From Additive Manufacturing to Machining: LIGHTWAY increases productivity with NX

Young, dynamic and innovative, LIGHTWAY GmbH & Co. KG is located in Niederzissen, a short drive from Bonn. One of the few companies in Germany to offer in-house expertise in design, 3D metal printing, CNC machining and robotics, LIGHTWAY is uniquely positioned to provide precision parts to its customers.

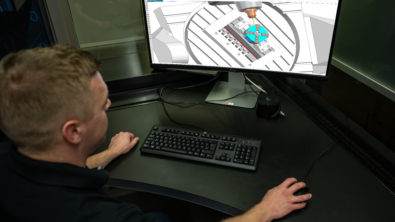

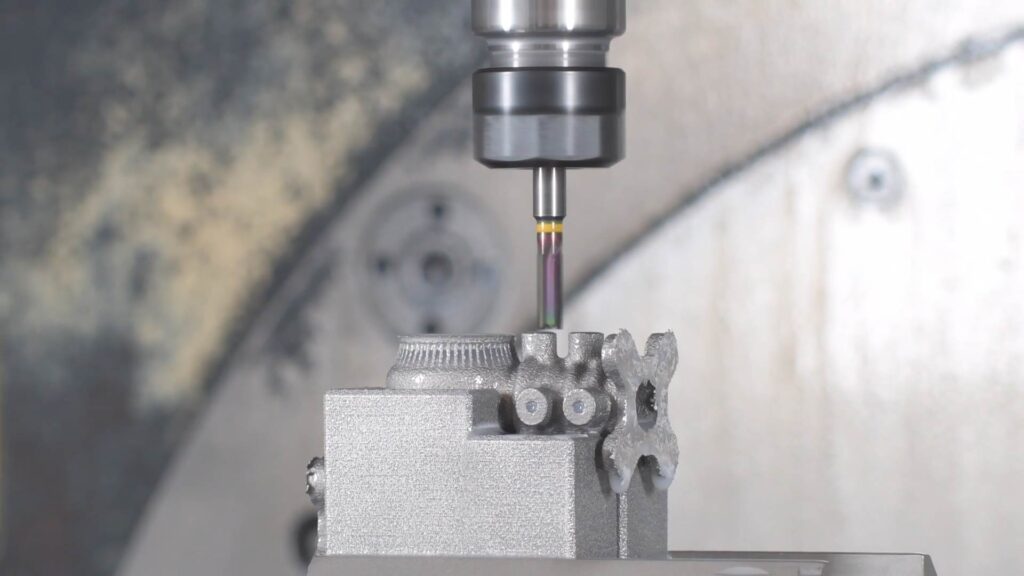

In this video, they talk about how they produce high-end components from the first idea to 3D printing and precision machining all the way to the final finished component using Siemens NX software.

LIGHTWAY leverages NX’s wide range of capabilities for additive manufacturing. The full integration of NX allows them to use 3D printed parts directly as raw materials for final machining in NX CAM software. Using advanced 5-axis machining capabilities, they are able to reduce programming and milling time using the most advanced milling processes possible. The template technology lets them reuse proven machining processes without much effort.

“By using Siemens NX throughout the entire process chain, we are much more flexible in component production,” says Pascal Schäfer, technical manager at LIGHTWAY. “We can react faster to customer requests. All our data is automatically connected. The devices, the AM module, the CAM programming – everything is updated automatically. We were able to create a new component from the first idea to a ready-to-use part within 10 days. With our former process, this would have taken several weeks.”

Learn more about LIGHTWAY (In German): https://lightway-3d.de/