Siemens’ & SAP’s CALM partnership boosts energy operations

The energy (oil and gas, power generation), materials, and process sector (collectively referred to as “energy” here) is a challenging space to operate in. Two decades of commodity price volatility have not helped. In an effort to mitigate operational challenges, engineering, procurement, and construction (EPC) companies and owner-operators are working to optimize and connect their digital engineering and physical assets.

These organizations have been using many types of solutions, including product lifecycle management (PLM), enterprise resource planning (ERP), and supply chain management (SCM), as the backbone of different business processes. And while each digital solution provides value, connecting digital solutions with physical assets provides EPCs and owner-operators with significantly greater value.

Siemens and SAP are partnering, and the energy industry will benefit

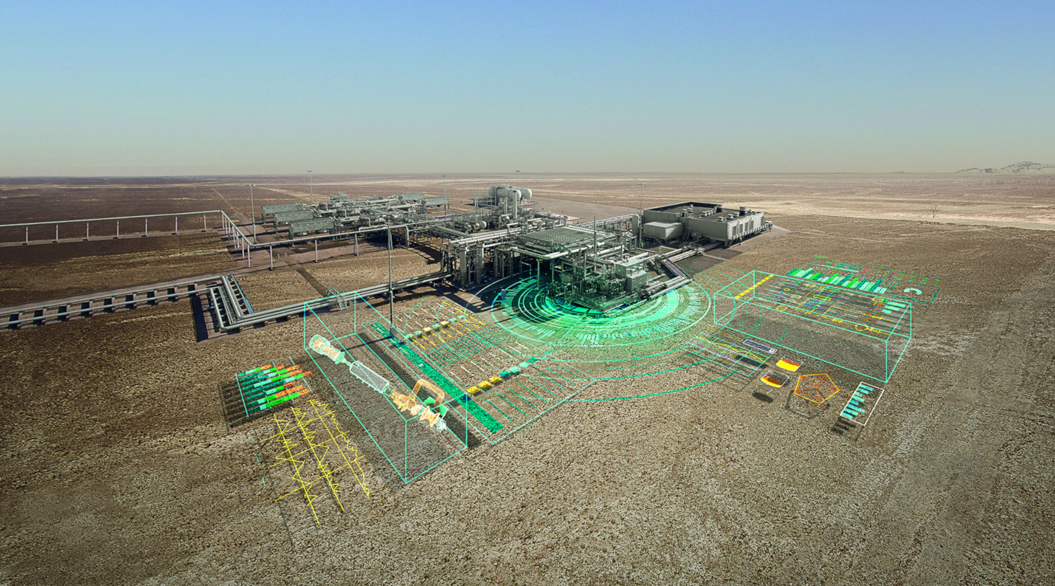

Siemens and SAP are leaders in their respective fields: SAP in the ERP, SCM, and other business process solution spaces; and Siemens in the PLM, product design, and adjacent areas. Through the Siemens partnership with SAP, customers can now select the best-in-class Capital Asset Lifecycle Management (CALM) solutions across the entire digital thread, from design through operations. The Siemens Teamcenter CALM product combines with SAP’s business process solutions, such as ERP and SCM, to form a unified, holistic framework for managing the lifecycle of an energy asset. By integrating Teamcenter CALM with SAP core business systems, energy executives can synergistically drive greater business and operations performance, despite today’s challenges.

The energy sector’s desire to change

Energy industry executives want to build more resilient, efficient, and profitable companies. This task is difficult in normal business environments. It’s even tougher in a highly volatile sector like energy. Forward-thinking executives are turning to the progressive competencies and technologies currently revolutionizing the manufacturing sector.

Systems engineering has great promise for the energy sector. Companies can use this set of practices and processes to design subsystems and components that fully leverage interconnectivity and interdependency across many engineering disciplines. Organizations can get the most out of systems engineering by adopting a PLM solution to manage their digital engineering assets, processes, and associated tasks.

Despite the clear benefits of systems engineering and PLM, energy executives and companies have been slow to adopt them. To ensure they survive and thrive in today’s volatile environment, energy companies must manage capital projects with a systems engineering mindset that incorporates the use of mature PLM solutions to ensure their “systems of systems” remain connected.

This post discusses the challenges that energy companies face and the benefits they can experience by connecting Siemens PLM solutions into an SAP backbone. Siemens and SAP have combined their complementary software solutions for product lifecycle, supply chain and asset management through an expanded partnership that enables customers to accurately represent digital threads and manage digital lifecycle solutions.

For a deeper discussion on realizing energy and utilities operational excellence using the digital lifecycle, download the Digital Lifecycle Excellence Brief.

