PCB 102: How PCB Design Requirements Affect Fabrication

Printed Circuit Boards (PCBs) are an essential component of modern electronics, and their design and fabrication are critical to the success of any electronic device. PCBs are used in a wide range of applications, from consumer electronics to aerospace and defense systems. The design and fabrication of PCBs are complex processes that require careful attention to detail and adherence to specific design requirements. In this blog post, we will explore how PCB design requirements affect fabrication, and how the finished product can meet the intended quality and reliability requirements.

Multilayer PCB Fabrication Process

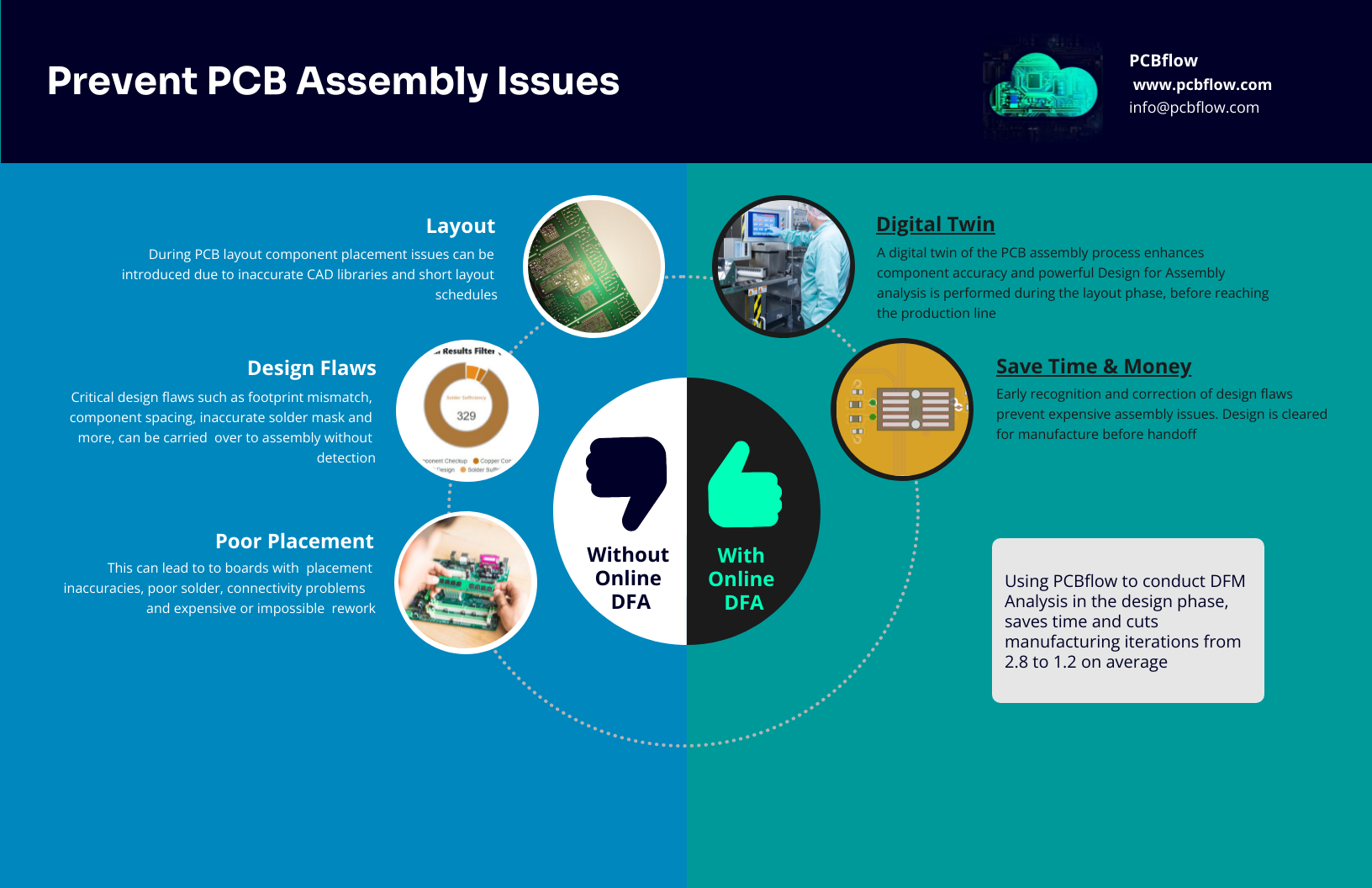

The multilayer PCB fabrication process involves several steps, each of which is critical to the quality and reliability of the finished product. The process starts with the design of the PCB, which includes the placement of components and the routing of traces. The design must meet specific requirements to ensure that the PCB can be fabricated correctly and will meet the intended quality and reliability requirements.

The design is then transferred to the fabrication process, which involves several steps, including drilling, plating, etching, and lamination. Each of these steps is critical to the quality and reliability of the finished product, and any errors or defects can result in a faulty PCB.

Design Requirements: The Key to Success

Design requirements form the backbone of a successful fabrication process. The designer must adhere to specific guidelines to ensure that the PCB can be fabricated correctly and will meet the intended quality and reliability requirements. Understanding their impact on fabrication and yield rates is crucial to achieving exceptional results.

Process Controls for Optimal Results

Process controls are adopted by the fabricator to ensure maximum yields and quality are maintained during each step of fabrication. These controls include the use of specific materials, equipment, and techniques to ensure that the PCB is fabricated correctly and meets the intended quality and reliability requirements.

Variables Available to the Designer

The designer has several variables available to them, including solder mask, surface finish, materials selection, copper weights, feature size, and more. Each of these variables can impact the quality and reliability of the finished product, and the designer must carefully consider each one to ensure that the PCB meets the intended requirements.

In Conclusion

In conclusion, the design and fabrication of PCBs are complex processes that require careful attention to detail and adherence to specific design requirements. The designer must carefully consider each variable and weigh the pros and cons to ensure that the PCB meets the intended quality and reliability requirements. The process controls adopted by the fabricator are critical to ensuring maximum yields and quality are maintained during each step of fabrication. By understanding how PCB design requirements affect fabrication, designers can create high-quality and reliable PCBs that meet the needs of their intended applications.