Designing more beautiful products just got easier

Humans appreciate beauty. This is true in all facets of life, including architecture, fashion, landscapes, consumer products, and, of course, other people. It’s an accepted fact that ‘good looking’ people receive favorable treatment as they go through life. Products with high visual appeal typically command a premium price compared to less attractive products. Certain buildings are considered more beautiful than others.

Take a moment and think about what makes something beautiful. Of course, beauty is a personal topic and ultimately is in the “eye of the beholder”, but what is it about certain objects that makes them considered more beautiful than others? Here are a few attributes that contribute significantly to an object’s beauty.

Color

Color has a profound effect on our moods, perceptions and behavior. It can have a significant effect on our minds and even our bodies. For example, colors in the red spectrum are typically used to foster emotions like love, passion and anger; blue connotes calm and cool while green is considered natural, soothing and refreshing. Certain color combinations are also more pleasing than others. That’s why PowerPoint templates include a recommended color palette, so that the colors complement each other and enhance the presentation. Research into buying behavior shows that the colors used in a website are just as important as its performance and user interaction model. In other words, the same website with the wrong colors will result in fewer sales.

Proportion

Over 2000 years ago, mathematicians studying regular pentagrams, pentagons and certain rectangles found that the length of the sides was in a specific ratio. Euclid called this the “Golden Ratio” (approximately 1.618). It’s also known as “phi” and it inspired (and still inspires) artists, architects and designers because objects that incorporate this ratio into their dimensions are aesthetically pleasing. The Golden Ratio (and the related Fibonacci sequence) can be found in financial price patterns, architecture, literature, music and art. It’s also found in nature and human faces.

Shape

The shape of an object contributes greatly to its beauty. Most people are drawn to simple, elegant shapes. Objects that are widely considered beautiful include the Juicy Salif lemon squeezer, a classic Coke bottle, Isamu Noguchi coffee tables, classic Jaguars and Ferraris and Arne Jacobsen’s egg chair. Of course, this is only a tiny fraction of beautifully shaped products, examples of which are prolific throughout contemporary design in architecture, automotive, marine and consumer products.

Beautiful Products

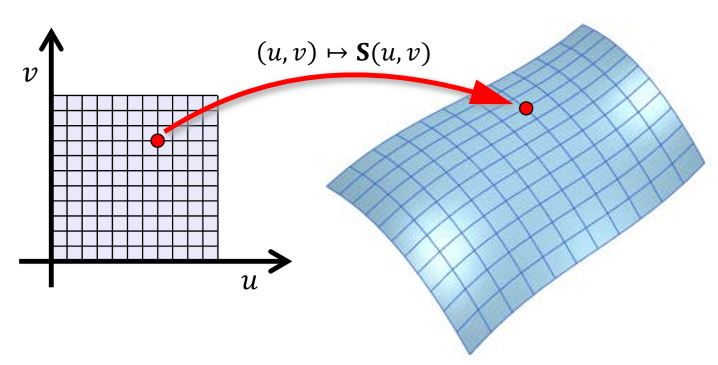

Mathematically, a traditional CAD system would represent these objects (and any object) as Boundary Representations (B-rep). A B-rep 3D model is a collection of connected curves and curved surfaces forming a closed volume, and is the basis for all modern 3D CAD systems. There are several types of surfaces that can be used to create 3D models including planes, cylinders, cones, spheres, NURBS, etc. These surfaces are often called ‘precise’ surfaces because their contours are represented by precise mathematical equations. The equations are “parametric” ones, which means that they deform a basic rectangular shape to form the surface. As a result, all the surfaces in contemporary CAD systems look like stretched/warped rectangles.

Parametric Surface

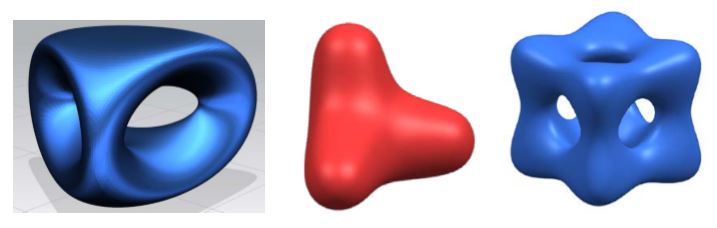

Parametric surfaces provide an extremely powerful way to model many 3D shapes, but they don’t work very well for shapes that are highly convoluted or pierced by holes. But there is another class of surfaces, called “implicit” surfaces that are more general than parametric surfaces and can easily model shapes like the ones below:

Implicit Surfaces

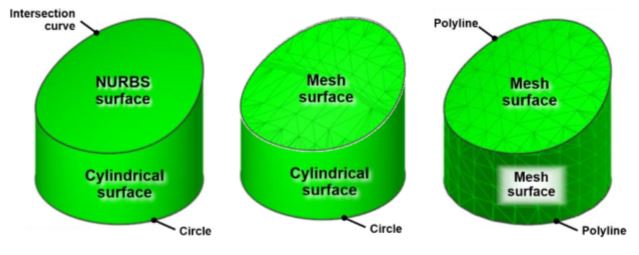

You can’t produce shapes like these by warping a rectangle, so they are difficult to model using traditional parametric surfaces. In order to overcome this limitation Parasolid added support for mesh surfaces that makes it possible to model implicit surfaces (and any other kind of surface). This new surface type is basically a connected collection of triangular facets and is used along with a new polyline curve type to model any 3D shape imaginable.

