InfinitForm chooses Parasolid to deploy AI across design-to-manufacturing workflows

AI design and engineering assistants are rapidly becoming a key area of innovation, transforming how products are conceptualized and developed across various industries.

Traditionally, design optimization relied on an expensive iterative trial-and-error process, constrained by the designers’ domain expertise and bandwidth.

AI design and engineering assistants automate the optimization process, exploring a wider range of design alternatives that meet specified constraints and performance goals, significantly accelerating optimization cycles.

To capitalize on the potential of this technology, it is imperative to efficiently integrate it into existing product life-cycle ecosystems, maintaining data compatibility and supporting various downstream engineering and manufacturing processes.

When design (CAD), simulation (CAE) and manufacturing (CAM) occur in disconnected software environments, engineers are often forced to “go back to start” when manufacturability issues are progressively identified at each stage.

A lack of design-for-manufacturing (DFM) expertise and slow feedback loops from production can further increase costs and time-to-market and ultimately hold back product innovation.

Built upon the extensive expertise in AI-driven design, structural optimization and manufacturing of its founders, InfinitForm set out to eliminate these critical cross-system bottlenecks, seamlessly deploying an AI engineering intelligence layer that serves as an assistant in the design to manufacturing processes.

Technical challenges

AI-generated designs often prioritize performance optimization, making them easily compatible with additive manufacturing techniques, but complicated to produce with cost-effective mass-manufacturing systems such as CNC machining, die casting and injection molding.

InfinitForm’s objective was to provide a robust engineering solution that incorporates manufacturability analysis from the outset, allowing the rapid development of models optimized for traditional manufacturing systems, while still delivering the design’s intention and functional performance.

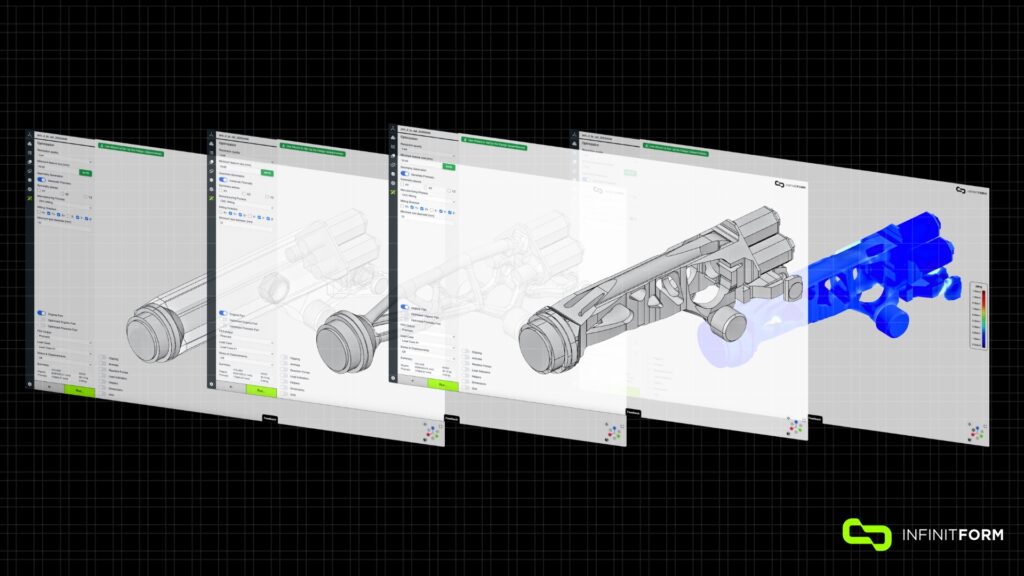

Generative AI outputs typically depend on facet representation, with precision limited by the mesh’s resolution. Manufacturing-ready designs, however, require the exact boundary representation (B-rep) used by most CAD systems as their data model. This allows engineers to accurately edit parametric designs and easily export them to downstream mass-manufacturing software.

Generating prismatic models with manufacturing constraints built-in and providing advanced, reliable direct modeling capabilities on accurate geometry were therefore essential requirements for the success of InfinitForm’s solution. This unique prismatic design intelligence sets InfinitForm apart, delivering optimized geometries that are inherently manufacturable across traditional and advanced production methods, eliminating the gap that plagues other generative design tools.

Recognizing the huge investment required to develop these capabilities in-house, the company strategically evaluated geometric kernels available on the market.

After a thorough assessment, Infinitform selected Parasolid, the leading 3D geometric kernel from Siemens.

Keys to success

Parasolid, the industry-standard 3D geometry kernel, could provide highly advanced modeling functionalities, unparalleled performance and stability, and interoperability due to its widespread adoption among the main CAD systems in the market.

