered engineers through step-by-step training in model-based development

While the Descar Argentina delivered training to Teamcenter users, things on the engineering side were busy as well. Experts from Simecanic / X-Plan led comprehensive training initiatives to help the young team of engineers get up-to-speed with advanced skills in structural analysis so they would be comfortable in the new way of working in a model-based design strategy using Designcenter NX and Simcenter 3D. One of the first things they did is build a 1D beam model in under two weeks to quickly identify weak points in chassis designs.

“We used simple modelling techniques like creating 1D beam models in Simcenter 3D to train engineers and quickly identify weak points in the chassis,” explained César Destefanis, Engineering Manager and Business Development for Simecanic / X-Plan. “It is a straightforward way to refine the design and address specific issues with greater accuracy.”

Further training focused on meshing techniques, model reduction, and results interpretation. The young Crucianelli engineers gained hands-on experience through a blend of online and on-site sessions in Armstrong, Argentina as well as field training with operational machinery.

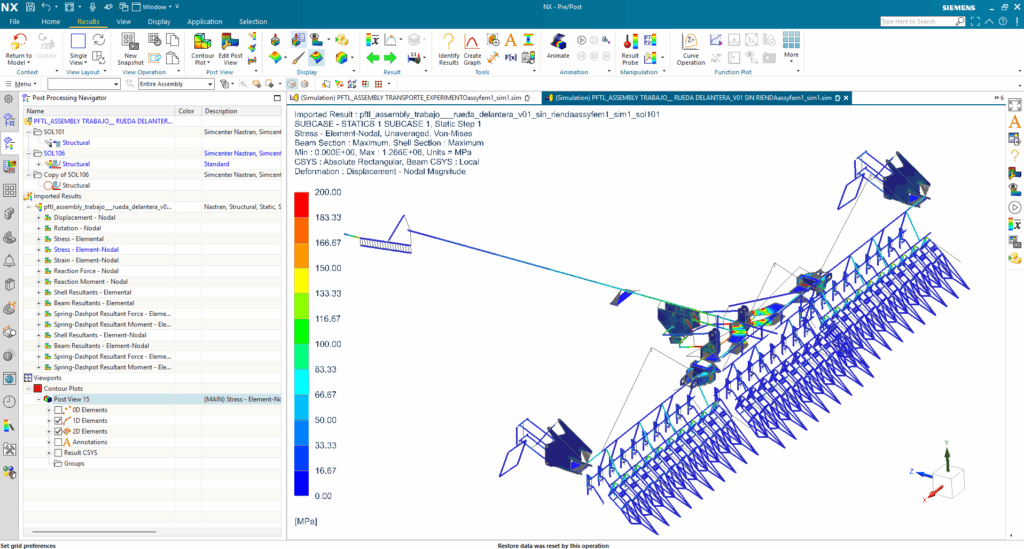

Designcenter NX: 1D beam model built in less than 2 weeks and used to take early engineering decisions

In the end, the team could determine the best-possible wheel placement and load distribution using the basic model and work out further details with 2D/3D meshes and optimization rounds, taking advantage of the integration between Designcenter NX and Simcenter 3D. The end result was a validated model of the structural behavior including transportation and on-field performance.

A dual-track simulation strategy for system analysis

The team at Crucianelli adopted a dual-track simulation strategy in Simcenter 3D by separating motion and structural analysis to streamline workflows. One team worked on motion analysis to simulate machine operations, while the structural analysis team focused on mechanical integrity. Although electrical and hydraulic systems were not yet integrated into the model, the groundwork was there for future system expansion .

Adds Cesar Destefanis, “Simcenter provides the same environment with the same language and same knowledge for both motion work and FEM. This speeds up the work between different disciplines. And the training effort is less.”

One aspect that should be noted is that the training focused on knowledge transfer between experienced employees and the new engineers as well.

“At Crucianelli, there are many very experienced employees who have learned ‘on the job’ for years. It was important to preserve their ‘hands-on’ expertise while embracing modern tools like Simcenter. Some of these people knew what would work and what wouldn’t just thanks to their years of experience. It was a crucial factor we needed to take into consideration,” states César Destefanis.