Different Surface Types

It’s important to understand that many traditional CAD systems have worked with precise (B-rep) surfaces and could not create or edit faceted surfaces. Support for faceted models was limited to importing them as reference geometry or converting them into B-rep models which could be time-consuming and prone to error. Today’s CAD systems can also convert precise models to facets and write them out for another application (typically additive manufacturing).

The Parasolid breakthrough is that all modeling operations now work on both precise and mesh (faceted) surfaces. It also works on models with both precise and meshed surfaces. This means that a full range of CAD operations is available to the designer for any type of model. This new Parasolid solution is called Convergent ModelingTM technology because it brings traditional CAD modeling capabilities to both precise and meshed models.

This is especially important from a productivity perspective for reverse engineering workflows. The starting point for these workflows is a scanned (faceted) model of an existing object. The goal is to create a new design based on the original, but because traditional CAD systems can’t edit meshed models, the designer has to spend a large amount of time and effort recreating the meshed model as a precise model. This step can be extremely tedious, especially for complex parts, and doesn’t contribute to product improvement or innovation. With Convergent Modeling technology the designer is able to work directly with facetted models. His/her time can be spent improving the design rather than recreating surfaces. Productivity, innovation and morale are greatly improved!

Increased design productivity is an important benefit of Convergent Modeling, but, as previously discussed, this new technology also enables the design of more beautiful products by including shapes described by implicit surfaces.

Implicit surfaces have engineering benefits in addition to their aesthetic value. Certain surfaces that have simple implicit equations are also “minimal” surfaces. They are essentially the shape a soap film would make when filling a boundary; 3D objects with minimal surfaces have the minimum possible surface area and lowest weight for any given material.

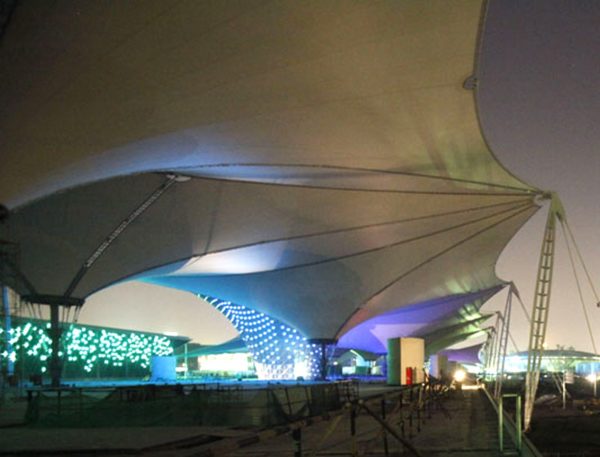

Minimal surfaces have application in architecture (especially tensile roof structures), lattice support structures for additive manufacturing, molecular engineering and materials science. Scientists are still exploring how to take advantage of their unique characteristics.

Tensile Roof Example

While science investigates potential applications for implicit surfaces, artists and designers are finding inspiration in these beautiful shapes. Sculptors like Robert Engman, Robert Longhurst and Charles O. Perry created works of art based on minimal surfaces while L.S. Watson created an entire line of jewelry called ‘Minimal Surfaces’ that is now commercially available. Dominik Raskin designed a line of furniture that includes coffee tables, stools and lamps based on minimal surfaces. These are just a few examples of how products are becoming more beautiful using implicit surfaces. The sculptures and jewelry were probably designed using physical models made out of clay and wax, respectively. These types of tools and processes are labor intensive, and only suitable for low volume products like art and conceptual work.

Parasolid Convergent Modeling makes it easy to incorporate implicit surfaces into product designs inside a production CAD system which can be used to drive mass production. It does this by giving existing CAD systems based on Parasolid the ability to create and modify any type of surface, including implicit surfaces. The CAD user experience and operations are the same for all surfaces, nothing has changed but the system’s ability to model previously impossible shapes. Designers are no longer limited by their CAD tools and now have the freedom to make their products more beautiful than ever before.

More information about Convergent Modeling is available on the Siemens Digital Industries Software web site.

Authors: John Whetstone, George Allen and Hiren Dedhia