If It Wasn’t for CAD, I’d Be an Accountant

We all have those moments when the old phrase “Timing is everything” truly applies to our lives:When you score the game winning goal, meet your spouse, or narrowly avoid an accident. In my life, timing has played a key role in my career, and both instances were CAD related: my education and my first “real” job.

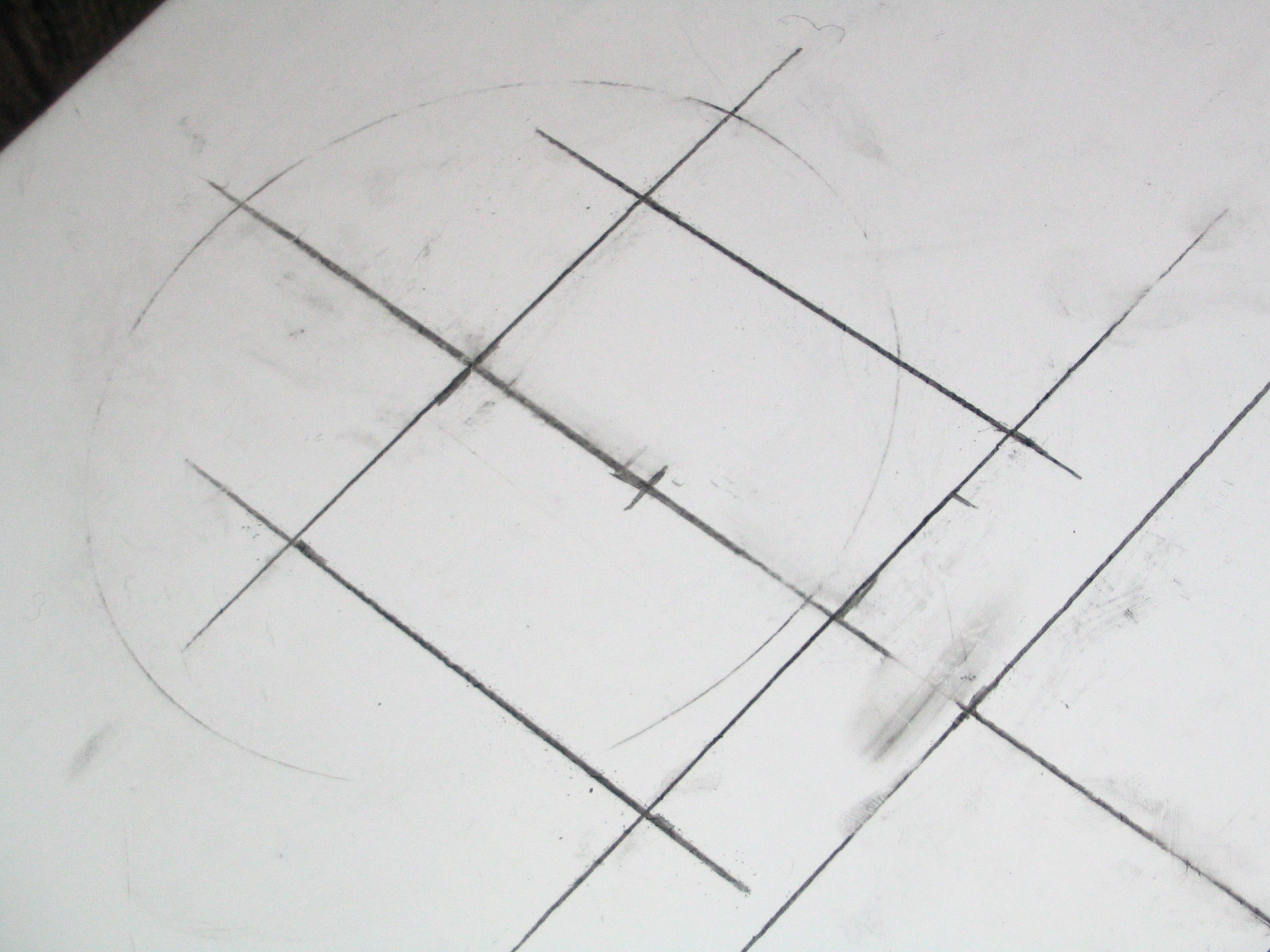

Like many of you, in college I had to take a couple of mechanical drafting classes. By mechanical, I mean pencil and paper. Looking back now, it’s almost humorous, but at the time it was a standard part of the curriculum and I actually enjoyed several aspects of the classes. I liked the process of taking an idea that was in my head and producing drawings that fully described the idea for everyone to understand. The process of projecting curves in one view into another view made sense to me. And sitting at the large drafting boards and using the attached ‘drafting machine’ was a nice break from reading books.

While I enjoyed the classes, the reality was that my drawings just didn’t look as good as those of the other students. The content and accuracy of my drawings was OK, but the quality was lacking. Lettering that was neither neat nor straight, varied line widths, pencil lead smudges… While many of these things would improve with practice, I had already begun to think that I didn’t want to do mechanical design for a living. While I’m ashamed to admit it, my inadequacies at the drafting board combined with other concerns I had with my major led me to seriously contemplate switching from a technical degree to a business degree.

Fast forward a couple of years to my first real job… When I graduated from college, jobs in the aviation industry were nonexistent, so I went back to my manual labor job that paid for college while I looked for a “real” job. Knowing I had a degree, the small machinery design company I worked for offered me the opportunity to work for a trial period in their design department.

As I feared, their design department was wall-to-wall drafting boards. However, over in the corner was a chubby, bearded guy with an office full of Mountain Dew cans and a CAD workstation! Fortunately for me, the company had just started to introduce CAD into their design department, and they were looking for designers who were willing to work on the computer. If my trial period in design would have started a few months earlier, I would have been “on the board”, struggling, possibly looking for a new job, and maybe even rethinking that business degree decision.

So why go on about the past?

As a product manager, I am constantly tasked with defining projects to enhance the CAD system, which is as it should be. We need to continually push our products to be faster, more capable, easier to use… However, we should also force ourselves to take a moment and look back to where we came from; to appreciate how far we have come and ensure we continue to learn from our past.

- Associative parametric product design

- Use of design templates

- The visualization and review of entire products

- Associativity from design through analysis and manufacturing

- Product management through multiple product configurations

- Associativity between requirements and design properties

- …and the list goes on.

Ten to 15 years ago, everyday design tasks still presented their challenges. For example, a new product requirement necessitated a manual series of events. You had to determine what aspects of the product are impacted by the requirement, consider how the design could be modified to accommodate the requirement, and a number of designers would manually implement the prescribed changes independently. Today many aspects of this process can be fully automated or drastically improved: Requirements can be directly associated to the physical model; digital mockup enables collaboration during the redesign process; parametric models can enable design changes; and associative interpart modeling enables the changes in one part to automatically propagate to associated parts.

What CAD will enable in the next 10 years is limited only by your ideas and my own. Regardless, I’m just glad I’m not an accountant.