How is product design changing with AI in CAD? | The role of AI in NX CAD

Welcome to another recap of the Next Generation Design podcast for the episode: AI-Enabled CAD: Enhancing Design Efficiency with Siemens’ NX. You can watch the full video version of the episode below.

On this episode of the Next Generation Design podcast, host Greg Arnot sits down with Shirish More, Senior Technical Product Manager for NX Architecture, AI, and PLM SaaS transformation, and Scott Felber, Senior Technical Product Manager from the NX Customer Success marketing team. They delve into how AI is revolutionizing the CAD landscape, transforming traditional design practices, and driving new levels of efficiency and innovation in engineering workflows.

Shirish and Scott discuss the evolving landscape of AI in mechanical design, from automating repetitive tasks to integrating advanced capabilities like generative design and real-time simulation. Discover how Siemens is leveraging AI and large language models to improve user interactions and deliver cutting-edge solutions within the NX suite, to empower designers to work smarter and bring products to market faster.

Find out how Siemens ensures data security while implementing AI, and how their approach allows companies to harness the power of AI without compromising intellectual property. Plus, hear about the impact of personalization in CAD software and how AI is creating a more intuitive, user-friendly design environment in NX CAD.

What you’ll learn in this episode:

What is the difference between AI, machine learning (ML) and deep learning?

We kick off the episode defining what we mean when we say “AI” or artificial intelligence, and the difference other terms such as machine learning and deep learning.

Shirish describes the differences:

- AI (artificial intelligence): The overall umbrella concept where machines are designed to think, learn and solve problems like humans.

- Machine learning: A type of AI where systems learn from data to make decisions or predictions without being specifically programmed for each task.

- Deep learning: More advanced than machine learning, this type of AI describes using layered neural networks to recognize complex patterns and then make decisions.

Shirish describes that from a Siemens perspective, we implement AI-enabled tools and capabilities into our software to help humans do more by automating tasks, making smarter decisions and providing predictive insights.

How are my data and IP protected when using Siemens’ AI tools?

Shirish notes that at Siemens, we are taking a multi-layered approach to protect users’ intellectual property which includes ensuring that AI models are trained within a secure environment, data exchange is encrypted, strict access controls and audit trails are in place. Additionally with AI components in NX, users can leverage their own IP for training machine learning models on-premises.

Scott adds that with Teamcenter, there is an additional layer of protection due to access control. So not only is data and IP protected from the outside world, but even within the company itself.

How does Siemens integrate AI into NX CAD to enhance productivity and user experience?

With Siemens being the first to introduce adaptive UI/command prediction into our CAD software, it’s no wonder that we continue to evolve NX by adding more AI and machine learning-enabled capabilities. Shirish says, “AI is going to be much more integrated with the things we are introducing in NX—from selection to suggestions and recommendations. I expect AI to create a much more personalized design environment.” He describes that the software will adapt to individual user needs, and he sees AI becoming second nature and doing actions in the background, where users won’t even realize it’s AI— it’s just helping them design faster.

Shirish and Scott also discuss trends that we are seeing with AI in CAD, and with them both having mechanical engineering backgrounds, they also express their own desires of what they would hope to get from AI in a product design process: the elimination of redundant tasks—reducing clicks and time spent on routine tasks, allowing more time to be dedicating to innovating. This idea drives the addition of AI capabilities in NX, so that you can reduce product development lifecycles, improve product quality and make the design process more intuitive.

Scott and Shirish hope that with the evolution of AI in CAD over time, AI will help validate and guide designs in real-time with intelligent suggestions based on the context of a design, as they expect the future of product engineering to be AI-driven. Aligned with this, Shirish mentions that we are working on developing generative AI in NX that can automatically generate designs or alternatives based on specific constraints and requirements. Additionally, we are looking into incorporating large language models (LLMs) to enhance user interaction, enabling engineers to ask questions, get assistance and manipulate and refine designs using natural language.

Will AI replace engineering jobs?

Shirish reassures customers that AI is not here to replace engineers and designers, it is here to support them and make their work more efficient so that they can focus more less on repetitive, time-consuming tasks and more on product development and creative and complex aspects of their work. Shirish says, “While AI can assist in generating design options or automating certain processes, it lacks the contextual understanding of the intent of the design. It’s always going to be a human who drives that aspect of their design.” With the capabilities in NX, it is necessary that a human user still previews the changes or suggestions made by AI to ensure that the correct information/data is being affected.

