Sopemea boosts seismic test efficiency: 90% faster setup, 60% shorter runs

🌍 Preparing for the unpredictable

Earthquakes are sudden, powerful, and complex. They unleash multi-directional forces that can severely challenge the structural integrity of even the most carefully engineered systems. For industries that rely on critical infrastructure ensuring that equipment can survive seismic events is not just a technical requirement, but a public safety imperative.

Yet, replicating the chaotic nature of an earthquake in a controlled lab environment has long been a challenge. Traditional testing methods often fall short, leaving a gap between simulated conditions and real-world performance.

⚙️ The testing gap: limitations of traditional seismic testing methods

Historically, seismic qualification relied heavily on single-axis or biaxial shaker tables. These setups excite equipment in one direction at a time, typically in perpendicular sequences. While useful for basic vibration testing, they don’t reflect the simultaneous, multi-directional stresses that occur during an actual earthquake.

This limitation led to two major consequences:

- Undertesting: Equipment might pass lab tests but fail in real-world seismic conditions.

- Overengineering: To compensate for testing limitations, manufacturers often added extra materials or reinforcements, increasing both cost and weight unnecessarily.

For companies like Sopemea, which specialize in testing and qualification, this gap presented a clear opportunity for improvement.

🎯 Sopemea’s objective: realism meets efficiency

Sopemea set out to enhance both the accuracy and efficiency of seismic testing. Their goal was to move beyond sequential testing and adopt a multi-axis approach that could simulate real earthquake conditions more faithfully.

At the same time, they wanted to reduce the time and complexity involved in setting up and running tests. In high-stakes industries, time saved in testing can translate to faster product development, reduced costs, and quicker time-to-market: all without compromising safety.

🧰 The Simcenter solution: unified control and multi-axis capability

To achieve this, Sopemea partnered with Siemens and adopted Simcenter SCADAS and Simcenter Testlab, a comprehensive solution for dynamic environmental testing. By 2019, Sopemea was operating 30 different control systems across its facilities. Consolidating these into a single, unified platform was a strategic move that laid the foundation for greater efficiency.

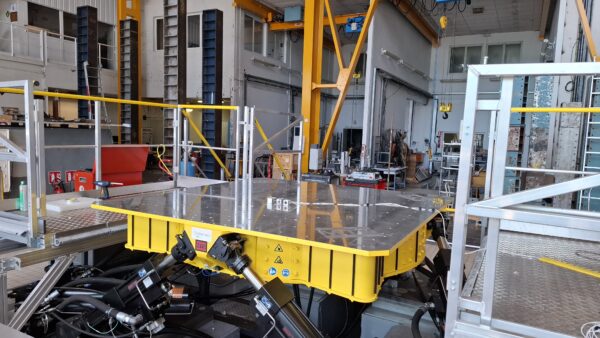

They also invested in a triaxial shaking table, a test bench commonly used in the automotive industry. Sopemea adapted it for seismic testing, enabling them to simulate complex, multi-directional forces in a single test run.

Lisbeth Marty, Mechanical Testing Engineer at Sopemea, explained:

“This type of test bench is widely used in the automotive industry, but we wanted to adapt it for seismic testing to verify that energy equipment is sturdy enough to withstand earthquakes.”

🤝 Collaboration and methodology: reinventing the process

The collaboration between Sopemea and Simcenter engineers went beyond hardware. Together, they redefined the methodology for deriving shocks from multiple Shock Response Spectra (SRS) for earthquake qualification to accurately replicate seismic events.

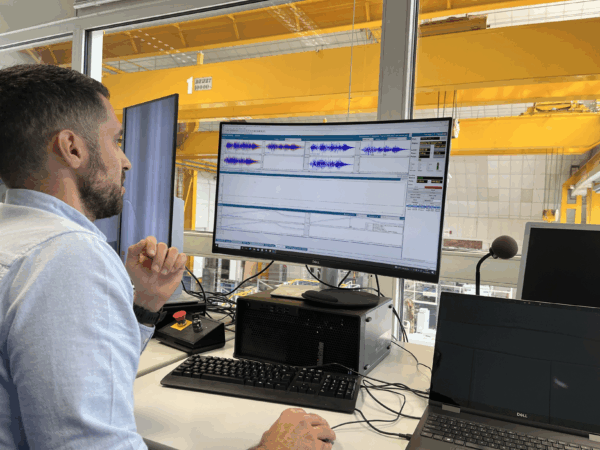

This led to the development of a Multiple-Input Multiple-Output (MIMO) control algorithm that could drive multi-axis rigs with high precision. The system guides users from initial setup through to final reporting, ensuring consistency and accuracy throughout the testing process.

📈 Efficiency gains: time saved, accuracy improved

The results of this collaboration were substantial:

- 💡 90% Faster Setup: Test setup time dropped from several hours to just 20 minutes, allowing engineers to focus more on analysis and less on configuration.

- ⏳ 60% Shorter Test Runs: Execution time was significantly reduced, enabling more tests to be completed in less time.

- 🔧 Streamlined Control: Engineers can now define an “under-testing avoidance factor,” ensuring that the appropriate level of stress is applied without overcompensating.

- 📊 Collaborative Reporting: Simcenter Testlab’s “active picture” feature allows customers to interact with test data and adjust parameters without needing a license. This makes the review process more transparent and collaborative.

Xavier Caron, Test Engineer at Sopemea, shared:

Simcenter Testlab is very intuitive. One test that used to take half a day to set up now takes just 20 minutes.

🛠️ Strong technical support: a trusted partnership

Lisbeth Marty emphasized the value of Siemens’ technical support:

“We’re really happy with our collaboration with Siemens and the technical support from them in developing the MIMO solution. They came to our lab several times: first, we explained how we run seismic tests, and then Siemens showed us the first implementation and tested it in lab conditions. Their technical expertise was superb, and they were very professional and easy to work with.”

This close collaboration ensured that the solution was not only technically sound but also tailored to Sopemea’s specific needs.

🛤️ Looking ahead: shaping the future of seismic testing

Sopemea’s work is helping to shape future standards for seismic qualification especially in Europe. By improving both the realism and efficiency of testing, they are paving the way for safer, more cost-effective product development across multiple industries.

Umberto Musella, Simcenter’s product manager for shock and vibration products, highlighted the broader impact:

“Sopemea is doing important work in investigating and establishing the standards for multi-axis testing. This will be very significant for the European market in the coming years.”