From lean to smart semiconductor manufacturing with real-time reporting and analytics (Part 2 of 3)

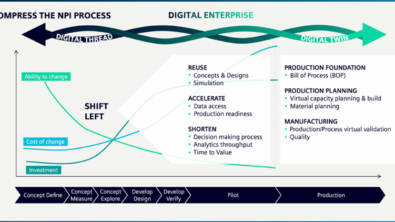

Traditional lean manufacturing brings benefits, but smart manufacturing can propel progress further to amplify profit margins and foster adaptability in semiconductor manufacturing. In our first post, we talked about shifting left for smart manufacturing. This next post in the series brings us to the execution phase. Executing is where we realize the gains we envisioned in the planning and scheduling phase. So, let’s take a closer look at the key executional components in making semiconductor manufacturing smart.

Smarter automation in semiconductor manufacturing

The key to realizing this gain is automation. There can be as many as 1,400 process steps in a semiconductor fab.1 Automation, a key cornerstone of Industry 4.0, helps drive maximum utilization, efficiency and flexibility.2 Implementing automation in a fab can sometimes feel like a bottomless drain on resources and time. Like any digital project, it is important to ensure you have a clear vision for implementation – what do you want to achieve out-of-the-box (OOTB) and what does your roadmap look like? Again, managing change is important – semiconductor fab production sites are often modified and the equipment in those sites are constantly being added or deleted. It is imperative to have the right automated system that can provide this level of fab and equipment flexibility and adaptability.

Gaining increased quality and reliability

Diverse applications in industries like automotive, medical and aerospace and defense have driven an increased focus on quality and reliability. Because the safety of humans can potentially ride on the performance of a single chip, it is important that we know everything we can about that chip, from where it was made and what part of the wafer it originated from, to intermediate test results as it proceeded through the fab. The International Organization for Standardization (ISO) standards like 26262 – which governs functional safety – require traceability, data provenance which includes the record of ownership of work done and when, plus requirements definition through verification and validation all the way to final test and qualification.3

Better back-end semiconductor manufacturing integration

It doesn’t just stop with the fab. The lines are blurring between fab processing and backend packaging. Fabs are doing process steps like through silicon vias (TSV) and wafer level fanout. Semiconductor assembly and test services (SATs) are investing in some simple versions of wafer processing steps like etch and deposition and doing hybrid bonding – a face-to-face connection of wafers.

Leveraging closed-loop real-time reporting and analytics

Digital transformation has inspired a new phrase: Data is the new oil. But data is only valuable if you know how to extract knowledge and insights that help drive actions. Semiconductor fabs, particularly when connected through industrial internet of things (IIoT) techniques, can generate massive amounts of execution and performance data. The key is to figure out how to collect, store, process and ultimately analyze data to extract the descriptive – what happened, and the prediction – what will happen, and the prescription – what should I do?

Orchestrating components for improved semiconductor manufacturing execution

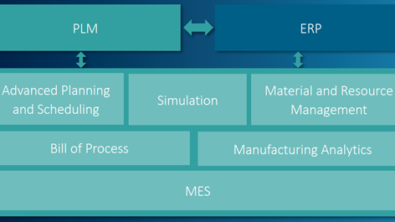

How do you orchestrate these components to unleash smart manufacturing in the semiconductor industry?

• Learn more about how a fully connected smart factory can deliver significant opportunities for continuous improvement in the Smart Manufacturing for Semiconductors eBook.

• For a deeper dive into the advantages of real-time reporting and analytics, download the reporting and analytics eBook: Siemens/real-time-reporting-and-analytics-e-book-pdf.pdf

Sources

1. “Chipmakers Are Ramping Up Production to Address Semiconductor Shortage. Here’s Why that Takes Time,” © Semiconductor Industry Association, February 2021.

2. Johnson, Clint; “A guide to modern factory automation and Industry 4.0 in manufacturing,” August 2020.

3. Murphy, Bernard; “Traceability and ISO 26262,” November 2021.

Blog co-authored by Melville Bryant, Siemens Digital Industries Software