Manufacturing Digital Transformation: The Imperative Journey

Today’s era of technological advancement has shifted digital transformation from being just a buzzword to an essential pivot for manufacturers. Companies must develop and execute a robust manufacturing digital transformation strategy to safeguard their competitive advantage in the fluctuating market dynamics and ever-evolving customer expectations.

The relentless acceleration of technological advancements has left manufacturers at the initial stages of digital transformation. A significant hurdle impeding progress in digital projects is the misalignment between Information Technology (IT) and Operational Technology (OT). This disconnection prevents a holistic view of operations, which is vital for successful digital transformation.

The role of an end-to-end ecosystem in manufacturing digital transformation: PLM, MES and digital twins

This is where Product Lifecycle Management (PLM) comes into play. PLM is critical in creating an effective end-to-end ecosystem by seamlessly integrating systems, processes, and people. It aids in modernizing IT and OT processes, thus constructing a much-needed bridge in the perpetually changing landscape.

The importance of PLM is emphasized by the anticipated growth of the PLM software market, which is projected to reach USD 9.22 billion by 2025. This growth signifies how instrumental PLM is in steering the journey towards successful digital transformation.

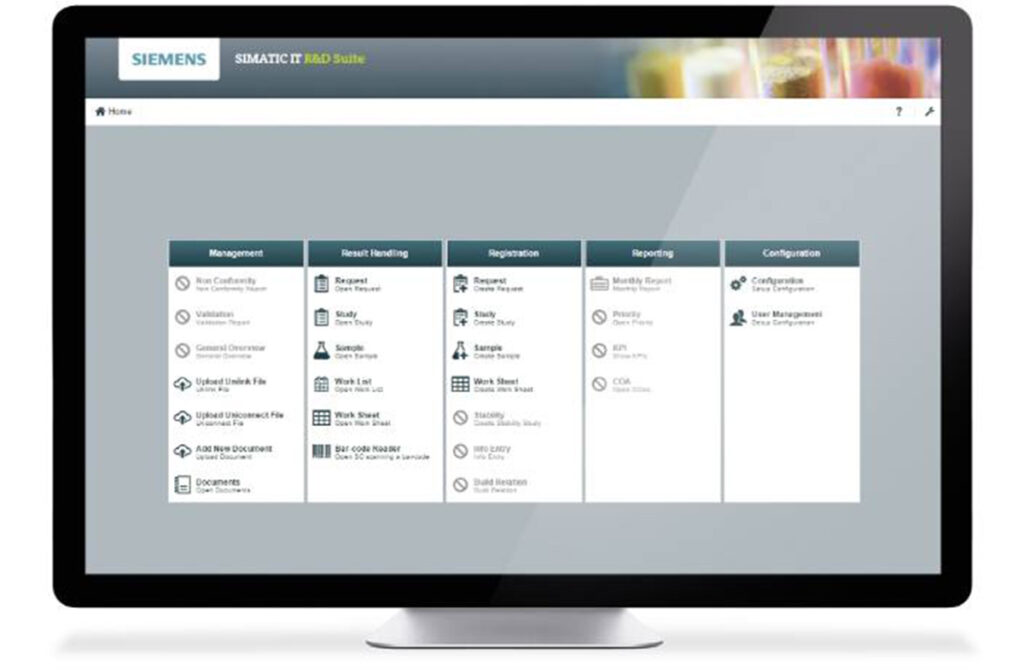

In the ongoing narrative of digital evolution, Manufacturing Operations Management (MOM) stands out as a holistic approach to overseeing various aspects of the manufacturing process. Within MOM, Manufacturing Execution Systems (MES) emerge as a specific software-based solution, pivotal in shaping this manufacturing digital transformation narrative.

The MES has surfaced as a crucial force. By actively managing and monitoring work-in-process on the factory floor, an MES provides real-time data that is invaluable in pinpointing inefficiencies, curtailing downtime, and enhancing productivity. The global MES market, expected to grow to USD 17.1 billion by 2025, testifies to its escalating importance in the digital manufacturing landscape.

The journey of a manufacturing digital transformation also introduces us to the groundbreaking concept of digital twins. These virtual replicas of physical assets are revolutionizing manufacturing processes by enhancing simulation capabilities, improving IT-OT integration, and facilitating efficient data collection. The digital twin market, projected to reach an impressive USD 48.2 billion by 2026, mirrors the profound impact of this technology on the industry.

Streamlining processes with low-code (business process automation)

The pivotal role of low code in a manufacturing digital transformation cannot be overstated. This technology simplifies application development and proves instrumental in optimizing processes within Product Lifecycle Management (PLM). By breaking down silos and fostering collaboration across various stages of product development, low-code automation enhances efficiency significantly.

Low code’s capacity to automate repetitive tasks expedites application development, ensuring swift adaptability to changes and maintaining a competitive edge. The projected growth of the global low-code development platform market, expected to reach USD 45.5 billion by 2025, emphasizes its crucial contribution to driving efficiency in the manufacturing sector.

Digital transformation in manufacturing is a complex process that involves integrating elements like PLM, MES, digital twins and business process automation. These tools enhance operational efficiency and pave the way for innovative solutions to longstanding challenges. As we delve deeper into the digital age, these technologies will persistently shape the future of manufacturing.

However, to truly succeed in this transformation, you need a trusted partner with the vision, the expertise, the people, and the solutions. CLEVR, a Siemens and Mendix partner, can be your trusted ally. As we continue our journey into the digital age, these technologies and partnerships will undoubtedly shape the future of manufacturing. Don’t wait for the future to happen; be a part of building it.

Contact CLEVR today to begin your manufacturing digital transformation journey.

About the author

Ech-chaimae Touarha is the Content Marketing Manager at CLEVR, contributing to its mission of “Building Tomorrow Together.” With over 20 years of domain expertise, CLEVR provides innovative and sustainable PLM and low-code solutions that enable businesses to streamline their processes and embrace digital transformation.