Opcenter Quality 13.1 has been released!

We are excited to announce the availability of Opcenter Quality 13.1! Using Xcelerator Share to extend your ability to collaborate internally and externally.

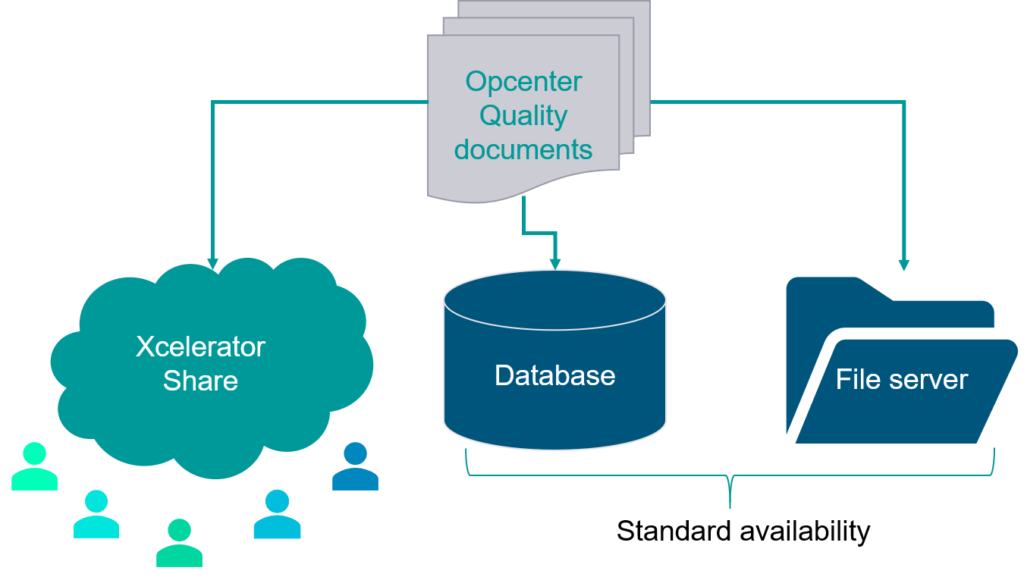

Extending collaboration with individuals and teams You can store any kind of document in Opcenter Quality, either on a file server or in a database. With Opcenter Quality 13.1, you have the option to use Xcelerator Share to store documents in the cloud. This capability enables more efficient internal data exchange. Using Xcelerator Share extends your ability to collaborate with individuals and teams to securely share files (such as quality certificates and 8D reports) with collaborators outside of your company

Opcenter Quality 13.1 brings you the following benefits:

- Use Xcelerator Share to securely share files inside and outside of your company

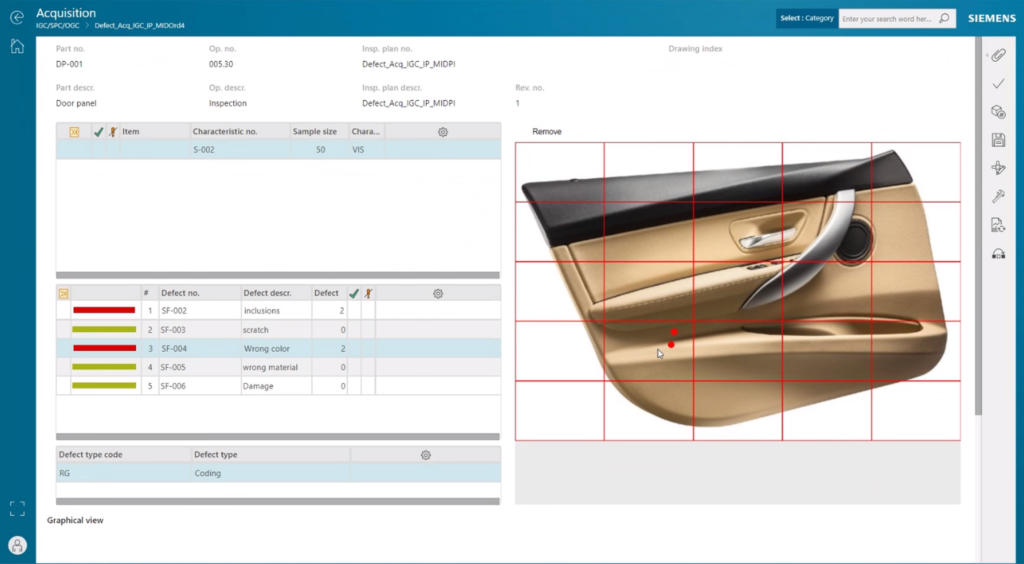

- Enhance your incoming goods controls with graphical acquisition of defect images

- Leverage faster creation of supplier or internal complaints from your goods controls

- Boost collaboration among international teams by using multilingual capabilities for FMEA

- Increase VDA requirements support for PPA

- Improve usability for gage management

Some features:

- Use Xcelerator Share to support Opcenter Quality

- Use IGC web to conduct graphical acquisition based on defect images or 2D-drawing

- Create a supplier or internal complaint using IGC/OGC web

- Import/export multilanguage MSR FMEA translations

- Use FSI to enhance the PPA

- Improve useability for Gage Management (CALVIN)

Already using Opcenter Quality? See what’s new in version 13.1, or learn how to experience the benefits of closed-loop quality for best-in-class products with our videos.

Want to learn more? Opcenter Quality is a quality management system (QMS) that enables organizations to safeguard compliance, optimize quality, reduce defect and rework costs and achieve operational excellence by increasing process stability. The integrated process capabilities (control charts, statistics, quality gates) can detect production errors to avoid further processing and shipment of nonconforming material. Find out more about Opcenter Quality.