Unlocking digital transformation in CPG: Steering the future of innovative personalized products

Digital transformation in the Consumer Packaged Goods (CPG) industry is at the forefront of innovation, addressing the rising demand for products tailored to individual health preferences, lifestyles, and environmental awareness. This transformation marks a significant move towards personalized consumer experiences, urging CPG manufacturers to evolve their approach to product design, development, and delivery.

The evolution of consumer expectations in CPG

Today’s consumers are at the forefront of a transformative shift in the Consumer Packaged Goods (CPG) industry, driven by their desires for products that not only meet their unique needs but also reflect their personal values. No longer passive buyers, consumers have become active co-creators, seeking out and even demanding that companies provide personalized consumer products. This shift is rooted in several key consumer values:

- Health and Wellness: There’s a growing demand for products that support a healthy lifestyle, whether through specific dietary needs, skin care regimens, or overall wellness.

- Environmental Stewardship: Consumers are increasingly aware of their ecological footprint, favoring products that are sustainably sourced and produced with minimal impact on the environment.

- Individuality: In a world saturated with generic, mass-produced items, the desire for distinctiveness has never been stronger. Consumers seek products that allow them to express their unique identities.

This profound change in consumer behavior underscores a larger trend towards personalized consumerism. The marketplace is vibrant and dynamic, offering an array of choices that cater to individual lifestyles, health preferences, and environmental concerns. The era of “one-size-fits-all” products has given way to an era where customization and personalization reign supreme, signaling a permanent shift in how products are designed, marketed, and consumed.

As the CPG industry navigates this new consumer paradigm, the role of digital transformation becomes increasingly crucial. By leveraging innovative technologies, companies can meet these evolving expectations, delivering personalized, compliant, and environmentally friendly products that resonate with today’s consumers.

Bridging the gap: challenges in the path of customization

Despite the clear demand for personalized products, manufacturers face significant hurdles:

- Regulatory Rigor: The CPG industry, especially cosmetics, is tightly regulated, with product safety and compliance at the forefront. Navigating these regulations while innovating poses a substantial challenge.

- Production Paradox: Achieving the level of customization demanded by consumers while maintaining the efficiency and cost-effectiveness of mass production is a complex balancing act.

- Time to Market: In a fast-paced market, the ability to swiftly move from concept to shelf is critical. However, the intricate requirements of personalized consumer products can slow down this process.

Ensuring excellence through CPG quality control

Central to achieving product excellence amid the demand for rapid customization is Opcenter RD&L (Research, Development & Laboratory), a holistic platform that seamlessly integrates laboratory information management systems (LIMS) functionalities, driving innovation efficiency and robust data management for the CPG industry.

- Integrated Research, Development, and Quality Assurance: Opcenter RD&L embodies a comprehensive approach to product development, merging research, development, and laboratory capabilities into a cohesive platform. This integration allows for a streamlined product development cycle, from initial concept through to quality assurance, ensuring each product reaches the market with the highest standards of quality and compliance.

- Centralized Data Management and Process Efficiency: With components like Opcenter Specification and Opcenter Formulation, Opcenter RD&L offers a central repository for raw materials, semi-finished and finished goods, and packaging materials, alongside advanced formulation capabilities. This not only optimizes the management of bill of materials (BOM) and document version control but also enables the virtual development of improved formulas, reducing reliance on physical trials and accelerating innovation.

