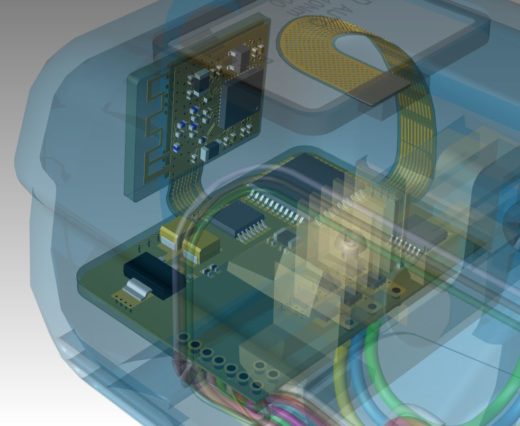

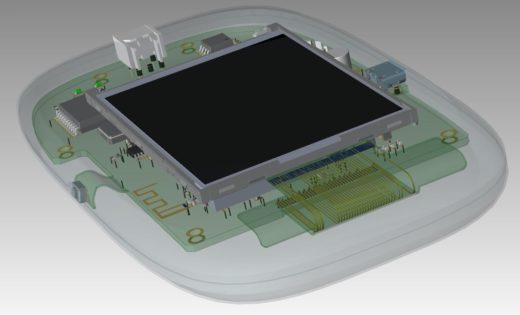

Should you consider using rigid-flex technology?

Electronic design is ever-changing to adapt with demand. The industry is currently shifting to incorporate more rigid-flex circuits as the preferred interconnect technology for items that would otherwise be off-board, or require a smaller form factor. Industries like IoT, wearables, communications, automotive, and medical are all being challenged to make products smaller, more reliable, and cheaper. The solution to solve these design issues is rigid-flex! In fact, the global demand for the flexible electronics is expected to generate revenue of $16.5B by 2021 and grow more than 21% between 2016 and 2021.

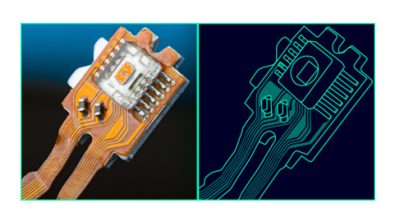

Why have you or so many other companies avoided this technology? Because it’s an unknown, due to the lack of experience and tool requirements needed to create the special features associated with flex design. Historically, companies have used mechanical tools that have zero intelligence for electrical elements. This leads to time wasted doing extensive design reviews or producing multiple prototypes to get it right. Electrical designers have tried using PCB tools, which provides some intelligence for DRCs, and eases the trace and plane routing. However, most tools don’t have the special features required to properly design a flex.

So, what are the special design features required for flex design?

PADS® Professional stands apart from every other electrical engineering tool, because it provides all the technology required to design a flex and rigid-flex product. Designing with the confidence – knowing you don’t have to deal with work-arounds or produce multiple prototypes to ensure you’ll have a highly reliable product – is what you’ll get with PAD Professional flex technology.