Blog Series: Smart factory insights: Opcenter IPL in action, Part 2

Part 2: Optimizing efficiency with reduced side inventory

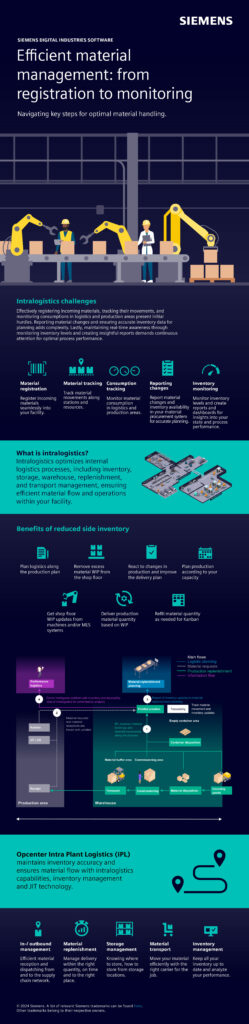

In our previous post, we introduced Opcenter Intra Plant Logistics (IPL). Now, let’s explore one of its key features: reduced side inventory. This approach can significantly improve operational efficiency and responsiveness to market demands for electronics manufacturers.

Key benefits of reduced side inventory

Implementing reduced side inventory offers several advantages that can transform your manufacturing processes:

- Financial impacts

- Improved working capital through reduced tied-up inventory – especially for electronics manufacturing service (EMS) providers with razor thin margins, intelligent management of the component inventory is key to maintain profitability and competitiveness in the market.

- Lower risk of component obsolescence – increasing use of quality sensitive materials like moisture sensitive devices and expiring materials require systematic and often complex control mechanisms as well as excellent planning processes to avoid costly waste and scrap. A smaller inventory is a simple strategy to reduce the financial risk posed by these components.

- Operational benefits

- Optimized production floor space utilization – centralizing material inventory in warehouse locations frees production floor space allowing for optimal production flows and increased production capacity in the same physical footprin

- Enhanced production flexibility to meet changing demands – smart intralogistics and inventory execution processes adapt and align with manufacturing execution to promote a focus on best-in-class manufacturing processes.

- Quality improvements

- Better product quality due to newer components – along with the financial impact of component obsolescence that was mentioned above, reducing the side inventory increases the material turnover rate ensuring that components are not sitting in storage subject to corrosion, oxidation, and other aging affects that may poorly impact product quality

- Improved traceability with smaller, more manageable inventory – Traceability accuracy suffers from a large inventory, a constant churn of materials between warehouse and production, and manual processes which creates many opportunities for improper handling and data collection. Reducing the side inventory decreases the risk of traceability mistakes contributing to improved product quality

How Opcenter IPL enables reduced side inventory

Opcenter IPL provides a suite of features designed to support and maintain reduced side inventory:

- Align logistics with production plans – smart inventory execution starts with aligning the logistics flow with the manufacturing execution, and this begins with the initial production plans to ensure that the correct logistics strategies are prepared and the material delivery flow is aligned with the work order schedule.

- Remove excess material WIP from the shop floor – the shop floor should only contain the WIP products and component materials needed for active or pending production. Unneeded materials and products should be stored off the shop floor in centralized locations and called to the floor automatically as needed based on the manufacturing execution.

- React quickly to production changes and improve delivery plans – any number of events can cause changes to the production schedule, such as unplanned downtime, unavailable material or resources, or urgent changes to the work order schedule. IPL automatically adapts to the production change and adjust the delivery schedule to align with the new plan, and the reduced, centralized inventory minimizes the work needed to physical return and re-issue new materials to production

- Plan production based on actual capacity – IPL enhances the planning and scheduling processes by providing detailed information about the status of inventory deployed across the facility contributing to accurate production plans.

- Receive real-time shop floor WIP updates from machines and MES systems – Automatically adapting logistics flows to the manufacturing process is enabled with real-time information from the shop floor including work order schedule and progress and the usage and consumption of components in production.

- Deliver production material quantity based on WIP – based on real-time information from the production execution, only the material needed for the upcoming production steps needs to be delivered periodically throughout the day. This keeps the side inventory lean and reduces the work needed to react to changes in production.

- Refill material as needed for Kanban systems – implementing ekanban tracking systems increases the efficiency of logistics processes by removing the need to manually collect and process Kanban cards. IPL will monitor the Kanban inventories and automatically trigger replenishment with inventory thresholds are exceeded.

These capabilities allow manufacturers to maintain lean inventory levels while ensuring production needs are met efficiently.

Best practices for reduced side inventory in electronics

Implementing reduced side inventory requires careful planning and execution. Here are some best practices that can help electronics manufacturers optimize their inventory management:

- Implement just-in-time (JIT) delivery for high-volume components

- Utilize Kanban systems for managing frequently used materials

- Leverage data analytics for accurate demand forecasting and inventory optimization

- Continuously monitor and adjust inventory levels based on production needs

By adopting these practices, manufacturers can streamline their material flow, reduce costs, minimize bottlenecks, and enhance productivity.

Transforming electronics manufacturing through optimized inventory management

Reduced side inventory, enabled by Opcenter IPL, can significantly improve efficiency and agility in electronics manufacturing. Manufacturers can reduce costs, improve quality, and respond more quickly to market demands by optimizing inventory levels. This approach increases production efficiency and product quality while reducing the risk of errors, returns, and rework.

Our next post’ll explore how Opcenter IPL addresses specific intralogistics challenges in the electronics industry. We’ll discuss strategies for overcoming hurdles in material tracking, consumption monitoring, and inventory management, providing you with insights to enhance your manufacturing operations further.