Accelerating Airworthiness Certification

Plug ‘N’ Play

Electric aviation has been in the news for a few years now, and we at Siemens have played our part. However as with all innovations, there are risks, and mitigating these risks involves accelerating airworthiness certification.

Beyond the obvious environmental benefits, why has there been such a boom in the development of electric planes? Simply put, electric propulsion is a game-changer; electric motors have fewer moving parts, are easier to maintain, and can “plug-in” to an existing aircraft. This, therefore, lowers the otherwise prohibitive cost of entry for would-be manufacturers.

Such innovation and radical departures from the past while revolutionary and necessary, are also risky. This is doubly so with aviation as the risks associated with failure can often be catastrophic; so it makes sense that organizations such as the FAA can be reluctant to certify new innovative designs.

Not My Way, Your Way

However recently the FAA amended the Part 23 requirements for airworthiness and changed how airplanes are certified. These amendments mean moving from a prescriptive approach to performance-based standards via generally accepted MOCs (Means of Compliance). This amendment, while small, is also a game-changer.

Previous MOCs relied on tried & true procedures which led to conservative approaches and thus incremental changes based on existing technology. With regards to propulsion, this often meant seeking more efficiency from gas turbine engines. With the new rules, airframers need only show their aircraft meet performance-based criteria, and the means of propulsion becomes irrelevant.

Change the Game: Accelerating Airworthiness Certification

This is where Bye Aerospace, an electric aircraft startup comes into the picture. They wanted to capitalize on these two innovations: new rules, and new propulsion to develop their all-electric trainer. As stated in this testimonial, the ability to innovate, develop & compete is made possible by Siemens software. As their founder George Bye puts it, Siemens software is a technology enabler.

In the video, Jim Forrester, their Director of Design & Engineering, describes how using NX, they developed a top-down design approach. This increased their efficiency with orders of magnitude and a fraction of personnel compared to other airframers.

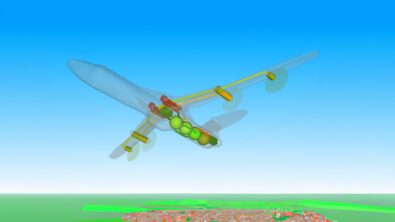

Bye Aerospace’s ambition is to be the first all-electric aircraft to be certified by the FAA, but how? By extending their top-down design with NX & Fibersim into simulation with Simcenter 3D.

Next week, on April 23rd, I will be hosting a webinar on how Simcenter can help accelerate airworthiness certification (register here). A key requirement is an integrated end-to-end structural development process. I am pleased to have Daniel Hinson, Lead Composite Structures Engineer at Bye join me to describe their innovative integrated approach.

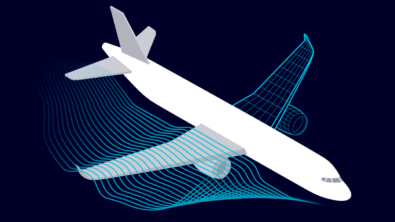

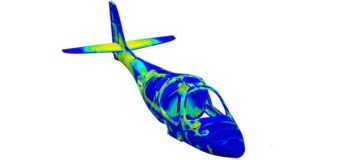

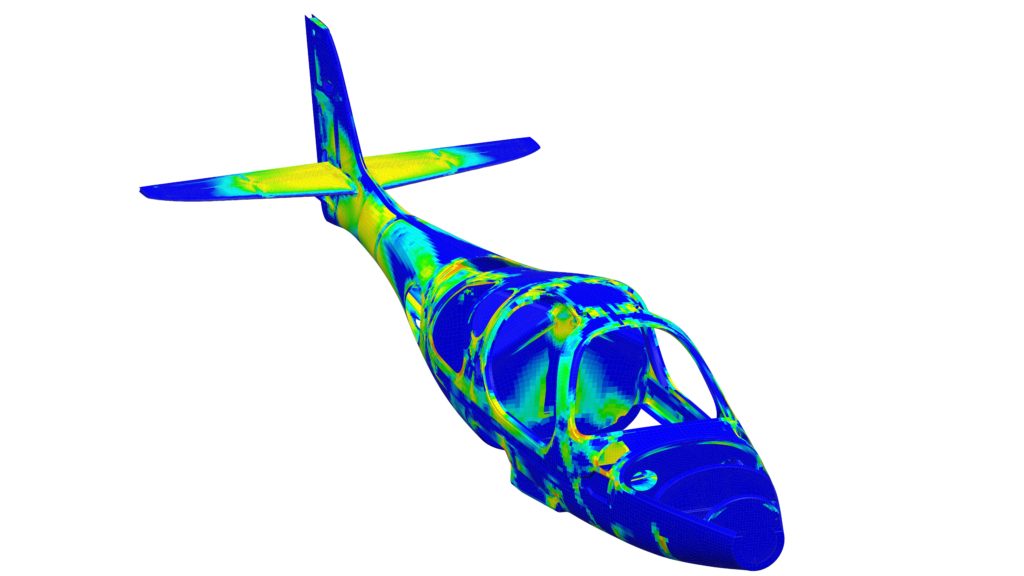

You will learn how Bye is extending its top-down design into simulations to achieve airworthiness certification and how the structural assessment of an aircraft is critical to achieving this.

In addition to gaining a deeper appreciation of Bye’s process, you will also learn how such an integrated CAD-CAE approach combined with innovations such as virtual material characterization, margins of safety calculations and flutter analysis can help you accelerate airworthiness certification.