On-demand webinar: The predictive digital twin for the oil and gas industry

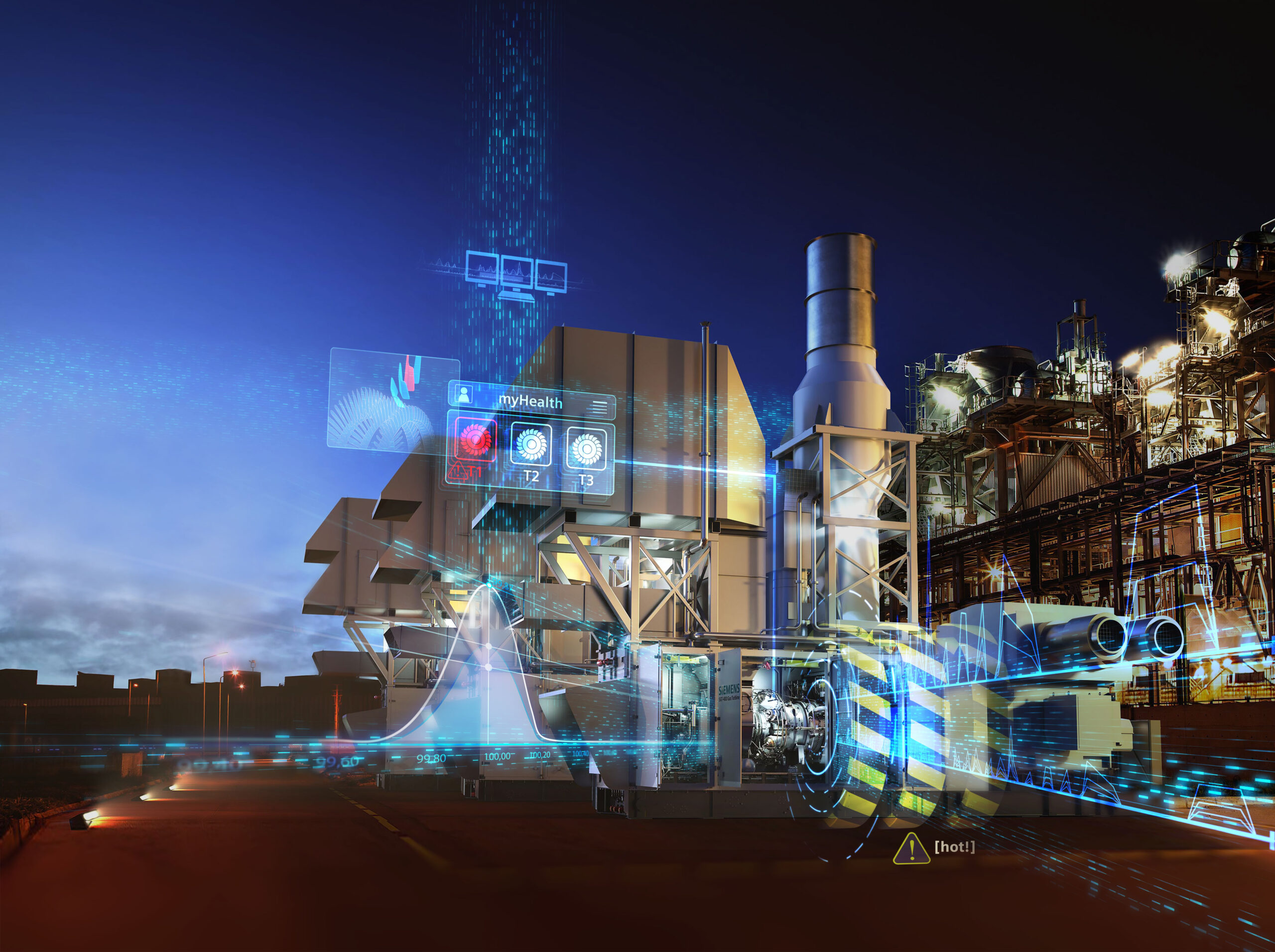

To thrive in the ultra-volatile oil and gas industry, companies must continuously improve their operational efficiency. With digital technology adoption slower than other industries, oil and gas businesses can gain far-reaching benefits from adopting digital twins, virtual representations of a physical product, system, process or facility.

Digital twins are based on engineering and operational data. They help oil and gas operations make data-driven decisions, increase collaboration and predict responses to future scenarios.

Watch our webinar on upgrading digital twins with predictive engineering analytics

With more data, a digital twin becomes better informed, helping it provide stronger insights and benefits. If data is unavailable or insufficient, predictive engineering analytics can fill the data gap. Check out our webinar to learn how predictive engineering analytics takes digital twins to the next level by combining multidisciplinary engineering simulation with intelligent reporting and data analytics.

In the webinar, you’ll view a demonstration of an oil and gas digital twin helping ensure the integrity of a heat exchanger. This includes high-fidelity finite element analysis (FEA) and computational fluid dynamics (CFD) forecasting flow distribution and heat transfer. It can occur because the digital twin uses predictive data beyond the available temperature data.

You’ll also view a demonstration of predictive data for flow assurance in subsea production. By using reduced-order models to predict hydrate formation risks in real-time, engineers can make quick reactions in critical situations.

Read our flipbook to learn how digital twins help improve operational efficiency

In our flipbook, you’ll learn how a digital twin helps improve operational efficiency by analyzing, understanding and predicting operational issues. This can provide oil and gas companies with a critical advantage while potentially reducing operational costs.

With oil and gas equipment and facilities remaining active for multiple decades, extending the lifespan of these expensive assets means massive long-term savings. At the same time, reducing planned and unplanned downtimes can save millions of dollars.

The possibilities of digital twins are virtually endless

Oil and gas ranks behind other industries in digital maturity. However, adopting digital twins can dramatically improve innovation inside oil and gas companies by giving engineers deeper insights into system behavior, enabling data-driven decision-making and fueling collaboration.

With this technology, oil and gas companies can improve their operational efficiency while better navigating economic uncertainty.