ASTER Technologies strengthens Siemens digital thread for optimized PCB manufacturability

Siemens EDA is pleased to announce its acquisition of ASTER Technologies, a trusted name within the PCB design industry with more than 30 years of focus on verifying, assembling, and testing PCB assemblies.

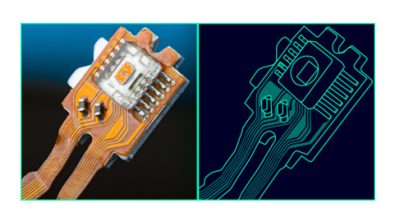

Founded in 1993, and based in Cesson-Sévigné, France, ASTER Technologies provides compelling design for manufacturing (DFM) physical design verification software solutions for PCB fabrication, assembly and test, alongside robust test coverage analysis and test programming capabilities. Its flagship product, TestWay™, is renowned for its best-in-class design for test (DFT) planning and implementation, enabling companies to prepare designs and implement robust test strategies early in the PCB assembly manufacturing process. TestWay complements Siemens’ Valor’s design for fabrication (DFF) and design for assembly (DFA) capabilities, creating a truly comprehensive (DFM) solution.

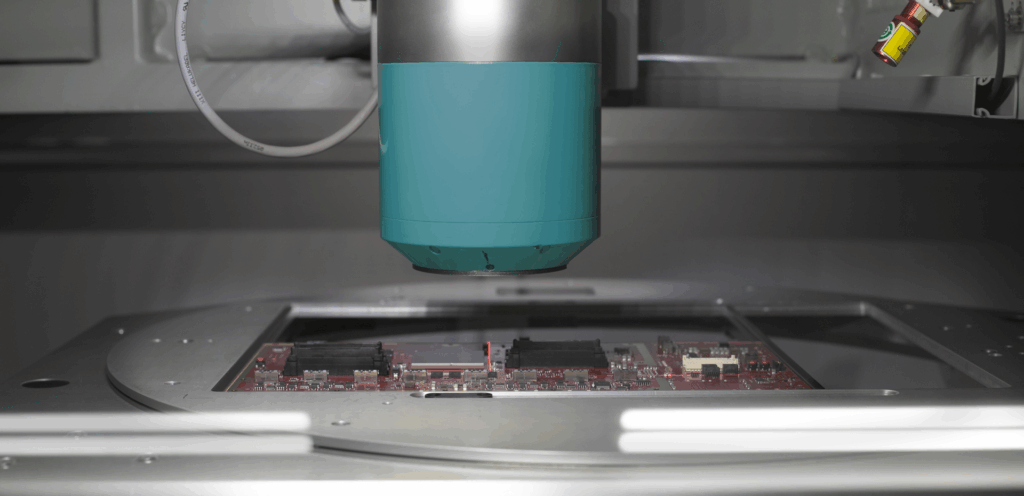

ASTER Technologies brings proven capabilities for test coverage analysis, testability insight, and the practical workflows needed to translate test strategy into production execution across inspection and test stages such as SPI, AOI, X-ray, boundary scan, flying probe, in-circuit test, cable test, and functional test. By bringing TestWay into the Siemens ecosystem, Siemens strengthens an already mature end-to-end approach, connecting PCB design, manufacturability verification, and downstream test engineering more seamlessly than ever before. This allows our customers to release more reliable products faster, without adding complexity to their toolchain.

This move will expand Siemens’ electronic systems design portfolio with best-in-class DFT expertise and elevate test readiness as a first-class part of the shift-left digital thread. The acquisition of ASTER Technologies strengthens the digital thread by connecting design intent, manufacturing constraints, and test strategy in a more continuous, bidirectional workflow, so insights from manufacturing and test can inform design decisions earlier and more consistently. The result is higher confidence through ramp and production, with fewer late-stage surprises and less friction across the design-to-manufacturing handoff.

Strengthening design for manufacturing across our industry

As products become more compact and supply chains more complex, the cost of late-stage discovery keeps rising. A holistic DFM solution, which uses digital verification to catch issues while these issues are still inexpensive and before manufacturing decisions become locked in is a key tenet within Siemens’ Valor portfolio.

A robust DFM solution contains design for fabrication, design for assembly and design for test solutions.

Product testing is no longer a downstream activity; it’s a business-critical discipline that must be planned early, engineered intentionally, and continuously validated.

A comprehensive test engineering strategy is an important component of a robust shift-left ideology. By embedding test intent early within design, we enable our users to intercept defects before they become respins, prevent product returns, and reduce costly field failures.

TestWay brings DFT into a shift-left workflow

DFT delivers value by shifting your testability and coverage left into the design, creating an engineered and measurable workflow strategy, rather than a late-stage checklist.