Read on to learn more about the issues driving change and how Siemens and SAP together address these challenges. Let’s get started by looking at what issues are driving change.

Key challenges facing the energy sector

There’s no doubt about it: Energy executives face critical challenges today. But what is driving them to seek changes? There are several overarching issues. Some of the factors motivating executives to embrace a systems engineering approach and PLM technologies, include:

The need for sustainability: Government mandates require companies to decarbonize their global supply chains in an effort to help nations meet climate objectives. To comply with these directives, energy companies need transparency throughout their entire supply chain. This aspect of sustainability forces companies to make design, material, equipment, and sourcing decisions early in the project planning stage.

Disconnected stakeholders: Engineering in the energy sector is complex and multi-disciplinary, with energy companies focusing on mechanical, electrical, and construction disciplines. But electronics, control systems, and embedded software are more commonly playing a significant role too. Departments like procurement and maintenance are also crucial stakeholders. These departments work in silos with different toolsets and data models that weren’t designed to connect. However, keeping up with such modern demands increasingly requires a more robust collaboration capability.

Data problems: Using forensic analysis to understand and address plant breakdowns can help prevent other failures. But this analysis is typically complicated because operator companies don’t have the up-to-date engineering data necessary to pinpoint the cause of the failure. And even if they have the data, it may not be accurate. Further, the operator company has no easy way of ascertaining the accuracy of their engineering data.

Many of the challenges outlined here fall under the category of inadequate interoperability. A 2004 National Institute of Standards and Technology study estimated the cost of inadequate data interoperability in the U.S. capital facilities industry to be $15.8 billion per year. That cost works out to be about 4.2% of the capital asset cost on an annual basis and is never budgeted for. Experts assert that these costs are likely much higher today. There is a significant incentive for capital asset companies like energy producers to change how they operate.

The Siemens and SAP partnership enhances Capital Asset Lifecycle Management (CALM)

To improve CALM, energy sector companies can navigate these critical challenges by leveraging Siemens and SAP combined capabilities so that it becomes a key enabler for improving energy sector company operations. This approach brings together best practices from the systems engineering and manufacturing worlds with the back-office capabilities from ERP and SCM systems. It also employs PLM principles and methods from conceptual and front-end design, detailed design, and the planning, construction, and operation of an energy asset or a plant. With such a strong connection between the core ERP and SCM systems:

- CALM offers all stakeholders in the project and asset lifecycle credible real-time information, accurate digital engineering artifacts, and operational data about the plant. This information helps to drive crucial business decisions.

- CALM enables collaboration and manages digital engineering data from various sources. It also allows team members to view many types of distinct engineering representations in one central application. Serving as a single source of truth for the entire company, Teamcenter supports all energy industry standards.

- CALM consolidates the digital twin models making up a complex energy facility while maintaining the connection between multiple tasks and processes. These capabilities are facilitated in a secure, transparent, traceable, and dynamic environment.

- CALM translates and loads PlantCAD models and digital engineering data into a neutral format. Engineering teams can then manage operational changes down to the attribute level if needed.

Engineering teams can have even better outcomes with the enhanced CALM framework from Siemens and SAP. It was designed to optimize the performance of a capital asset—such as a plant, facility, or factory—across its entire lifecycle. With Siemens and SAP, CALM has become a powerful enabler that moves the energy industry towards true digital excellence.

Benefits of CALM across the lifecycle

The benefits of CALM span the entire lifecycle. It aids sustainability efforts by aggregating all engineering data related to design. This helps executives determine the exact carbon footprint of their projects while producing better designs with more accurate data. In addition, engineers can utilize simulation solutions to make informed design decisions and validate them to supplement these sustainability improvements.

CALM also helps engineers and executives in different departments make critical planning and execution decisions during the design and construction phase of the energy asset. Teams within the EPC company often work in parallel. This means many construction activities occur while the engineering design is still being finalized. Adopting a lifecycle approach ensures that construction engineers remain up to date with better visibility into the evolving design data to improve the alignment between construction and engineering. Real-time notifications empower better planning decisions for everyone.

An integrated CALM solution provides value in the middle of the asset’s lifecycle as well. It ensures a smooth handover of all digital engineering assets from the EPC company to the owner-operator company. The operator receives the latest digital twin models, which aid forensic analysis when breakdowns occur in an energy facility.

Of course, the deployed SAP and Siemens CALM solutions integrate seamlessly with the Siemens Industrial IoT (IIoT) solution stack, which accurately captures operating data. The IIoT platform analyzes and provides data to aid vital operating decisions based on artificial intelligence and machine learning models. Executives can access enterprise-wide data and insights associated with the solution stack through SAP and Siemens CALM. This integration enables the energy asset operator to respond faster to emergencies and to use the data to prevent future crises.

