The Design Alliance: Electronic and Mechanical

This is the first entry in “The Design Alliance” series.

Present Day

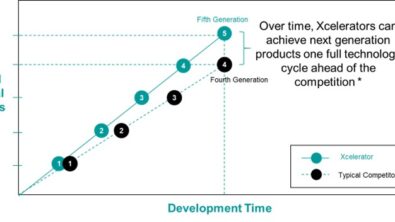

Look at any product you buy today. Chances are, not a single one is purely just an electronic or mechanical device. Truth is every product today contains both electronics and mechanical pieces. Not only that, but products are getting smarter, connected, and developing intelligence. In terms of the engineering and manufacturing perspective, we know that design complexity is outpacing legacy development where silos and manual processes dominate.

As electronics are now a requirement for products, it is essential that the mechanical and electronics designers are communicating to make sure that design changes are noted and coordinated with one another. The last thing product designers want when working on a team is to have conflicts in the design process. With a team of engineers ( large or small) it is crucial that the collaboration is there. An electro-mechanical design advantage could be a deciding factor for success now and for years to come…as discussed in this Next Generation of Design podcast episode.

What if I’m comfortable where my organization is at?

The unfortunate consequences of not being prepared in this alliance of M-CAD and E-CAD can be significant. In 2016, Aberdeen Group found that organizations (187 respondents) that had issues surrounding collaboration with M-CAD and E-CAD resulted in

- 53% will require additional resources to meet their business objectives for new products

- 32% will miss new product objectives as a result of poor collaboration

- 21% will experience manufacturing delays due to poor data quality and/or inconsistencies in new product designs

- 35% will require multiple ECO’s on new product designs in order to compensate for their digital transformation failure

You’ve already realized by now but the reality is: If you are bringing complex products to the market quickly, you will need multi-discipline solutions.

Take this global electronics instrumentation manufacturer for example.

This electronics manufacturer had its own digital transformation solution which proved an overall success. Copper exchange was the design teams most important item to collaborate between the electronics and mechanical disciplines. As we know, copper is inherently an electrical entity. Previously used M-CAD tools struggled due to the size and complexity of the data. For example, a satellite design may contain over 100-thousand components on a single layer of the design, and 3-4 million vias. This is a lot of data to consume. For this company, copper was required throughout the entire collaboration process and not just a simple sketch overlay. Intelligent net names and body information were required due to complex objects like RF circuits. On top of that, there were other complex data sets that required complex mechanical assemblies that constantly change throughout the process. As you can imagine, these were all factors that pushed this electronics manufacturer to complete a digital transformation. With a fully collaborative working environment this company now has a:

- Complete and synchronized library

- Full interference checking on both E-CAD and M-CAD

- Full collaboration of data to assist in collaboration and simulation!

An alliance between the electronics and mechanical disciplines are needed

Tight collaboration among the electronics and mechanical designers throughout the product design process is required to improve product designs and to support future innovations on product design. The above case study is just one of many thousands of organizations that have enacted in a digital transformation. Organizations that have made the alliance with E-CAD and M-CAD now see increased productivity, improved design robustness, collaboration and efficiency, and first-pass success. The full impact of E-CAD and M-CAD integration can’t be realized until a transformation of tools is complete. These tools must allow for everything that your product development requires. As previously mentioned above, the reality is: If you are bringing complex products to the market quickly, you will need a multi-discipline solution.

In the coming articles we will look at specific software solutions and case studies from around the world. Our goal is to guide you in the right direction for you and your organization. We want to see you succeed in your product development endeavors.

Stay tuned on more to come from “The Design Alliance Series.”

Read Article 2 of the Design Alliance here

Interested in this topic of electromechanical design?

Watch our Next Generation Electromechanical Design Webinar

In this webinar, Dave Walker and Nick Dauman will examine how electronics companies, suppliers and contractors can address the increasing product complexity (mechanical, electrical, electronic) and new technologies impacting electromechanical design in product development. NX delivers a holistic design approach that integrates the mechanical, electrical, and electronic disciplines and enables designers to respond to changing demands quickly and easily, increasing confidence in product performance.

Comments