Siemens Capital integrations drive smarter electromechanical design

Capital integrations enable seamless collaboration between electrical and mechanical design teams by connecting workflows.

Now more than ever, building modern products requires tighter collaboration between cross-domain teams. As systems grow more sophisticated and development cycles shrink, siloed processes and manual data exchanges are increasingly risky and can cause delays in production. There’s no getting around it – integrated design workflows are essential to keep pace with design complexity and market demand.

By connecting Capital for electrical system design with tools such as NX for mechanical design through Teamcenter’s powerful lifecycle management, Siemens delivers a unified environment that enables true electromechanical codesign. This integrated approach helps teams move faster, reduce rework and build smarter, higher-quality products.

In this blog, we explore the current integration capabilities of Capital and NX, and the tools and workflows that make this ecosystem so powerful and effective in real-world use cases.

Capital integrations and a complete product context for electrical design

Integration between Capital and the product lifecycle management (PLM) tool Teamcenter empowers electrical engineers to design with full awareness of the product’s broader context. How? By connecting data, processes, and people across disciplines.

Orchestrated Workflows

Siemens Teamcenter acts as the digital backbone for Capital, managing electrical design data and lifecycle activities within the broader product development process.

With Teamcenter, Capital users can better initiate, track, and complete engineering changes through standardized processes, ensuring full traceability and governance throughout the product lifecycle.

With orchestration, changes aren’t managed in isolation. Instead, they’re integrated into enterprise-level workflows that connect mechanical, electrical, and software teams. This integration improves cross-functional visibility, eliminates delays, and simplifies compliance with product and regulatory requirements.

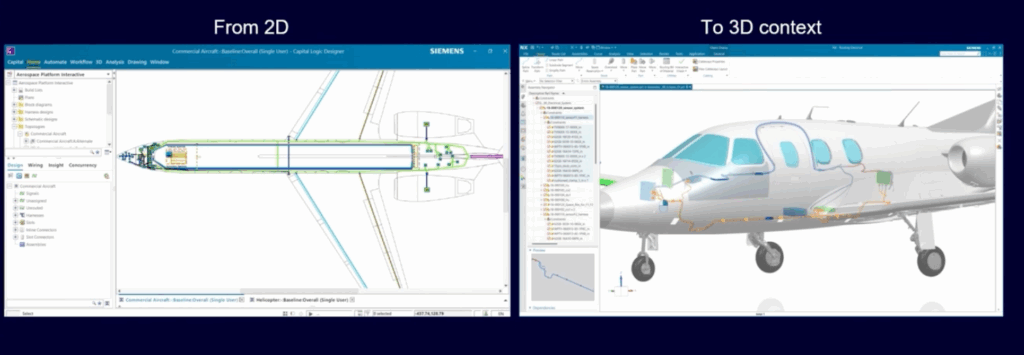

NX and Capital: Real-time design

The integration of Siemens Capital with NX is what will bring real-time electromechanical collaboration to life. Electrical and mechanical teams can work together in a shared 3D environment, eliminating delays and errors that can stem from siloed workflows and manual data handoffs.

Bi-directional data exchange

Electrical designs created in Capital can be transferred into NX through Teamcenter, ensuring that mechanical and electrical teams are always working from the same, up-to-date information. At the same time, mechanical context such as 3D geometry, spatial constraints, and component placement flows back into Capital.

This mutual exchange of data enables electrical designers to make informed decisions based on physical constraints, reducing the likelihood of routing errors or late-stage rework.

Support for advanced design constraints

Integrations are especially beneficial for industries like aerospace and electric vehicles, where design margins are tight and requirements for signal integrity and redundancy are stringent. The combined environment allows engineers to simulate the real-world behavior of wiring harnesses directly in context—catching issues such as proximity violations or excessive lengths early in the development cycle. With NX and Capital working together, teams can validate and optimize their designs before building a single physical prototype.

Flexibility is a key characteristic of the integration. Some teams prefer high-frequency updates that reflect changes in real time, while others require more deliberate control, choosing to synchronize only at key milestones or through defined release gates. Siemens enables teams to synchronize design data at a pace that aligns with their specific workflows.

This flexibility is underpinned by centralized Bill of Materials (BOM) and product configuration management. Regardless of how often data is updated, electrical, mechanical, and systems-level views always stay in sync. That consistency enables effective design authoring, validation, and change tracking throughout the development lifecycle, reducing the risk of misalignment.

Powering the future of integrated product design

Capital integrations deliver a truly unified platform for end-to-end electromechanical design. By supporting live 3D routing, real-time synchronization, cross-domain BOM alignment, and configurable workflows, Siemens helps engineering teams break down silos and collaborate with unmatched efficiency.

Capital’s integration with NX empowers users to validate decisions earlier, reduce manual errors, and accelerate design cycles without sacrificing precision or control. With Capital, NX, and Teamcenter working as one, organizations can build a foundation for smarter innovation, and sustainable growth.

Read our first blog related to the topic of integrations here: The origins and impact of Siemens Capital integrations

Watch the full recording of our presentation at Realize Live, Evolution of Capital integrations into the Siemens Xcelerator ecosystem.

Capital X is the SaaS (Software-as-a-Service) version of the Capital portfolio that has been the leading solution for comprehensive E/E systems development for over two decades. Capital X, operated by Siemens, offering a comprehensive digital twin and seamless collaboration to optimize the design, engineering and validation of complex products. Click here to learn more about Capital X.