Empowering PCB Design with Advanced Technologies: Exploring the Benefits of a Cloud-based DFM Solution.

In today’s rapidly evolving technological landscape, the electronics industry demands innovative solutions that streamline the Printed Circuit Board (PCB) design and manufacturing process. One such solution that has gained significant traction is a cloud-based PCB Design for Manufacturability (DFM) platform. By leveraging advanced technologies, optimizing the supply chain, and embracing the industry 4.0 paradigm, cloud-based DFM solutions have emerged as a game-changer. This article explores the advantages of a cloud-based PCB CAM and DFM Software-as-a-Service (SaaS) solution and highlights how it enhances DFM analysis to propel PCB design forward.

The advent of cloud computing has revolutionized various industries, and PCB design is no exception. A cloud-based PCB CAM and DFM SaaS service offers numerous benefits, including accessibility, scalability, and collaboration. Designers can now access the platform from anywhere, at any time, using any device with an internet connection. This enables seamless collaboration between teams across different geographies, accelerating the design process and eliminating communication gaps. Additionally, the scalability of cloud solutions ensures that designers can efficiently manage growing design complexities while maintaining optimal performance.

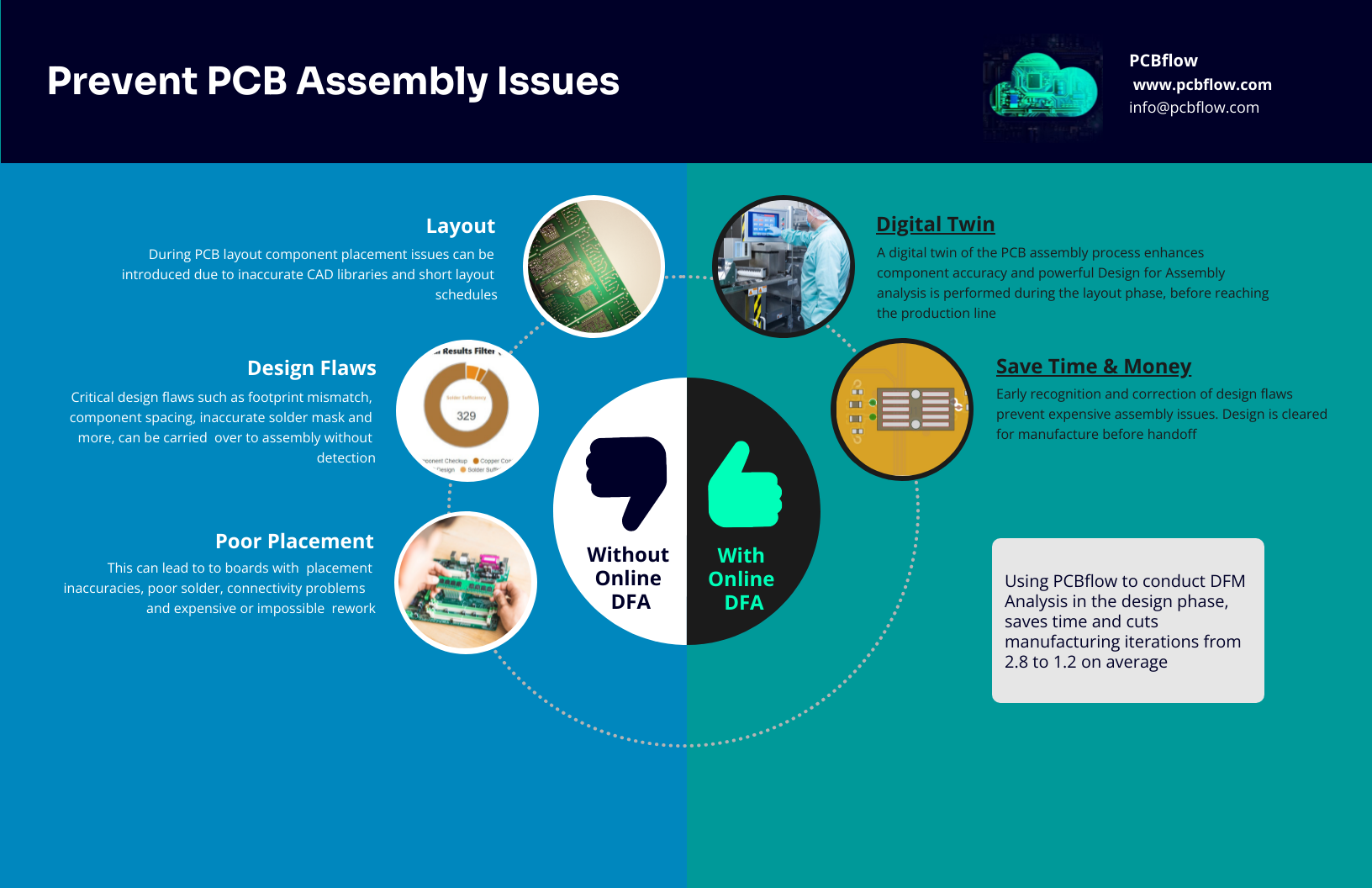

DFM analysis plays a critical role in ensuring that a PCB design is manufacturable, reliable, and cost-effective. By analyzing design data and leveraging a vast database of manufacturing rules and guidelines, these solutions can identify potential manufacturing issues early in the design cycle. This enables designers to make informed decisions, reducing costly design iterations and improving overall time-to-market. With real-time feedback and comprehensive DFM reports on design rule violations, such as clearance issues, impedance mismatches, and solder mask conflicts designers can address design constraints and optimize their PCB layout for improved manufacturability.

Furthermore, by leveraging cloud computing resources, these tools can perform complex DFM checks more efficiently, allowing designers to focus on innovation and design optimization.

By adopting a cloud-based PCB CAM and DFM SaaS service, designers can leverage the power of the cloud, optimize their supply chain, and embrace Industry 4.0 principles. As PCB design tools continue to evolve and incorporate DFM capabilities, the industry moves closer to achieving more efficient and manufacturable designs, driving innovation forward in the electronics sector.