Efficient Rotor Dynamics for Multi-Stage Turbomachinery

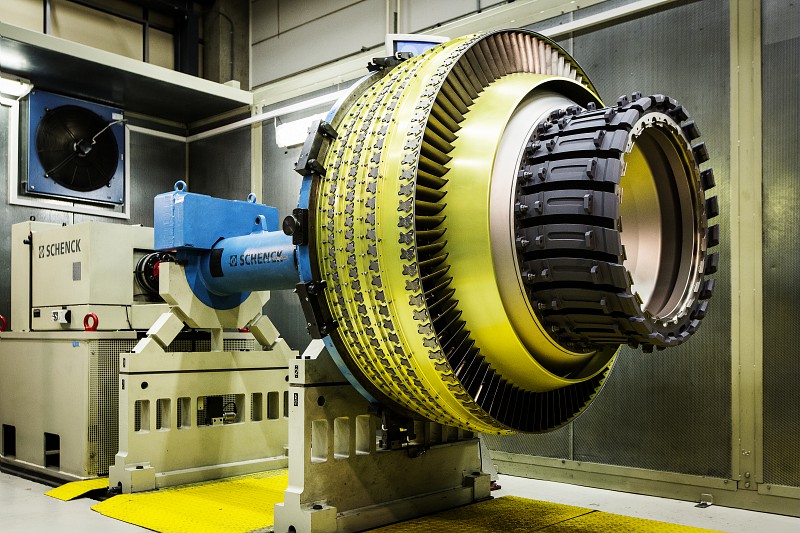

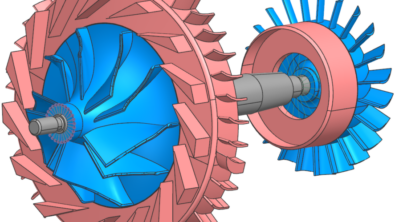

The structural dynamics study of complex turbomachines, like jet engines or gas turbines, is a challenge today. The rotating parts of turbomachines are usually designed with different stages on which blades are mounted to ensure the energy transfer towards or from the fluid. Modeling such components using full 3D CAE models implies a too high number of degrees of freedom which becomes computationally prohibitive. Therefore to reduce the problem, the dynamic behavior is often simulated stage by stage. However, engineers have noticed that the interstage coupling can significantly affect the dynamics of the multi-stage assembly, something which cannot be accounted for with this piecemeal approach.

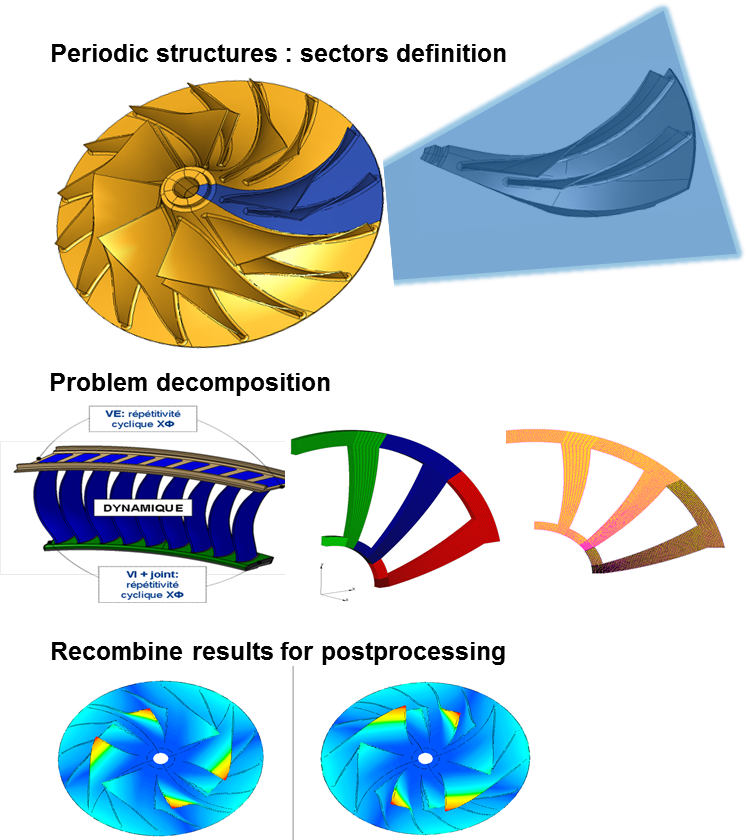

As I discussed a few weeks ago in my two-part article on acoustics simulation, again we are called upon here to simulate in an intelligent way, and in this case, the product shows us the way. Inherent to rotating machinery is symmetry and in these periodic structures, symmetry exists over angular sectors. Sectors consist of a few blades which can be identified on the structure at each stage and can be periodically reproduced around the turbomachine rotation axis. Taking benefit of this cyclic symmetry allows the user to model and analyze a smaller model and to recombine afterward the 3D CAE results on the complete structure to suitably interpret the engineering results.

