How to catch up with shrinking automotive cycle times

The average consumer is surrounded by gadgets. It’s rare to find someone who doesn’t have a smart phone in their pocket, a notebook (or laptop) computer under their arm, or a smart watch strapped to their wrist. Every release of a new smartphone, tablet or other device is accompanied by a mad rush of customers hoping to obtain the latest and greatest in features, functionality and design. Device manufacturers, of course, constantly aim to satisfy these demands for cutting edge features. The result is a general reduction in the lifecycle of consumer electronics. For example, the average consumer upgrades their mobile phone every 29 months.

Recently, this trend has begun to creep into the automotive world. Automotive customers expect a greater number of built-in vehicle features and better connectivity with their other devices. For some, the availability of advanced features like driver assistance systems and smartphone connectivity is the driving factor in their car-buying decisions.

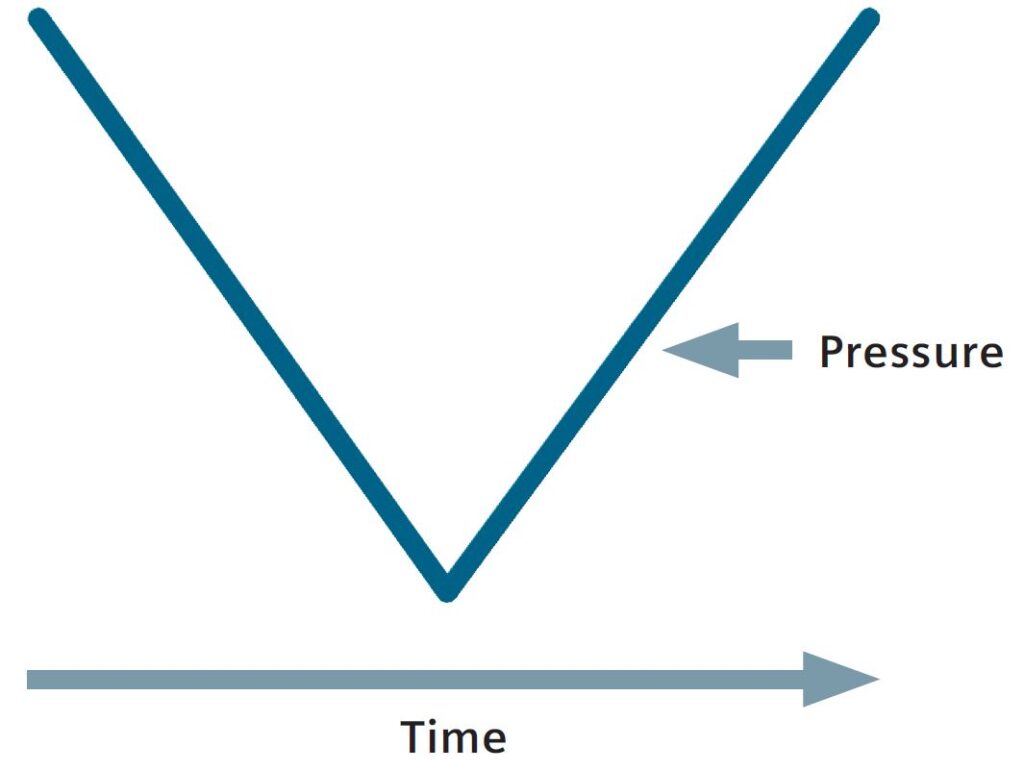

The growing consumerization of the car is pressuring carmakers to maintain shorter, more flexible design cycles. This is problematic for design teams using the traditional approach to the engineering ‘V-cycle’, usually composed of disconnected processes that make it especially difficult to respond to quick changes. There is already a pipeline full of new technologies and advanced features that are being readied for deployment into the automotive market. The market pressures described above will drive further pressure on this pipeline to get it done faster (figure 1). How does an OEM ensure that their engineers can safely and cheaply deploy the features in this pipeline as quickly as possible? As I see it, a fundamentally different approach to engineering is required.

cycles, squeeze the ideal System V flow.

What’s needed is a controlled and seamless flow of data across departments, automation, and abstraction of requirements such as auditing changes and modeling new functionality, both in terms of correctness and cost. And ideally, design tools should link all the way to the creation of service documentation, a major challenge given the exploding number of vehicle configurations. The main task, then, in this new connected-car era is building more flexible design flows that are better at adapting to changes in customer preferences.

For example, a tool suite that manages user data without any manual transfers preserves data integrity, prevents errors and resolves a critical failure point common to traditional engineering processes. When the System V is strengthened by such a coherent tool and method, it will more easily shrink under the market pressure while maintaining solid engineering integrity. To read more about how advanced engineering software, such as Capital from the Xcelerator portfolio, can help companies shrink their development times, please read our whitepaper, V-cycle strains as cars morph into consumer gadgets.

You might also be interested in:

- E/E systems development with Capital short video

- Blog post: Re-imagining electrical systems design

- On-demand webinar: EDS Design in the MBSE Digital Thread