Comprehensive Quality Management System (QMS) Software

How do you manage Quality within your company today? While organizations have diverse methods for successfully managing Quality today, Quality Management System (QMS) software is an important tool to provide the support they need to improve quality throughout the entire product life cycle.

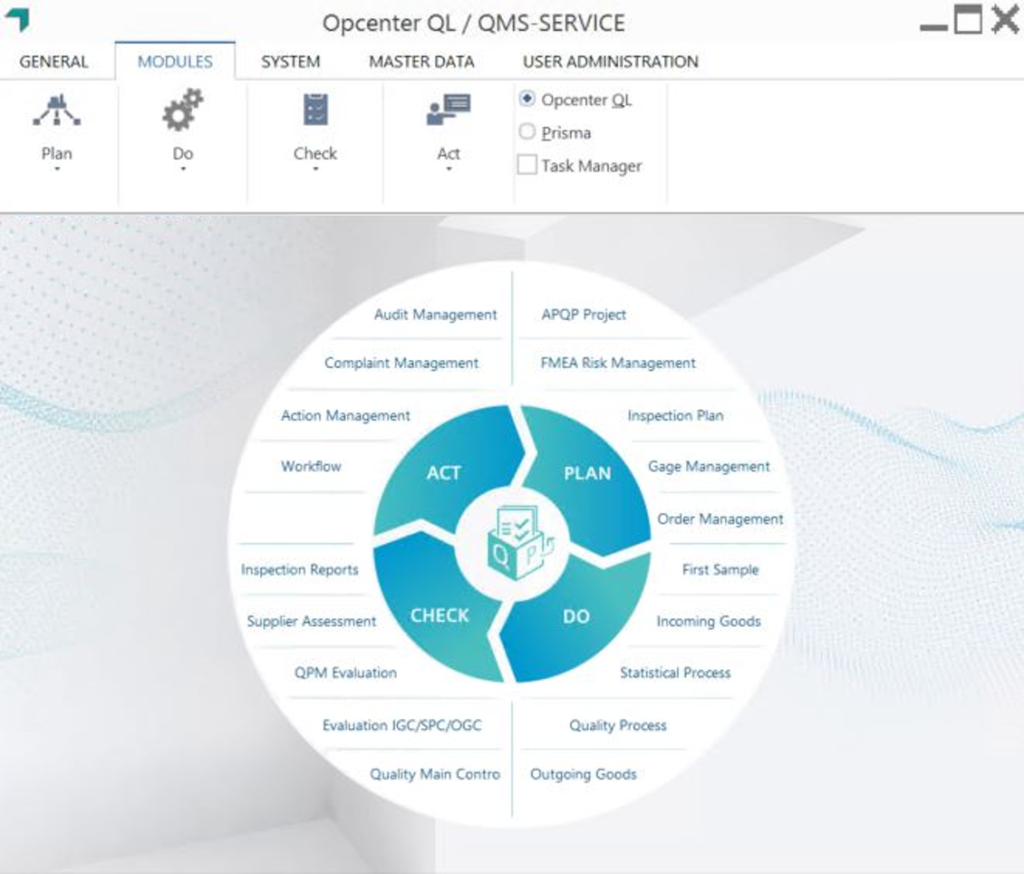

The plan-do-check-act (PDCA) cycle describes the phases of the continuous improvement process and forms the basis of all quality management systems. The cycle is designed to promote consistent and sustainable improvement of production processes.

- Plan involves the analysis of the actual status, the development of potential improvements and the compilation of conceptual realization.

- Do embodies the practical realization of the concept.

- Check generates reports, checks results of the test run, and sets the standard.

- Act involves wide-scale implementation of the new standard and regular monitoring through audits.

How does a QMS software support your quality team?

Opcenter Quality is a part of the Xcelerator portfolio of software and services from Siemens Digital Industries Software.

A comprehensive Quality Management System (QMS) software enables organizations to safeguard compliance, optimize quality, reduce defects and rework costs and achieve operational excellence by increasing process stability. It supports all quality-relevant processes required in production.

In the planning phase, the key quality processes to be monitored are Advanced Product Quality Planning (APQP), Control Plan, Failure Mode and Effects Analysis (FMEA) and Production Part Approval Processes (PPAP). In the production stage, the execution of inspections, non conformance detection and gage management become crucial. Complaint management and performance analysis, including Statistical Process Control (SPC), are the sub-sequential important tools. Closing the loop to generate continuous improvements, lessons learned are fed back to the planning phase. Adjustments to product design and manufacturing processes can bring about greater quality and efficiency.

Learn more about customer success stories:

Already using Opcenter Quality? See what’s new in latest version!