The integration of Parasolid allowed InfinitForm to focus on developing innovative aspects of their AI design assistant platform with integrated manufacturability analysis, while the kernel reliably handled the complexity of geometry modeling.

In addition to user-defined constraints and parameters, InfinitForm’s AI design assistant incorporates comprehensive manufacturability assessment, allowing designers to seamlessly explore multiple manufacturing method alternatives during the optimization process. The ability to incorporate manufacturing specifications and cost considerations early in the design process guarantees the viability and producibility of output designs, reducing downstream iterations.

Regardless of the complexity of the AI-driven design generation and simulation, InfinitForm can guarantee excellent performance of the optimization process, enabling informed design decisions based on manufacturability.

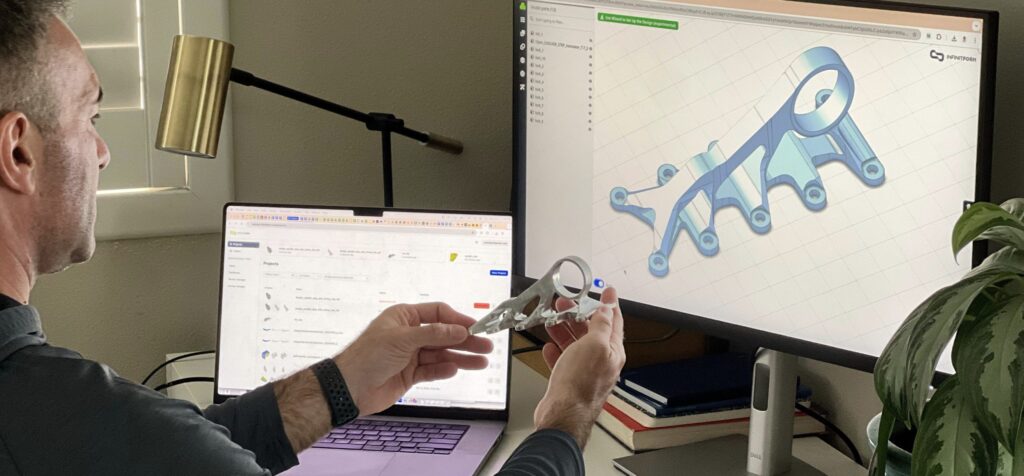

InfinitForm’s platform supplements, automates and enhances customers’ existing workflows. It provides a lightweight solution to import design concepts and translate them into accurate, manufacturing-ready models thanks to Parasolid’s robust geometry handling.

The platform also provides collaboration tools within and outside organizations, ensuring that when production is outsourced, the same best-in-class quality of manufacturable design data can be shared with suppliers. Seamless collaboration across historically siloed functional teams, with manufacturability considerations integrated throughout, has led to design cycles improved by up to 70%, with the potential of bringing new products to market faster and cheaper.

Leveraging Parasolid, InfinitForm can generate prismatic models with embedded manufacturability constraints that are fully editable in any CAD system.

Michael Bogomolny, CEO and Founder of InfinitForm

Partnership with Siemens

Throughout the integration of Parasolid, the collaboration with the Siemens technical team was essential to ensure that the best-in-class functionalities of the kernel could be optimally implemented for manufacturing-centric design workflows. Parasolid offers extensive documentation and support for all main operating systems and architectures available, making it a truly plug-and-play component.

Thanks to the partnership with Siemens, InfinitForm brings order to chaos, generating and simulating production-ready, optimized designs with built-in manufacturability assessment for most modes of manufacturing.

InfinitForm creates synergy throughout CAD, CAE, and CAM systems, while ensuring designs can be efficiently produced at scale.

Learn more

If you’d like to know more about Infinitform, visit https://infinitform.com/, check the LinkedIn page at https://www.linkedin.com/company/infinitform/ and their Youtube channel at https://www.youtube.com/@InfinitForm.

Stay up-to-date by following InfinitForm on Instagram, Facebook and X.

To know more about Parasolid, visit the product page Parasolid 3D Geometric Modeling | Siemens Software or request a free 60 days trial at Request your free 60-day evaluation of Parasolid | Siemens Software.

Parasolid is part of the Siemens PLM Components portfolio, a set of advanced, industry-proven Software Development Kits integrated by 3D applications in product design, simulation and manufacturing. To know more, visit PLM Components | Siemens Software.

If you are developing next-generation software for 3D product design, simulation or manufacturing, join us in Cambridge, UK, on April 28-29, 2026, for the fourth PLM Components Innovation Conference. This is a unique opportunity to understand the value of PLM Components and joining Siemens’ open software vendor ecosystem.

To know more and register for the free event, visit PLM Components Innovation Conference 2026 | Siemens Software.