What’s new in Valor NPI 2504

The latest Valor NPI 2504 release delivers powerful enhancements that make your Design for Manufacturing (DFM) analysis faster, more intelligent, and better aligned with modern fabrication processes. This update expands the Analysis Definition Manager (ADM) with new, advanced constraint factors, particularly for rigid-flex designs, trench via analysis, and automated component spacing. For more details on the enhancements, you can refer to the Valor NPI 2504 release highlights document on Support Center.

In addition to the three core feature enhancements explored below, this release also includes:

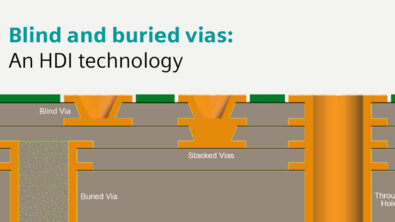

- Better performance across HDI and microvia checks

- Improvements for users running Japanese and Chinese operating systems

- Enhanced Cadence Allegro support

The release focuses on three main enhancements:

Component spacing based on source geometry

Valor NPI has made sweeping improvements in its handling of component spacing restraints. Prior to 2504, Valor NPI could only apply either VPL-based or EDA-based component spacing rules—not both. This led to false violations when the package source wasn’t uniformly covered by VPL data. With 2504, Valor NPI now supports automated component-to-component spacing logic which dynamically adjusts based on each component’s source geometry.

VPL to VPL – > VPL based spacing requirement

VPL to EDA – > EDA based spacing requirement

EDA to EDA – > EDA based spacing requirement

These additions will greatly reduce false spacing calls during DFM analysis.

Enhanced rigid-flex constraint handling

In response to the increasing complexity of rigid-flex PCB designs, Valor NPI 2504 introduces 11 new rigid-flex constraints along with three major new constraint factors:

- FPC Region Factor: Allows different rules to apply in flex vs. rigid regions

- Stiffener Technology Factor: Adjusts constraint behavior based on stiffener material (e.g., FR4, metal)

- FPC Copper Type Factor: Enables distinct rule sets for rigid vs. flex copper types

Additional updates include the support for positive coverlay representation, making it easier to visualize and analyze coverlay layers in ADM.

Trench Via Analysis

Linear trench vias are a growing trend in advanced PCB designs, offering benefits like reduced DC resistance, localized ground shielding, thermal dissipation, and structural reinforcement. Valor NPI 2504 introduces dedicated support for trench via technology, including seven new construction and spacing checks:

- Illegal or acute trench angles

- Improper trench-to-via spacing (same or different net)

- Endpoint gap in Linear Trench Via

- Duplicated holes within trench vias

Ready to Try Valor NPI 2504?

These enhancements reflect our continued commitment to improving a true Manufacturing Driven Design software offering. The improvements to our DFM intelligence further aligns our digital twin analysis with the ever changing and evolving real-world fabrication practices. Whether you’re preparing a complex rigid-flex layout, optimizing component placement, or adopting advanced trench via structures, Valor NPI continues to give you the power to validate and optimize your designs with confidence, while reducing your overall design cycle.

Check out the videos above to see these features in action and explore how the new Valor NPI 2504 can upgrade your workflow.

Explore Valor NPI with our Online Trial

Explore Valor NPI with our free online trial and find out how easy it is to implement the world’s most advanced DFM software. With no download or installation necessary, this simple guided tour provides immediate hands-on experience to the newest features available.

Select your desired workflow: