Formboard design and the digital twin approach

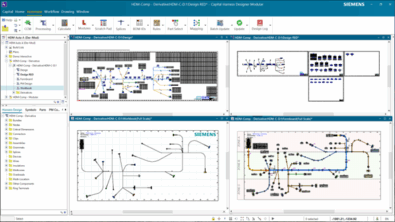

Formboard design drawings are one-to-one, full-scale representations of wiring harness design data, enriched with additional manufacturing information. It gives a view of the wire harness design data as a digital twin.

Along with the wire harness objects, all manufacturing-relevant objects like bundle forks, connector holders, clip holders or tape position indicators are graphically represented on these formboard models. Formboards provide visual aids for the operators that guide them during harness assembly.

The success of harness manufacturers is dependent upon their ability to accurately design, optimize and cost the manufacturing processes, labor, material, and resources required to produce harnesses. Capital contributes to an optimized digital twin comprising a validated harness model and a digitalized manufacturing process model. This can be leveraged to transform a company’s engineering, costing, and manufacturing performance ultimately boosting profits.

A digital twin is an exact, virtual representation of a product or process used to virtually validate the performance of its physical counterpart.

– Learn more about digital twins

So how can a comprehensive E/E systems development solution enable a digital twin approach to creating a formboard? Well, Capital can guide formboard designers to create optimized, ergonomic layouts based on dynamic feedback of labor effort or times related to each component, as it is placed in a particular zone on the board. Designers can also create and maintain merged or combined formboards for efficient production lines and factory space usage.

Capital is an example of a comprehensive E/E systems development solution that can be used for formboard design. It covers the design, manufacture and service of electrical systems as well as encompassing E/E system and software architectures, network communications and embedded software development.

This software enables you to:

- Create a full-scale view of the existing design data in a formboard diagram.

- Adjust the formboard for the best ergonomic layout using live metrics and analysis.

- Easily manipulate bundles to fit the harness to the board, honoring minimum bend radius and other constraints.

- Automatically place fixtures in the correct location using automatic rules and constraints.

- Merge or combine multiple formboards to maximize manufacturing efficiency.

Explore more about formboard design on our glossary page here.

Research how Capital products, such as Formboard Designer, can take on your wiring harness needs.

View our on demand webinar on the growing need for digitalization in the harness industry and see how Siemens’ advanced harness design and manufacturing engineering solutions help companies transform challenges into competitive advantages.