Embrace digital excellence

Operating a profitable, sustainable energy business is a herculean task, especially given fluctuating oil and gas prices. EPC companies and energy operators also face increased pressure to remain transparent and reduce carbon emissions. But the complex nature of the industry makes it difficult for departments to collaborate effectively. Additionally, energy companies often struggle to address breakdowns and prevent them from occurring again.

Many leading companies use SAP’s ERP solution as a backbone connecting their project execution business processes and associated data. Likewise, many industry vanguards leverage Siemens solutions to accelerate development and make more informed decisions. A combined ERP and CALM framework can help energy companies address these various challenges by providing a single source of engineering data across their entire operation. This improves sustainability, empowers better decisions, and helps prevent facility breakdowns.

Learn more

To learn how to improve operational efficiency and decision-making inside your energy business, download our Digital Lifecycle Excellence for Energy and Utilities Executive Brief. And stay tuned for the next Siemens and SAP information and events.

Comments

Leave a Reply

You must be logged in to post a comment.

By consolidating Siemens’ mastery in energy arrangements with SAP’s industry-driving innovation, the Quiet organization can possibly reform energy tasks and drive economical progressions. https://www.myccpay.vip/

Combining Siemens’ expertise in energy solutions with SAP’s industry-leading technology, the collaboration has the potential to revolutionize energy operations and propel sustainable advancements. https://www-liteblue.us/

By harnessing Siemens’ proficiency in energy solutions and SAP’s cutting-edge technology, this partnership holds the promise of transforming energy operations and driving significant progress towards sustainability. https://liteblueinsider.com/

Leveraging Siemens’ expertise in energy management and SAP’s innovative technological advancements, this collaboration is poised to revolutionize energy operations, marking a substantial stride forward in the pursuit of sustainability. https://www-iliteblue.com/

By harnessing Siemens’ proficiency in energy management and incorporating SAP’s cutting-edge technological advancements, this partnership is positioned to transform energy operations, representing a significant step towards advancing sustainability. https://nadevelopers.com/web-design-development/

JoinPD, an innovative educational resource, empowers educators to create interactive presentations that elevate classroom engagement. Visit https://joinpdinsights.com/

By harnessing Siemens’ proficiency in energy management alongside SAP’s cutting-edge technological advancements, this partnership is positioned to transform energy operations, representing a significant step forward in the journey toward sustainability. https://liteblueinsights.com/

Siemens is indeed outstanding in energy! This is what a great company needs to do! Improve your style https://topreplicas.cc

Through the combined expertise of Siemens in energy management and SAP’s innovative technological advancements, this partnership aims to revolutionize energy operations, marking a substantial stride in the pursuit of sustainability. https://www-wrongfuldeathlawyer.us/

I am writing to express my sincere interest in the Electrical Engineer position at Siemens, a global leader in technology and innovation. With a 6-year background in electrical Engineering field, I am excited about the prospect of contributing to Siemens’ ongoing success.

Siemens has consistently demonstrated a commitment to cutting-edge solutions and sustainable advancements, aligning seamlessly with my professional aspirations. The positive trajectory of Siemens’ future growth, marked by its focus on digitalization, renewable energy, and smart infrastructure, resonates with my career goals. I am eager to be part of a dynamic team that embraces innovation and drives positive change on a global scale.

My proficiency in making circuits and a proven track record of mcb and control panels make me confident in my ability to contribute effectively to Siemens’ projects. I am excited about the opportunity to leverage my skills for mutual success and be a part of Siemens’ journey towards a brighter future.

Many students are join Siemens through https://jobsiti.com/

Leveraging Siemens’ expertise in energy management and SAP’s innovative technological advancements, this collaboration is poised to revolutionize energy operations, marking a substantial stride forward in the pursuit of sustainability. https://litebluea.com/

Thanks for this https://jcpenneyassociatekiosk.page/

Thanks for this https://golfwatchs.com/

Thank you! We’re glad you liked it. Rent a car Lahore

Glad you liked it! Thanks for the feedback. I would like to

refer Rent a car Karachi

Glad you liked it! Thanks! Rent a car Rawalpindi

Glad you liked it! Rent a car Lahore

Thanks! Glad you liked it! Rent a car Rawalpindi

Thanks! Glad you liked it! Lx Digital Service

Thank you! We’re glad you liked it. If you ever need a top-notch car rental service in Pakistan, we’ve got you covered! Rent a car Lahore

Thank you! I’m glad you liked it. Rent a car Lahore to Islamabad

In Quick Draw , players are given a random word or phrase to draw within a limited time frame, adding an element of pressure and excitement to the gameplay.

