How to use digital tools to meet EEXI targets across your fleet

In June 2021, the International Maritime Organization (IMO) adopted amendments to MARPOL Annex VI that introduced an Energy Efficiency Index (EEXI) for existing ships. The EEXI is applied to almost all oceangoing cargo and passenger ships above 400 gross tonnage.

In contrast to the Energy Efficiency Design Index (EEDI) that regulates emissions for new-build ships, the EEXI applies to existing vessels. This regulation mandates that all ships calculate their EEXI, which measures CO2 emissions per transport work, and get a rating based on their energy efficiency (A, B, C, D, E). Ships are expected to maintain a C rating or above. Vessels that receive a D rating for three years in a row or a single E rating are required to submit an action plan to bring the ship in line with standards.

Applying EEXI to your existing fleet involves two stages: first, assess each ship’s current CO2 emissions, and second, implement technical solutions to reduce the emissions and meet the required EEXI target. But deciding which technical solutions to implement on each ship is not straightforward. How can you compare the efficiency gains of different options while also considering the associated costs and any impact on vessel performance?

Shipyards and naval architects have been asking – and answering – similar questions for years as part of the process of designing and building new ships. Through a combination of computer simulation and model testing, they assess many alternative designs, including hull form, propulsion, energy-saving devices, etc., so that every new-build ship performs as required during the final sea trial and now also meets the relevant EEDI requirements. But implementing changes to your existing fleet to meet EEXI is more challenging. The ships are already in operation, so creating a physical model of the existing hull, adding modifications and running towing-tank tests is expensive and time-consuming. Model testing can only be used for a small range of design changes, so the data is severely limited. This approach will not help if you want to investigate novel solutions, such as wind-assisted power or keeping the existing arrangement but running at reduced engine power.

Simulation is the key to reaching EEXI targets

The solution to finding the best efficiency improvements to meet EEXI targets is to go digital. The Siemens Xcelerator portfolio contains a range of simulation tools that can be used to create a digital twin of your existing ship, assess its performance and virtually test multiple alternative efficiency solutions. This gives you the ability to explore a wide range of options and assess both their efficiency gains and potential cost implications before any retrofit or sea trial takes place. Siemens Xcelerator includes tools for CAD, computational fluid dynamics (CFD), stress analysis, system simulation and design exploration and optimization. These tools are designed to work together and form an open environment to be linked to existing data sets for analysis tools. With a digital approach to efficiency assessment, you can:

- Use a digital twin

- Test multiple contributing factors to any vessel’s energy demands in one virtual environment

- Investigate every aspect of ship performance under actual operating conditions

Simulation-driven efficiency assessment

A digital twin is a virtual representation of the physical ship used to predict performance and investigate the impact of changes when in operations during design. This virtual approach improves the effectiveness of the search for the best efficiency solutions and speeds up the design and retrofit process. Once the ship is in operation, the digital twin also benefits from the data feedback thread, such as from sea trials and mission profiles.

The digital twin enables a simulation-driven approach to ship design and performance analysis. This is based on a central ship model, which contains all available data on ship geometry, layout and performance – a single source of truth. For any suggested configuration change the required information for the current ship is drawn from the central model. With a simulation-driven design approach, you can simulate and analyze the performance and explore alternatives to search for the optimal design. The data from this investigation is then fed back into the central model, available to all stakeholders. The central model is updated to include the new information when a final design change is agreed upon. This makes the central model the heart of the digital twin for a ship throughout its lifecycle.

This simulation-driven approach also makes it quick and easy to identify the best efficiency solution for ships in operation and tailor designs to individual ships. Automated optimization software can search for the best configuration within specified constraints: With this approach you allow computers to do the heavy lifting, with experts and stakeholders then evaluating and selecting from suggested best designs. For example, you can assess hundreds of alternatives to find the one that both minimizes capital expenditure (CAPEX) during build or retrofit and meets your efficiency requirements while keeping operational expenditure (OPEX) at acceptable levels.

Virtually assess a wide range of solutions with simulation software

In recent years the marine industry has seen an explosion of possible efficiency improvement options and ideas, including hull-targeted solutions such as energy-saving devices or air lubrication, engine adaptations such as scrubbers, and alternative fuels or downrating for reduced power. Using simulation software, all of these can be tested digitally before implementation to find the best options (or combination of options) for your ship. For example:

- Using simulation, energy-saving devices and rudder systems can be tailored to individual ships. Becker Marine Systems uses this approach for every installation of their Becker-Mewis ducts, which provide up to 6% annual fuel savings.

- Simulation is a key tool in the development of new efficiency solutions, such as wind-assisted propulsion. In a recent study, Cape Horn Engineering used simulation software to compare the delivered propeller power (and thus fuel savings) for the same ship with either solid wings or Flettner rotors. They found a 24% reduction in required power under given conditions if wing sails were used.

- With virtual testing it is possible to find scrubber configurations that deliver the highest scrubbing performance at the lowest pressure-drop and lowest equipment footprint to minimize its impact on operational performance.

- Companies are using simulation for combustion engine analyses. When designing its Wärtsilä 31 diesel engine, Wärtsilä used CFD software from Simcenter, part of the Siemens Xcelerator portfolio, to produce what was named the most efficient diesel engine by Guinness World Records.

Predict performance under actual operating conditions with simulation

Ship performance contracts are typically defined based on design speed and draft. This is assessed during sea trials before final acceptance into service. But in reality, every ship sails under a range of operating conditions. Optimizing performance for a single point in calm conditions does not guarantee safe or efficient performance across all weather conditions and complete mission profiles. Shipyards and owners are starting to recognize this and change their tendering requirements. For example, NYK Line and Japan United Corporation (JMU) introduced a contract guaranteeing propulsion performance in actual sea conditions, verified using data collected during ship operation. Here again, a digital approach to performance prediction can give you full confidence before launch. Using simulation software you can perform hydrodynamic simulations of your full-size ship under any combination of wind and wave conditions. With the included automated design exploration tools, you can quickly set up and run sweeps over different speeds or wave conditions. The whole investigation can run in a matter of hours on a cloud computing platform, giving you all the data you need to make fully informed decisions.

It is also easy to include the propulsion system in the simulation and investigate ship power consumption. In a webinar, we presented an example of predicting ship minimum power requirements for safe operation in head and beam seas, as per the IMO process for obtaining EEDI certification.

Optimizing ship operations with a simulation-driven approach

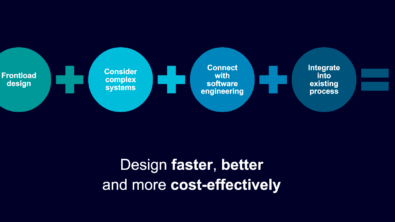

Many companies already use this simulation-driven approach during the early design stage for new ships. But with the new EEXI regulations, the same tools can now add huge value during ship operations. In fact, the IMO approved simulation as an accepted method for the EEXI calculation process. As part of resolution MEPC.334 (76), the committee agreed that ship speed-power relations can be calculated using CFD with no requirement for model tests. By applying simulation-driven investigations today to your EEXI compliance plans, you can have confidence in your planned solutions whether you plan on retrofitting or making engine modifications and guarantee your fleet will meet all efficiency requirements, both now and in the future.

Ready to learn more about adopting an integrated approach to ship design and engineering? Click here to find more information and resources on digitalizing your marine enterprise.

A version of this article by Dejan Radosavljevic, former director of marine for Siemens Digital Industries Software, first appeared in the Clean Shipping International magazine.