Scott adds that at a high level, companies are looking for their entire workforce to be more productive. With AI-enabled capabilities in NX, we look to help engineers get more things done with the same amount of people or in a shorter amount of time, which helps organizations to achieve that goal.

The future of AI generative design and conversational interfaces in CAD software

Greg asks Scott and Shirish more about a topic brought up earlier in the episode: generative design. Scott describes the concept of generative design: you give the system desired inputs, and it gives you a design based on those inputs. Shirish says that the purpose of generative design is to explore and optimize designs that may not have been immediately obvious, leading to more innovative, lightweight and cost-effective designs with the requirements and specifications in mind. He believes that going forward, generative design will play an important role in designing with sustainability in mind, where he might input, “Can you come up with a solution that keeps sustainability scores in mind?”

Greg then asks if Shirish and Scott see a conversational interface for product design on the horizons. Scott and Shirish affirm that that is absolutely something that is possible and it has been in the works for years with NX, “It’s just a matter of time before you can say ‘Change all the bosses to 30 mil,'” Scott says, noting that we already have voice commands in NX that allow you to talk to the software in a conversational manner to create your designs.

Shirish adds that with the integration of LLMs, it will be easier to interact with the software using conversational commands. A game-changing capability would be, for example, to identify the 10 heaviest components in an assembly. Currently, that would require many steps and commands. With the future of AI, you would be able to have a conversation with the software and say, “Highlight the 10 heaviest components,” and it provide that information.

As of the December 2024 release of NX, Design Copilot NX is available for NX CAD users via Value Based Licensing, and the module is being continuously improved. You can ask natural language questions, access detailed technical insights and streamline complex design tasks to design faster and smarter with less errors and rework.

AI features within NX CAD and how they will evolve

Shirish highlights that today, we have four key workstreams that we support with AI: personalization, prediction, smart human-computer interaction and AI services (where customres can train AI models with their own data). These capabilities in NX are available either as core modules via NX and NX X Design solutions, or as add-on modules via NX and NX X Value Based Licensing.

One module that Shirish specifically mentions in the “personalization” workstream is NX Command Prediction (adaptive UI). This module helps guide a designer and make the design process more efficient as it tracks how a user is using NX and in what context, then personalizes the user interface. Scott also adds that personalization with AI is huge as it enables companies to take their IP and design workflows and train NX to align to those workflows, which can help new or junior engineers as they come into the company and understand the design process. The system can also be retrained if and when needed.