By leveraging Siemens’ expertise in energy solutions alongside SAP’s advanced technology, this collaboration shows potential to revolutionize energy operations and make substantial strides towards sustainability. https://www-homeworkify.live/

The collaboration between Siemens and SAP through their CALM partnership is a significant leap forward in optimizing energy operations. By combining Siemens’ expertise in energy management solutions with SAP’s powerful digital platform, businesses can expect enhanced efficiency, greater sustainability, and streamlined operations. This partnership underscores a commitment to innovation and sustainability, paving the way for smarter energy management practices that benefit both businesses and the environment.

Regards, Rent a Car in Lahore

Siemens and SAP’s partnership under CALM heralds a new era in energy operations optimization. Their collaboration merges Siemens’ prowess in energy management solutions with SAP’s robust digital platform, promising heightened efficiency, enhanced sustainability, and smoother operations for businesses. This alliance underscores a joint dedication to innovation and environmental responsibility, setting the stage for more intelligent energy management practices with dual benefits for businesses and the planet.

Regards, Rent a Car in Pakistan

The alliance between Siemens and SAP through their CALM partnership marks a significant advancement in optimizing energy operations. With Siemens’ expertise in energy management solutions combined with SAP’s powerful digital platform, businesses can anticipate improved efficiency, heightened sustainability, and streamlined operations. This collaboration underscores a shared commitment to innovation and environmental stewardship, paving the way for smarter energy management practices that deliver benefits for both businesses and the planet.

Regards, Rent a Car in Islamabad

Siemens and SAP’s CALM partnership boosts energy operations, offering improved efficiency and sustainability through innovative solutions on a powerful digital platform.

Regards, Rent a Car Lahore

Many thanks for the enlightening update! I extend a warm invitation for you to explore my blog, ‘Insight’, where a treasure trove of insightful articles awaits. I eagerly anticipate your valuable feedback and positive impressions. Liteblue login portal

El sitio web de John Hanley PhD ofrece información sobre sus entrenamientos y servicios de coaching. Hanley, creador de la trilogía de entrenamientos de Transformación, se enfoca en empoderar a las personas para crear una vida que amen. Ofrece programas como el Básico, Avanzado, y PL-VIA. La web presenta detalles sobre próximos eventos, consultoría corporativa y una tienda online. Además, hay una sección de testimonios y opciones para mantenerse actualizado sobre sus actividades.

Para más información, puedes visitar https://johnhanleyphd.com/

Fantastic insights on elevating energy business operations through capital asset lifecycle management paired with SAP. It’s crucial how the integration of such systems not only streamlines operations but significantly advances sustainability efforts in the energy sector. As organizations look to implement these solutions, the role of comprehensive digital strategy and precise marketing cannot be overstated. At Digitology https://digitology.co we specialize in crafting digital marketing strategies that enhance online presence and drive engagement, crucial for businesses undergoing digital transformation. Partnering with a seasoned digital marketing firm can provide the visibility and traction needed to maximize the benefits of sophisticated asset management systems like SAP.

Siemens’ and SAP’s CALM partnership signifies a strategic collaboration aimed at enhancing energy operations. Leveraging advanced technologies, they aim to drive efficiency and innovation in the energy sector. how to login ehallpass

Siemens’ and SAP’s collaboration in CALM signifies a significant advancement in energy operations. This partnership harnesses innovative technologies to optimize efficiency and sustainability, driving transformative change in the energy sector. how to login liteblue login portal

The Siemens and SAP CALM partnership is a game-changer in energy operations. By combining expertise and technology, they’re revolutionizing efficiency and sustainability. This collaboration sets a new standard for innovation in the energy sector. https://ncedcloudinsider.com/

The Siemens and SAP CALM partnership is a game-changer in energy operations. By combining expertise and technology, they’re revolutionizing efficiency and sustainability. This collaboration sets a new standard for innovation in the energy sector. https://ireceiptify.com

we specialize in crafting digital marketing strategies that enhance online presence and drive engagement, crucial for businesses undergoing digital transformation. Partnering with a seasoned digital marketing firm can provide the visibility and traction needed to maximize the benefits of sophisticated asset management systems like SAP. https://my-pascoconnect.com

The collaboration between Siemens and SAP CALM marks a significant shift in energy operations. Through the fusion of their respective expertise and technology, they are reshaping efficiency and sustainability paradigms. This partnership establishes a groundbreaking benchmark for innovation within the energy industry. https://www-ncedclouds.com/