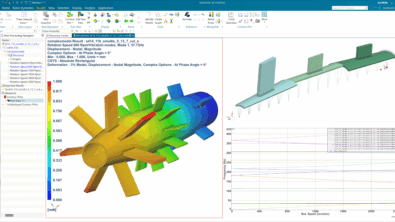

The problem decomposition is done by selecting a periodic structure that is then calculated into detail. The results are post processed to get the recombined results for the entire structure. This type of symmetry is referred to as “multi-stage cyclic symmetry”. Multi-stage cyclic symmetry has been used for several years for the modal and dynamic response analyses of turbo-machineries in the use of detailed models at limited cost. With this method, available in Simcenter 3D Samcef Rotors, part of the Simcenter portfolio, each stage of the machine is cyclically modeled and inter-stage coupling combines the different stages. The coupling is either mesh compatible or not. Though it is an approximate method, it provides high-quality results in the low-frequency range. For higher frequencies, approximations may occur and they are mainly detected at the inter-stage junctions.

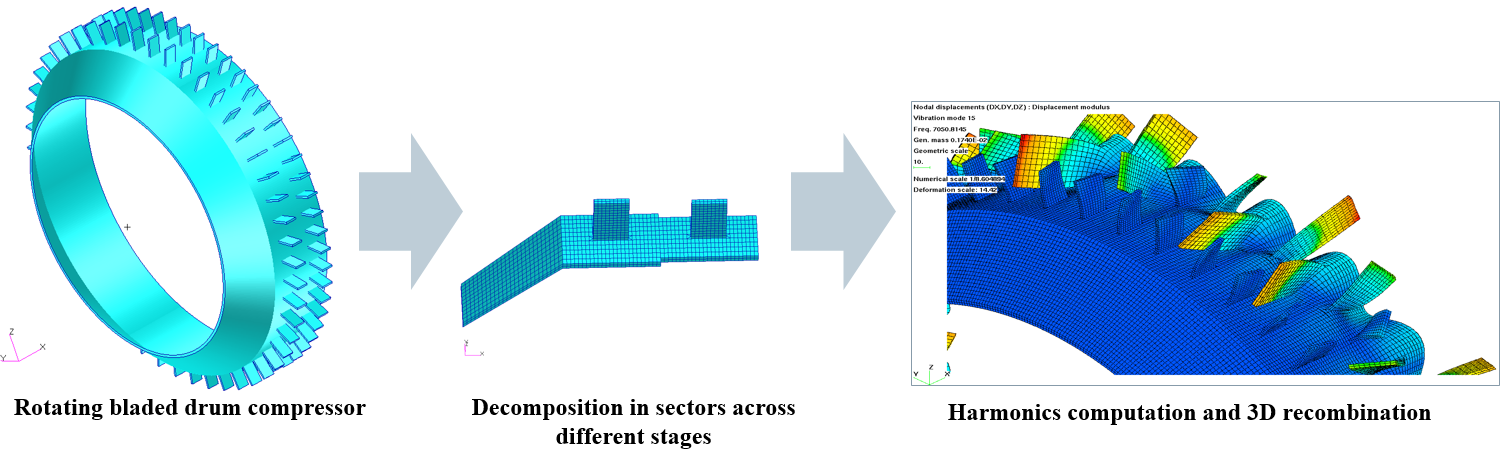

The multi-stage cyclic symmetry method relies on harmonic decomposition, where the response is represented by a limited number of functions. In such a decomposition, missing harmonics can be detected for some stages. The method in LMS Samtech Samcef Rotors has therefore been enriched in order to automatically add basic fundamental harmonics. The different cyclic fields are then coupled at the inter-stage junctions. Depending on the problem to solve, a tangential, radial or axial decomposition can be done.

Within the context of the ICOGEN (Integration of COmposites for Greener Engine) project, this methodology was used to predict the modal and dynamic response analyses of a rotating bladed drum compressor in collaboration with Safran Aero Boosters.

The model had the particularity that different meshes were taken into account for blades in each sub-sector. The different stages were weighted based on energy balance. Results obtained with different numbers of basic cyclic fields were compared. Modes were recombined and paired for post-processing thanks to the Modal Assurance Criterion (MAC) criteria. The effect of the locations of the inter-stage junctions was also analyzed and compared.

Thus taking the multi-stage cyclic symmetry method made it possible to study the dynamic behavior of multi-stage turbomachinery, achieving a reliable level of accuracy, while taking benefit from the cyclic symmetry across the different stages of the turbomachine.

Comments

Comments are closed.