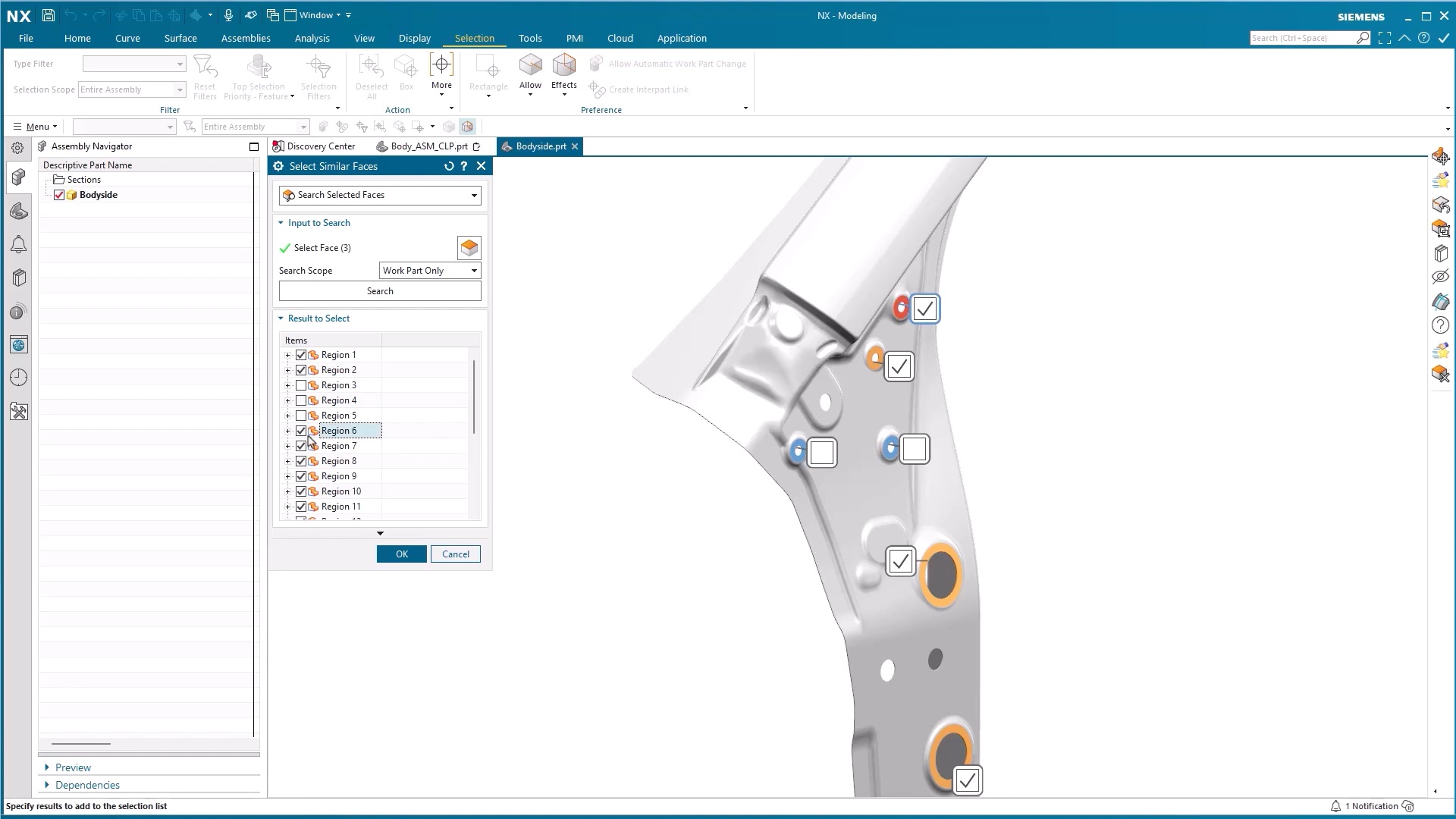

With prediction and smart-computer interaction, Shirish notes examples like NX Selection Prediction, NX Select Similar Faces and more, helping users to navigate through large assemblies. He adds that we even have capabilities to start predicting materials based on how the user has used NX or things they might have designed in the past.

The future of AI in NX is promising, as we focus to integrate AI even deeper into the design process and make NX more intelligent and responsive to user needs. We plan to expand the generative AI capabilities, enhance real-time simulation capabilities, improve user interaction including with conversational interfaces and more, so keep an eye out for updates.

In the episode, Shirish also goes beyond just the AI-enabled capabilities in NX and details two ways that we offer AI services.

How does NX Molded Part Designer leverage AI?

As we already explored a few other AI-enabled capabilities in NX, Greg asks specifically about another module, NX Molded Part Designer, and how it leverages AI. With NX Molded Part Designer, it’s all about reducing the number of design iterations and creating parts that are manufacturable since day one as the module leverages AI techniques to take into account the design, simulation and manufacturing steps of the product design cycle and speed up the design process.

NX Molded Part Designer is made possible by collective intelligence, tracking how users are using the software and learning from their actions how they may have designed molded parts in the past. With this knowledge as well as capturing best practices, NX uses an ML model that can give suggestions on a design. This includes for both the initial design as well as validation of the design. For example, it can predict draft angles, do quick validation checks and suggest changes if the design does not meet validation checks. This is just one module in NX that is enabled by AI technology.

Greg, Scott and Shirish close out the episode discussing how they see AI shaping the future of design as well as how SaaS impacts AI capabilities. For more details, check out the full video episode above or check out the audio version on the Next Generation Design podcast blog or on your favorite podcast platform.

Continue listening to the Next Generation Design podcast.

Want to learn more about NX CAD software? Check out our website or try it for free.

Comments

Leave a Reply

You must be logged in to post a comment.

Siemens’ article on AI in NX CAD demonstrates the powerful combination of artificial intelligence and engineering design, opening up solitaire bliss a future of creativity, efficiency and personalization in industry.