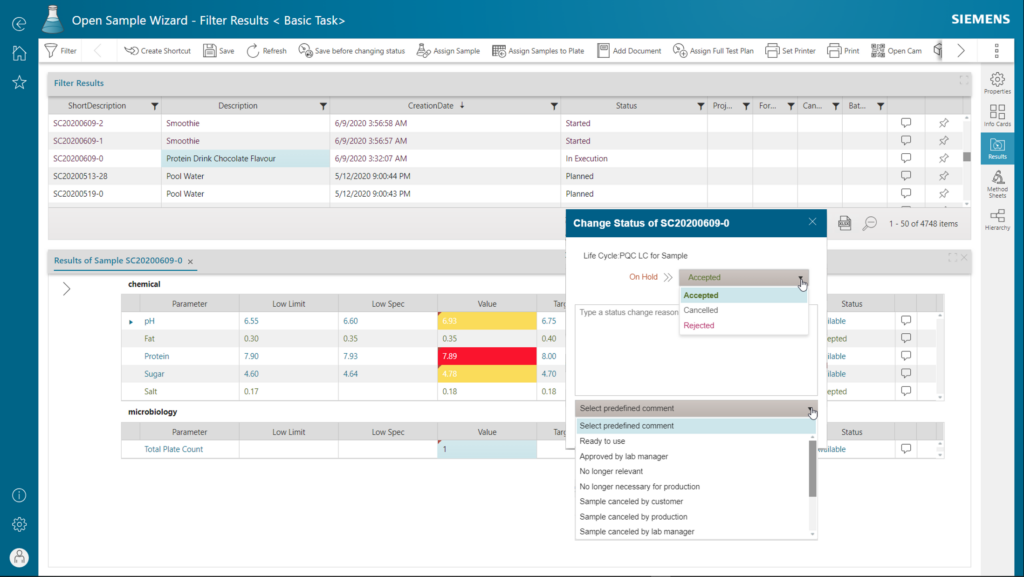

- Laboratory Throughput and Product Quality: Opcenter Laboratory, as an integral part of Opcenter RD&L, enhances laboratory throughput and efficiency in quality test execution. This ensures premium product quality from early formula development onwards, embedding a culture of excellence and precision throughout the product lifecycle.

Achieving efficiency in product development: The role of integrated digital solutions

The integrated capabilities of Opcenter RD&L, encompassing both R&D and LIMS functionalities, highlight the platform’s role in facilitating digital transformation within the CPG industry. This holistic solution not only streamlines innovation processes but also ensures a steadfast commitment to quality, safety, and compliance.

Opcenter RD&L: Pioneering formulated product design

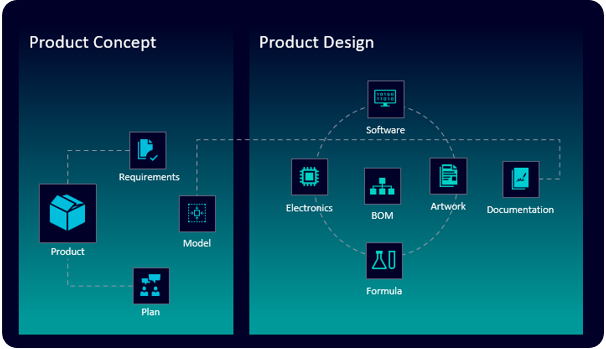

Opcenter RD&L stands as a comprehensive suite for:

- Comprehensive Digital Twin Technology: Leveraging Opcenter Formulation, this component enables the simulation and detailed assessment of formulas, significantly reducing the reliance on physical trials. By facilitating virtual experimentation, it accelerates the formulation and validation of new products, embodying the essence of digital twin technology in the CPG industry.

- Streamlined Research & Development: Through Opcenter Specification, the suite offers a central repository for up-to-date data on raw materials, semi-finished and finished goods, and packaging materials, including bill of materials (BOM) and document management with version control. This ensures a streamlined workflow from concept to final product, enhancing efficiency and innovation.

- Modular and Adaptable Platform: Tailored to meet the dynamic needs of the CPG industry, from cosmetics formulation to product design, Opcenter RD&L’s flexibility supports a wide range of product development initiatives, showcasing its adaptability across various sectors.

LIMS: Enhancing quality and compliance

Integrated within the Opcenter RD&L ecosystem, Opcenter Laboratory is a full-scale laboratory information management system (LIMS) that:

- Enhances Laboratory Throughput and Product Quality: It raises lab throughput and efficiency in quality test execution, ensuring premium product quality from early formula development onwards. This integration embeds a culture of excellence and precision throughout the product lifecycle.

- Facilitates Collaborative and Efficient R&D Support: By integrating quality by design principles, it accelerates innovation while embedding compliance and quality into every product, reflecting the seamless synergy between R&D efforts and quality assurance.

- Enables Lab Automation and Efficiency: Through automation and direct instrument integration, this component boosts laboratory productivity, accelerating the pace of innovation and compliance, ensuring products meet the highest standards of quality and regulatory adherence.

By harnessing the integrated strengths of Opcenter Specification, Opcenter Formulation, and Opcenter Laboratory within the Opcenter RD&L suite, manufacturers are equipped to navigate the complexities of product development in the CPG sector efficiently. This holistic approach not only streamlines the innovation process but also reinforces the commitment to quality, safety, and compliance, leading towards a future where efficiency and customization converge.

The competitive edge of integration

The seamless integration of R&D and manufacturing processes, facilitated by Opcenter RD&L, ensures that all elements—from formula to packaging—remain aligned, optimizing the product lifecycle and ensuring compliance. This strategic coherence not only accelerates time-to-market but also fortifies manufacturers against the risks associated with product recalls, safeguarding brand reputation and consumer trust.

Forward-thinking: Embracing digital transformation in CPG

In the journey from imagination to creation within the CPG industry, digitalization, championed by the comprehensive capabilities of Opcenter RD&L, is redefining what’s possible. Manufacturers equipped with this integrated suite are at the forefront of the transformation, delivering personalized, compliant, and environmentally friendly products. As the industry moves towards a future where products are increasingly tailored to individual preferences, the role of such integrated digital solutions becomes ever more pivotal in bridging the gap between aspiration and realization.

Want to learn more?