GROB automates manufacturing of CNC machines for the automotive industry

GROB-WERKE GmbH & Co. KG (GROB) is a family-owned company and leading manufacturer of production plants and CNC machines for the automotive industry, ranging from universal machining centers to fully automated production and assembly systems.

GROB faces several business challenges, including:

- Designing leading-edge automotive production equipment

- Using standardization to manage high customization level

- Relying on global engineering collaboration

- Maintaining their leadership position in competitive industry

GROB owes a large part of its success thanks to the ability to anticipate and quickly respond to changing market trends using a high level of automation. With Siemens’ Xcelerator software portfolio, GROB’s engineers can design, engineer, and manufacture production equipment and CNC machines for the automotive industry.

Automate CNC machines in the automotive industry with NX CAM

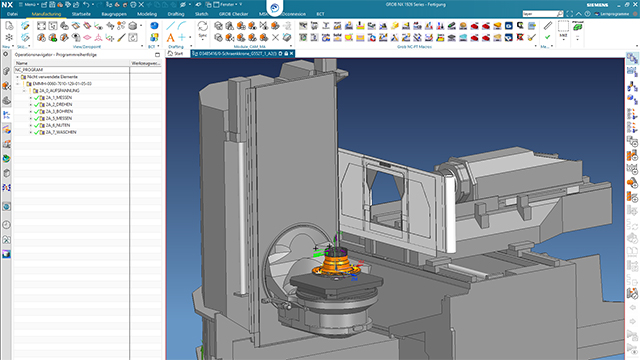

GROB engineers create a digital twin of each production machine and line using NX. They also use NX CAM to automatically create CNC programs using Feature-Based Machining. This capability helps GROB’s programmers to create a machining rule library containing standard bore types, pockets and surface definitions, including the tools required for machining operations. Before sending the CNC programs to the machine tools, the engineers simulate complete machining processes using the NX CAM’s machining simulation capabilities, ensuring error-free production on the shop floor.

To better collaborate, the engineers exchange 3D models between production facilities, using Teamcenter as the central information hub. These models are then CNC programed locally, making it easier for the engineers at each facility to adjust the CNC programs according to the available resources and equipment.

Using NX CAM for feature-based machining helped us automate design and CNC programming work. Recognizing 95 percent of GROB standard bore types and 70 to 80 percent of other features, the automatic feature recognition has reduced CNC programming time by 30 percent and considerably reduced the number of different tools used.

Christian Lisiecki Director and Head of Machining Systems GROB