By combining expertise, technology, and innovation, they drive efficiency and sustainability, ushering in a new era of transformative energy management solutions. psychiatrist frisco https://acapstx.com/

Like the convergence of two mighty rivers, their collaboration promises to reshape landscapes, powering sustainable solutions and illuminating pathways towards a greener future. kinexpodiatrytx https://kinexpodiatrytx.com/

It’s like two powerhouses joining forces to not only streamline processes but to also pioneer sustainable solutions for a brighter, greener future. https://pulsewide.com

Like two powerhouses coming together to not only expedite procedures but also pioneer sustainable solutions for a brighter, greener future.

https://kmfusa.website/

This collaboration enhances operational efficiency, promotes sustainability, and drives innovation, setting a new standard for the energy sector. https://ncedcloudinsights.online/

It’s more than just a collaboration; it’s a fusion of expertise, technology, and vision, propelling the industry towards sustainability and resilience. Logininsights https://logininsights.com/

Siemens’ and SAP’s CALM partnership signifies a strategic collaboration aimed at enhancing energy operations. Leveraging advanced technologies, they aim to drive efficiency and innovation in the energy sector. how to login ehallpass

It’s like two powerhouses joining forces to not only streamline processes but to also pioneer sustainable solutions for a brighter, greener future.

how to access library genesis

Together, they’re not just revolutionizing energy operations; they’re shaping a sustainable future powered by cutting-edge technology and strategic alliances. https://cookecleans.com/

It’s a testament to the power of synergy in driving transformative change and paving the way for a smarter, greener tomorrow. Learn More

Energy industry executives want to build more resilient, efficient, and profitable companies. This task is difficult in normal business environments.

Regards, Rent a Car Lahore to Islamabad

By combining Siemens’ expertise in energy technology with SAP’s cutting-edge digital solutions, this collaboration heralds a new era of efficiency, sustainability, and innovation. https://ourdogbitelawyer.com/

I have tried siemens products and they have the best one. https://colegia.info

The collaboration between Siemens and SAP through their CALM partnership marks a significant advancement in the energy sector. https://iganonyinsights.online/

The collaboration between Siemens and SAP through their Capital Asset Lifecycle Management (CALM) partnership signifies a monumental leap forward for the energy sector. By integrating their extensive industry expertise and innovative digital solutions, Siemens and SAP are enhancing operational efficiency and sustainability. This partnership not only streamlines asset management but also fosters a data driven approach that is essential for future proofing the energy and utilities landscape. The synergistic efforts of these two industry leaders are set to drive substantial improvements in both economic and environmental performance, making a significant impact on the global energy sector. read more about E hall pass Classlink.

This partnership isn’t just about software integration; it’s about reshaping the energy landscape, empowering organizations to harness data-driven insights for smarter, https://dijinationstaffing.com/

This collaboration integrates Siemens’ expertise in industrial automation with SAP’s strength in enterprise software, providing a robust platform for managing the entire lifecycle of energy assets. https://njmcdirectpay.us/

This collaboration combines Siemens’ industrial automation expertise with SAP’s enterprise software capabilities, creating a powerful platform for managing the entire lifecycle of energy assets. www-njmcdirects.com

Thanks a lot for your support. https://www.onebloodrewards.website/

Siemens and SAP have joined forces to enhance energy operations through their Capital Asset Lifecycle Management (CALM) partnership. Let me break it down for you:

Challenges in the Energy Sector:

The energy industry (including oil and gas, power generation, and materials) faces operational challenges due to two decades of commodity price volatility.

Engineering, procurement, and construction (EPC) companies and owner-operators strive to optimize their digital engineering and physical assets ehall

thank you for this support. https://www.ncedcloud.run/

This collaboration promises to redefine efficiency standards in the energy sector, setting a new benchmark for sustainable technology integration. https://receiptifyinsights.com/

Great information. I will check out the rest of your blog. Subway Listens

The energy sector faces significant challenges, exacerbated by volatile commodity prices. Integrating Siemens’ PLM solutions with SAP’s ERP and SCM systems offers a robust framework for managing digital and physical assets, enhancing operational efficiency and resilience in a complex environment. This partnership model, akin to systems engineering in its approach, highlights the importance of streamlined processes—a critical need echoed in sectors like liteblue. United States Postal Service

The combined strengths of these industry leaders are set to drive innovation, optimize processes, and pave the way for smarter, greener energy solutions. https://monopolydicelinks.com/

This collaboration leverages Siemens’ expertise in industrial automation with SAP’s powerful software solutions to enhance efficiency, optimize resource management, and drive innovation in energy systems. https://njmcdirecthelp.me/