What’s new in Opcenter Quality 2312

Execute quality inspections and evaluate results for streamlined production capabilities

Opcenter Quality, which is part of the Siemens Xcelerator business platform of software, hardware and services, helps you support all of the quality procedures required in the product lifecycle. It covers the plan-do-check-act (PDCA) cycle, enabling the user to manage core quality tools and corporate quality.

Enhancing production inspection capabilities

With the latest version, the lot/batch dialogue has been enhanced to provide improved data traceability. All the information that was previously available in the original table has now been integrated into the left tab called “additional info sample”. If a row is highlighted in green, it indicates the corresponding column contains a selection list. Further, a new tab has been introduced that delivers additional information at the inspection order level. This new tab functions like the “additional info on sample” tab but primarily provides information specific to the inspection order.

Opcenter Quality 2312 brings you the following benefits:

- Execute quality inspections and evaluate results for streamlined production capabilities

- Use new properties to calculate statistics for dynamic sampling

- Improve capabilities in SPC, IGC and OGC web module

- Enhance support of standard requirements for the aerospace industry

- Enhance gage management process and usability

- Enhance application security requirements

Some features:

- Increased functionality for SPC calculations

- Dynamic sample calculation at inspection plan level instead of inspection characteristic level

- Enhanced usability for SPC, IGC and OGC web module

- Added SPC acquisitions to dynamize inspections based on lot size

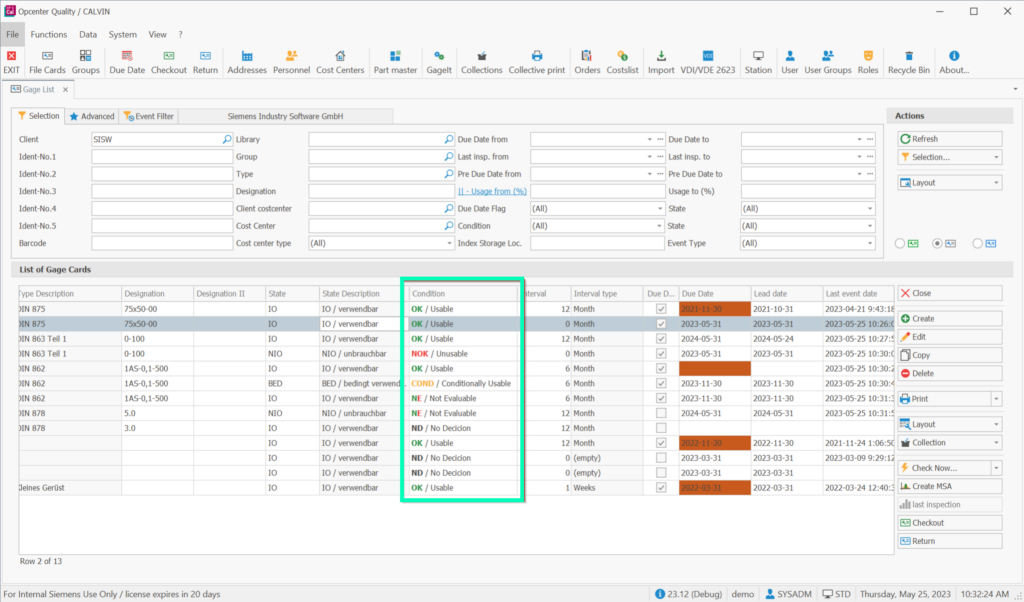

- Functions for improved usability of gage management

- New protocols for user password and authentication in applications

Already using Opcenter Quality? See what’s new in version 2312, or learn how to experience the benefits of closed-loop quality for best-in-class products with our videos.

Want to learn more? Opcenter Quality is a quality management system (QMS) that enables organizations to safeguard compliance, optimize quality, reduce defect and rework costs and achieve operational excellence by increasing process stability. The integrated process capabilities (control charts, statistics, quality gates) can detect production errors to avoid further processing and shipment of nonconforming material.

We have plenty to say about the benefits and features of Opcenter Quality, but our customers have stories to tell as well. Here are three examples of manufacturers that leverage Opcenter Quality for a competitive edge:

- Miba is one of the leading strategic partners in the international engine and automotive industry. Siemens Digital Industries Software solution helps Miba streamline global quality assurance work in pursuit of zero-defects initiative. Miba uses Opcenter Quality to lay the foundation for further digitalization steps. If you want to learn more, click here.

- Pepperl+Fuchs is a global company headquartered in Germany with more than 80 foreign subsidiaries on six continents and manufacturing facilities in Germany, the United States, Singapore, Hungary, China, Indonesia and Vietnam. To digitalize and globally streamline quality-related work across all locations, the company invested in Opcenter Quality. If you want to learn more, click here.

- Merit Automotive Electronics Systems is a global supplier of complex mechatronics modules and switches to the automotive industry. Reducing the amount of paper on the shop floors and having all history data available at any time has made Opcenter Quality an asset. It delivers full control and a reliable support tool for the managers and supervisors involved in the decision-making process.

If you want to learn more, click here.

Find out more about Opcenter Quality:

Opcenter Quality Gage Management

Siemens’ Opcenter Quality software helps manufacturers meet their quality goals

Opcenter Quality web pages.