Corrdesa – Reducing rust in critical aircraft components

Minimizing the impact of corrosion with Simulation

Corrosion is a common problem for many different types of metal products. You’re most likely to have experienced it in the form of rust in an older motor vehicle. It’s a nuisance that at best can be unsightly and affect the car’s value, and at worst reduces structural integrity and compromises safety.

But what about corrosion in aircraft? Most planes are designed to operate for several decades – much longer than the average car – and are often subject to more of the moisture and climate conditions that accelerate corrosion.

With air safety so critical, manufacturers and operators can’t afford to take any risks. Planes must be regularly inspected, and corrective action must be taken to effectively deal with any corrosion.

But this is neither straightforward nor cheap.

The cost of corrosion

The United States Air Force spends over $20 billion annually on corrosion. This is approximately 20% of its total maintenance costs and accounts for 24 million hours of downtime. Some military aircraft, such as the B-52 Stratofortress, are still in use after 70 years. This makes it even more important to ensure that modern planes are built to withstand corrosion as much as possible throughout their expected lifespan.

Corrosion-resistant design

Corrdesa was established in 2011 to use simulation to predict corrosion and help manufacturers make better decisions in terms of material selection and design optimization. CEO Dr Alan Rose is a recognized expert in computational engineering with over 30 years of experience across aerospace and defense, chemical and process and nuclear industries. He has led the development of Corrosion Djinn®, Corrdesa’s cutting-edge SaaS (software as a service) platform for managing electrochemical data and quantifying corrosion risk.

Dr Rose and his team collaborated with Simcenter Engineering Services to integrate Teamcenter and Simcenter STAR-CCM+ software with Corrosion Djinn® to apply the data to 3D models of aircraft for the US Air Force. “Simcenter STAR-CCM+ has several built-in models, ideal for corrosion modeling, which saved us a significant amount of time,” he says. “And as the US Air Force was already using Teamcenter, it made it easy to seamlessly integrate with their existing systems.”

Detailed corrosion analysis in minutes

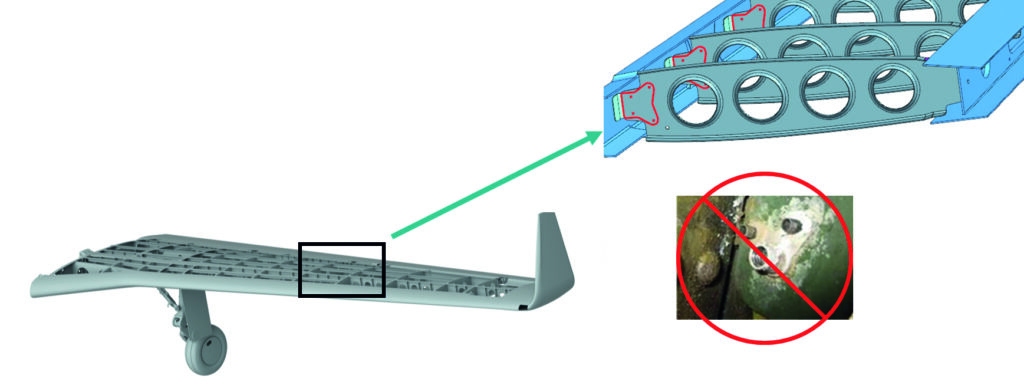

Working alongside US Air Force aerospace experts, Corrdesa and Simcenter Engineering Services defined templates that sped up the modeling of new designs by automating geometry and computational mesh creation and setting boundary conditions with Corrosion Djinn® data. The workflow between Simcenter STAR-CCM+, Teamcenter and Corrosion Djinn® allowed non-CFD experts at the US Air Force to create 3D models with corrosion analysis in a matter of minutes.

This gave a prediction of the amount of corrosion with different types of materials and different barrier coatings. All within the time it takes to make a cup of coffee.

Hundreds of millions of dollars saved

Ensuring that new aircraft designs are as corrosion-resistant as possible is essential for keeping future costs down for the US Air Force. Combined with cutting down testing through accurate corrosion simulation, this is expected to save them hundreds of millions of dollars.

Just one design issue of the F-22 Raptor cost $228 million to solve. The new toolset would have picked this up much earlier in the design phase and avoided most of the costs.

But Corrdesa’s collaboration with Simcenter Engineering Services isn’t only about protecting future aircraft from corrosion. The same solution is being used to analyze repair options for existing aircraft, including the U-2 and C-17. This will allow the US Air Force to keep these in operation for longer and reduce the overall maintenance costs.

From the air to the ground and beyond

Dr Rose is keen to extend the service to other branches of the US military and beyond. “We’re in discussions with automotive OEMs that are going through digital transformation,” he says. “Although many already have virtual models for analyzing stress, aerodynamics, heating and batteries, they don’t have the corrosion modeling capabilities that we provide.”

To find out more, read our detailed case study and review Corrdesa’s Computational Corrosion Analysis presentation. Corrdesa also regularly attend Realize Live and you can read their thoughts on the most recent conference here.