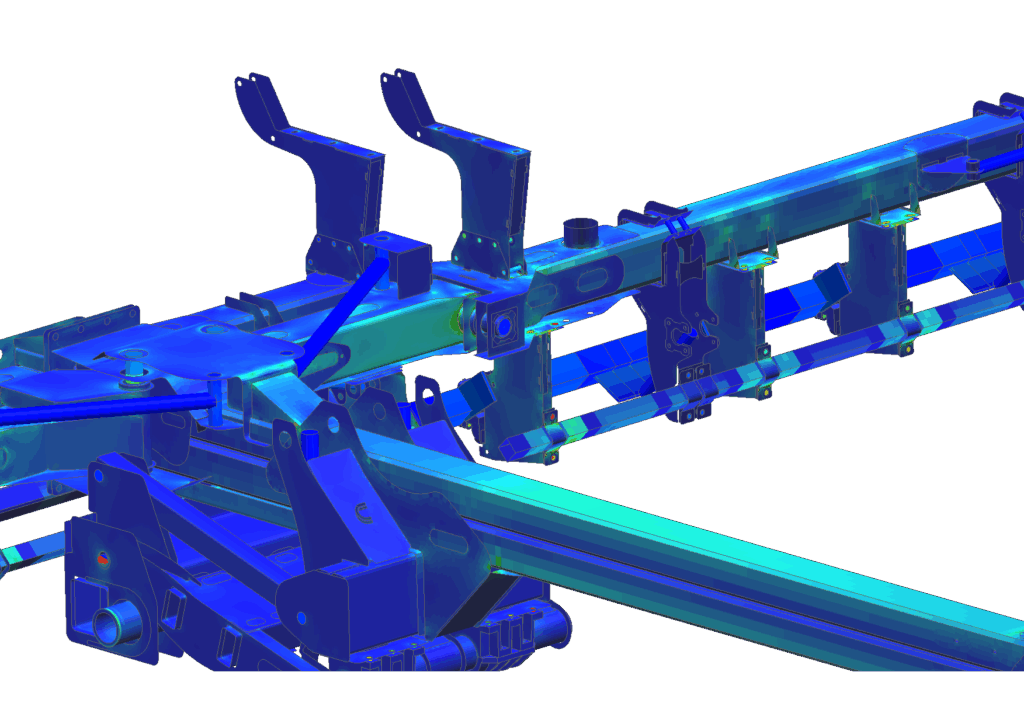

Simcenter: Stress analysis of the Dómina machine performed with Simcenter 3D

Enter the Dómina

The company’s latest seed drill, the Dómina was developed using the Simcenter portfolio. Scheduled to go into full-scale production in 2026, like most other Crucianelli products, the Dómina is tailorable to specific farming techniques, soil and crop types, and terrains and climate conditions.

This is especially important in Argentina where 90 percent of the farmland is no-till. No-till farming is an agricultural technique for growing crops without disturbing the soil by plowing or tilling. Argentina has the highest percentage in the world for this more ecological farming practice.

“The Argentinian farmer is the one who got us where we are today,” explains Crucianelli. “Argentina has the most direct use of no-till agriculture in the world and some very demanding natural conditions. Our agricultural community in the Argentinian countryside is the largest contributor to the gross domestic product. It must be the most efficient sector and must adapt to change; it can’t slow down or stall. Our farmers must plant with the best-possible conditions to achieve high productivity on a large scale,” states Gustavo Crucianelli.

A real-world example of digital engineering excellence, the Dómina, totes a 3.2 m width for transportation, versatile 8.5, 9.5 or 10.5 m full-out working width and, most importantly, specifically engineered features to maximize sowing and fertilization quality.

Crucianelli farmers will be able to optimize every acre with a new Dómina. tailorable to specific no-till farming techniques, soil and crop types, and terrains and climate conditions.

“We are really proud to have worked on the Dómina project with the Crucianelli team from scratch” says Destefanis. “And it was implemented entirely in Simcenter 3D which opens numerous engineering opportunities for the digital twin in the future as well.”

Meet with César Destefanis, Engineering Manager and Business Development for Simecanic / X-Plan. Discover how this Siemens Smart Expert Partner helps Crucianelli accelerating innovation, and improving competitiveness with Siemens Xcelerator.

Subsystem engineering and component-level validation

Subsystems such as the side support wheel, wings, tank supports, and traction bar were modeled and analyzed in Simcenter 3D as well. Engineers conducted linear static analyses to validate the overall structural performance. (Note: the more complex nonlinear analyses remain company confidential.) This FEA approach allowed for precise evaluation of each component’s behavior under load conditions, contributing to a robust and reliable final design.

Detailed stress analysis was performed on the assembly of central and articulated arms with the traction bar, ensuring mechanical integrity under dynamic conditions. The team also simulated both folded (transport) and unfolded (operating) configurations using 1D meshing.

With help from Siemens, Crucianelli engineers also tackled the complex challenge of designing a stiff yet articulated chassis capable of handling heavy seed loads and dynamic field conditions. Engineers focused on torsional stress analysis using 1D meshing techniques to ensure stiffness and durability during both transportation and field operations.

Full assembly simulation: scaling with Siemens partner expertise

The final result was a full assembly simulation involving 50 to 80 components and over 1 million finite elements (1D, 2D, and 3D meshes). The complete FEM model was built in Simcenter 3D with CAD association, enabling comprehensive stress assessment across the entire machine.

One of the most remarkable outcomes was significantly reduced development time thanks to the improved efficiency, elimination of errors and overlaps as well as expensive physical prototypes.

Notes Juan-Pablo Cittadini, Engineering Manager, Crucianelli Group, “The time required for this and the number of prototypes and field tests was reduced considerably—by more than 40%—thanks to the experience gained from the projects we have carried out so far.”

With improved time-to-market and faster return on investment, the team plans to continue refining workflows and deepening technical expertise to sustain this momentum with future product launches.