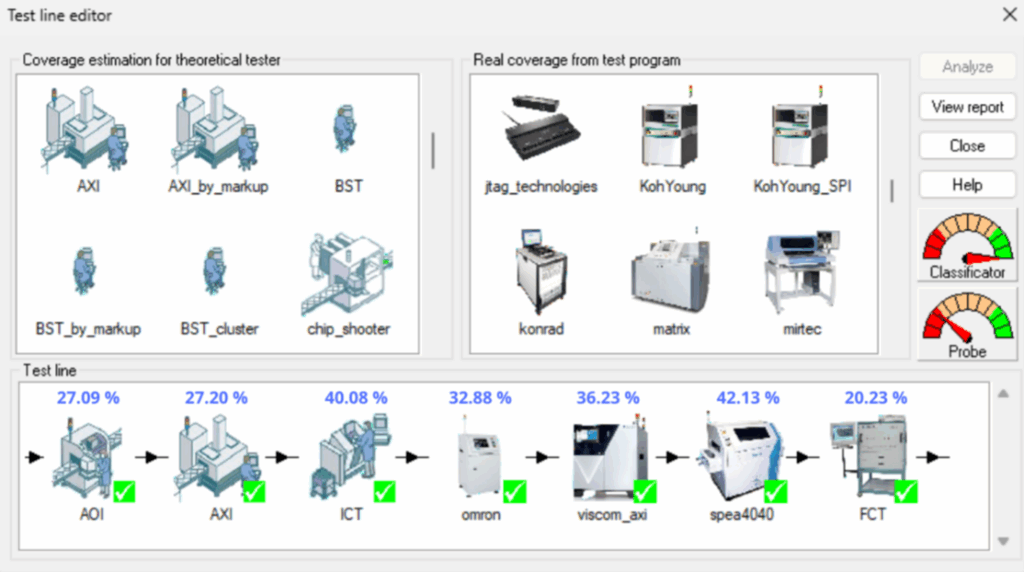

Implementing TestWay extends your digital thread beyond coverage, into operational performance. It can evaluate multiple test scenarios and models to determine your overall test coverage, allowing teams to tune their strategy based on the production process and the defects most likely to occur. Once that is complete, it develops the test machine input files required to perform the actual procedure, interfacing with more than 75 test and inspection machines. After the test program runs on the test line, the software measures actual coverage across more than 85 test and inspection machines, identifies gaps versus estimated figures, and enables closed-loop operation for maximum PCB coverage.

ASTER Technologies’ TestWay™ creates end-to-end test flows within a simple drag and drop interface by using a full mix of available inspection and test machines: SPI, AOI, AXI, boundary scan, ICT, flying probe, and functional test.

Siemens already brings manufacturing readiness into the PCB design process through mature DFM capabilities. TestWay strengthens that flow by adding DFT and coverage-driven test planning as a first-class part of manufacturability, enabling organizations to make earlier, more informed tradeoffs between inspection, probing, and downstream test approaches. It also supports a governance model that executives care about: consistent measurement and accountability.

Optimizing for yield

Yield is the most visible scoreboard for DFM because it reflects how well design intent survives the realities of fabrication and assembly at scale. Small choices in footprints, tolerances, stackups, accessibility, and process assumptions can accumulate into scrap, rework, delays, and margin erosion. In a strong shift-left DFM approach, yield is treated as a design outcome that can be influenced early through continuous verification and manufacturing-aware decisions that reduce sensitivity to variation and prevent defects from being designed in.

DFT complements this by ensuring that when defects do occur in complex electronics, they are detected quickly, localized accurately, and prevented from escaping downstream. By planning coverage across inspection and test stages and aligning that strategy to real accessibility and manufacturing constraints, DFT helps raise first-pass yield, lower escape rates, shorten debug cycles, and stabilize ramp so yield improvement becomes repeatable instead of reactive.

A warm welcome

Through the acquisition of ASTER Technologies, Siemens EDA strengthens your shift-left strategy by extending manufacturability thinking beyond fabrication and assembly readiness into testability and coverage planning, allowing early decisions which influence your design decisions when changes are still fast and affordable. In a world where electronics complexity is accelerating and quality expectations are unforgiving, DFM is a core business discipline that protects schedule, cost, and brand reputation by preventing respins and improving first-pass success.

With ASTER Technologies’ TestWay capabilities added to Siemens’ broader PCB portfolio, customers can pursue a more continuous, digital-thread workflow that connects design intent to manufacturing and test execution, helping teams validate earlier, collaborate more effectively across engineering and manufacturing, and deliver higher reliability at scale.