Composites Curing: A Recipe for Success

Have you ever thought about the complexity of baking a cake? Set the oven temperature too low it turns out half-baked, too high or left in the oven too long it will be charcoal. There is an art to baking a cake, but with the right recipe, you can consistently bake a great cake. The manufacture of thermoset composites (referred to as composites curing) has to-date followed a very similar artistic process, and the challenge is to find the right recipe.

If you follow the evolution of engineering, most of the recent innovations are in the field of materials science such as additive manufacturing and in this instance composites. Recently we had the opportunity to meet with Jim Gilbert, a recent graduate from KU Leuven with a master’s in materials engineering who won an award for best student presentation for his master’s thesis on the “Simulation of Thermoset Polymer Composites Curing” (attached below) last year at Sampe Europe, and as you might expect he had a lot to say on the subject.

Originally from Ottawa, Canada, Jim Gilbert studied chemistry and physics as an undergraduate student, giving him a background in pure science. However wanting to put his knowledge in practical everyday applications led him to the field of materials engineering, and in particular composites. Jim enrolled in KU Leuven which has had a strong presence in the field of composites research for many years with its Composites Research Group. For his thesis, he worked closely with our Siemens team in Leuven which has had a long-standing relationship with KU Leuven and relied heavily on Simcenter 3D for simulation.

Thermoset composites as their very name indicate receive their rigid structural properties when they are cured in an autoclave (check out this article on composites manufacturing for more info), however during this manufacturing process often cure-induced deformations occur that adversely affect the performance of these structures either by distorting the final shape or affecting the overall service life by reducing the maximum tolerable load.

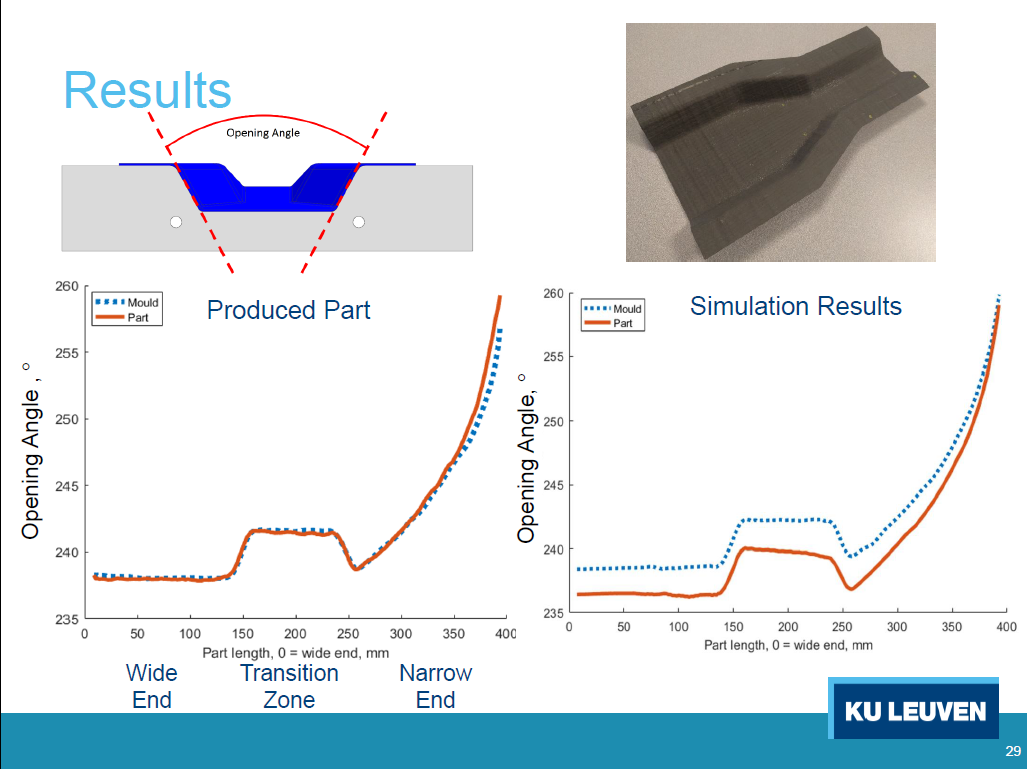

Jim’s project was to predict and account for these distortions and by doing so move composites curing from an art form to more of a science. The way he did this was to perform numerical simulations with Simcenter 3D and in particular our Samcef solver. His approach was to simulate the distortion in a two-step methodology.

The first step was to simulate the thermal curing simulation and the second step was a mechanical simulation where the cured part was subject to different load cases.

To be able to predict the thermal distortions Jim chose to correlate widely available experimental data on fast-curing aerospace-grade resins and slow-curing automotive-grade resins with numerical simulations. The details of his correlation are available in his presentation below but what he found was that there was a good correlation, enough to validate that his approach was valid.

One of the keys to achieving this correlation was the ability to take theoretical models and put them into the software. This was one of the key aspects of why Simcenter 3D and Samcef, in particular, was so useful to him, the ease of use with which he could input specific cure laws (such as this) that help the design and fabrication of composites. This was all the more so given his relative inexperience with Simcenter 3D.

As Jim was quick to point out, the results he received were only preliminary, but given more time he could probably have achieved a closer correlation. But what is without a doubt is his approach, which is that a key method for eliminating distortions in composites curing is to first simulate its manufacture and account for these distortions. The implications for industry are clear, in that this can take smaller-scale “artistic” production into industrial-scale predictable production.

Oh, by the way…

As if receiving his master’s degree last summer wasn’t enough to demonstrate his serious work ethic, Jim was also chosen to represent Europe next week at the global Sampe conference in Long Beach, California. And I would say that as a fellow Canadian, I’m perfectly ok with him representing Europe, even if our southern neighbors may confuse him as one of their own!