Improving existing machine performance

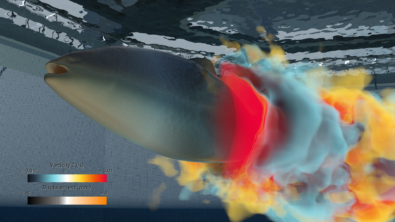

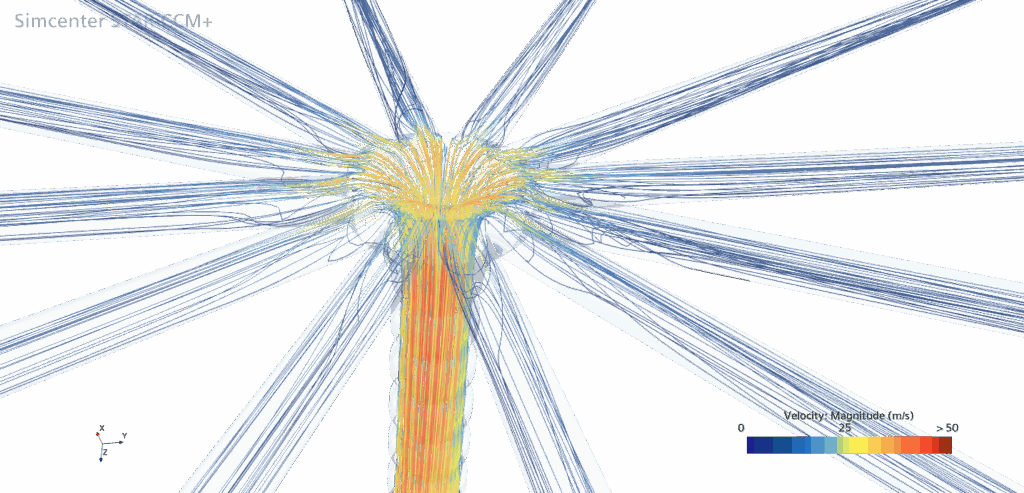

Other advanced Simcenter tools are also used to improve the performance of existing machines. That’s the case with the Plantor, where the precise seed distribution flow was improved and optimized with Simcenter STAR-CCM+ CFD software.

Seed drill performance depends on multiple factors from seed and soil type to tractor speeds, and weather conditions. Modelling something like this requires expert support and innovative thinking and the right tool in Simcenter STAR-CCM+.

“We had to model specific seed trajectories under various working conditions. This meant we needed to count on Siemens expertise as well as our own when helping Crucianelli develop specific resources like a CFD-DEM hybrid engineering tool in Simcenter STAR-CCM+ to support a complicated simulation like this,” states Destefanis.

Based in Simcenter STAR-CCM+, the CFD-DEM tool combines Computational Fluid Dynamics (CFD) (which models the air flow) with the Discrete Element Method (DEM) (which models the seeds) to simulate precise seed movement in the seed drill itself.

“We started with a CFD study in Simcenter STAR-CCM+ to determine the various flow dynamics, and after obtaining results with that model, we coupled it to a DEM model of the various seeds to get our final results,” adds Destefanis. This creative video explains how the particules are transported in the Plantor’s seeds distributor.

Simcenter Star-CCM+: particles distribution along the pipes and main seeds distributor

Digital factories with Tecnomatix Plant Simulation

Looking ahead, Crucianelli is currently focusing on completing the digitalization of their production site. “I believe that the future with Siemens lies in the complete digitization of the plant,” said Gustavo Crucianelli. “We need to start thinking about simulating all production processes and determining the most efficient way to produce them”.

This includes additional robotics and a full-fledged Tecnomatix Plant Simulation of the plant and production lines as well as optimized logistics. Eventually, the big plan is to replicate digital twin capabilities across the Crucianelli Group.

“I think that Siemens partners like Simecanic / X-Plan and Descar Argentina are key because they know us, and they know the product,” states Gustavo Crucianelli. “They helped us not only learn the simulation and PLM software features, but also get the most out of it. Without our partners, it would not have been possible to achieve what we have achieved today in a company like Crucianelli.”

Conclusion: Siemens Xcelerator for Future Innovation

Crucianelli’s journey (to date) demonstrates how strategic thinking, intensive training, advanced simulation, and a digital mindset can empower a company and its people to innovate faster, smarter, and more collaboratively.

“The advantage of Siemens today is that everything is within the Siemens Xcelerator platform—from product conception and design and engineering to the end of the product cycle,” emphasizes Gustavo Crucianelli. “It is all integrated — all the simulation software, Teamcenter, and everything related to production.“

“Siemens will remain a key partner in our journey, providing the tools and expertise to help our third-generation company innovate in an increasingly complex and competitive market, concludes Gustavo Crucianelli.

Want to know more about the Crucianelli story?

• Official video

• Written case

• Press release

About Siemens Smart Expert Partners:

César Destefanis

Engineering Manager and Business Development at Simecanic / X-Plan

Lucas De Cecco

Owner and director, Descar Argentina