Limitless perspectives, one big idea: Scaling the “Smart” of the Smart Factory

Make your factory smart through effective value chain transformation

In the world of manufacturing, the race is on to deliver smarter, faster and cost-effective solutions to clients and their customers. Therefore, a Smart Factory has to be progressive, not binary — with the potential of becoming increasingly smarter and more agile to deliver greater value to the business continuously.

It is also important to recognize the existing assets that manufacturers have already invested in. As a result, it is possible to leverage and enhance their current technology infrastructure to help evolve their factories into the future and position them to capitalize on emerging opportunities.

The manufacturing vision

Manufactures need access to the most advanced technology to deliver industry-specific values such as:

- Identifying performance gains

- Mapping out new business capabilities

- Ensuring actionable results

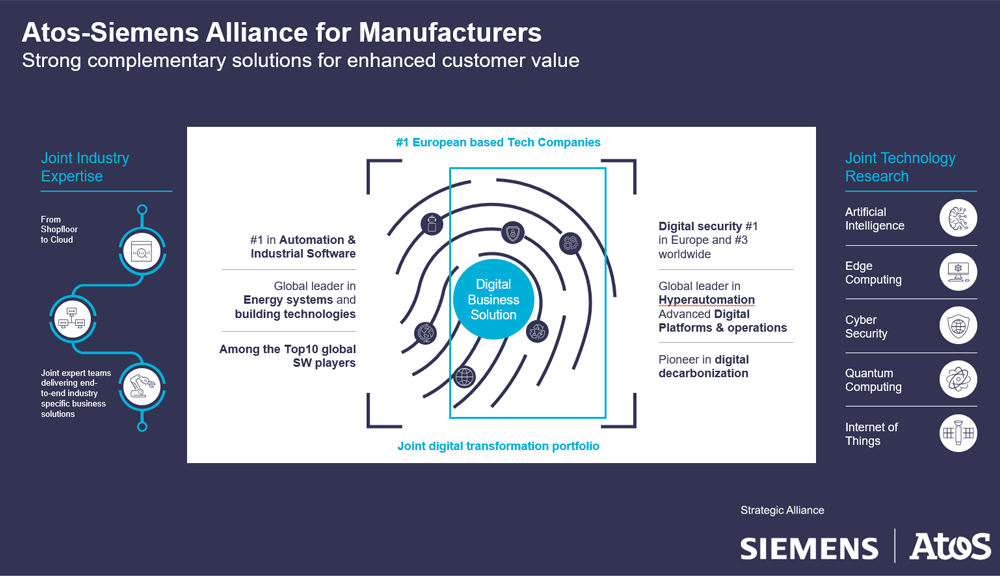

In response to this shifting landscape, Atos and Siemens have leveraged their long-standing, powerful strategic alliance to launch the very first specific global manufacturing initiative to accelerate Smart Factory Programs. This joint approach opens the way for manufacturers to digitally transform, stay ahead of the competition, and drive meaningful business outcomes.

Our vision for manufacturers focuses on deploying innovative, sustainable, and decarbonized services, technologies and solutions for clients worldwide. By building agile and responsive ecosystems to stay ahead of the competition, enterprises can manufacture a new future by leveraging success from the past. Our collaboration methods harness and leverage data to monitor, interpret and respond in real-time to both internal operations and across extended global supply chains.

Manufacturers ready to take the leap and digitally transform their organizations can gain significant rewards.

Accelerating in the right direction

43 percent of businesses are encountering so many roadblocks, they’re now reporting digital transformation fatigue.

Annual Manufacturing Report 2020

The Atos and Siemens Alliance for Manufacturing intelligently scales selective capabilities critical for success, including the combination of both the technology and business functions. Traditional roadblocks such as being unfamiliar with new systems, limited skill sets and financial challenges are addressed and imaginatively resolved with a joint manufacturing approach that blends Atos Manufacturing’s Smart Factory solutions and the Siemens Xcelerator portfolio.

This allows our joint solutions to go beyond proofs-of-concept and use cases, and instead tangibly illustrate how to scale manufacturing success. When technology is implemented locally, scaling can appear to only relate to management and coordination, which typically results in many enterprises experiencing eroding profits or reaching a dead end with their innovations.

The cornerstones to effectively digitizing and scaling a Smart Factory consist of:

- Teamcenter – Product Development

Siemens Suite of product lifecycle management (PLM) applications to deliver complex designs within global teams. - Opcenter – Operations Management

Manufacturing Operations Management (MOM) solution for a holistic digitalization of manufacturing operations. - Digital Twin – Virtualization

Collect digital data in real-time, cut costs, save time and increase productivity. - MindSphere – Industrial IoT as a service

Using advanced analytics and AI to power IoT solutions to the cloud. - Mendix – Low-code application development platform

Create programs from components without coding skills.

Partnering helps manufacturers pivot

When you combine Siemens’ global digital product and software portfolio with Atos’ secure and decarbonized digital platforms and services, you can access the knowledge and expertise of the most up-to-date manufacturing technologies and industry know-how.

As a valued Siemens partner, Atos is uniquely positioned to manage the whole end-to-end value chain of data with a proven industry-specific solutions and services portfolio. Combining global insights with local expertise enable successful, scaled collaborative innovation with clients. Our Alliance focuses on activating successful methodologies to accelerate the digital transformation journey by identifying performance gains, mapping capabilities and actionable consultancy.

Atos and Siemens achieve this by adhering to four key pillars:

- Enable the Digital Enterprise

- Co-create and innovate with customers

- Lead in security and decarbonization

- Nurture long-standing partnerships

Over the years, the Atos and Siemens Alliance has been powerfully transforming manufacturing enterprises worldwide through business and technology accelerators. We have combined our global capabilities and know-how in computing, analytics and IOT to help customers overcome the most complex digitalization challenges and realize opportunities through valid scale adoption of Industry 4.0 technologies.

Explore the insights of our partnership and get started with Smart Factory Studio.

Authors

Darren Laurie

VP, Global Client Executive Partner – SFA Digital Industries, Atos

Darren Laurie is Atos’ Global Client Executive Partner, overall responsible for the relationship with Siemens Digital Industries. This includes the strategic Alliance where he is deeply involved in the execution of the joint go-to-market with Siemens Digital Industries, their business units, and regional sales teams. With a passion for digitalization, Darren has been working with Siemens in various roles for 8 years, living in the UK.

Dr. Robin Just

Strategic Partner Manager for Atos at Siemens Digital Industries

Robin Just is a Siemens Digital Industries Strategic Partner Manager, globally responsible for all joint activities in the strategic Alliance between Atos and the different business units. He is a strong believer in the benefits of partnerships for end customers. Robin joined Siemens in 2000 and was in between also working for Atos and Worldline. He is living in Germany. Contact Robin.