Tackling automotive complexity with model-based systems engineering

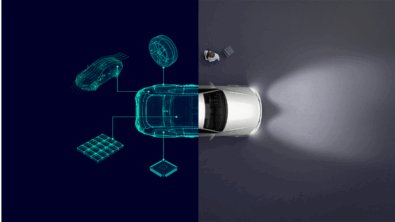

The modern vehicle is no longer just a machine — it’s a software-defined, highly complex system of systems. Between the rise of electrification, advanced driver-assistance systems (ADAS) and increased demand for software-based features, automotive OEMs face an increasingly difficult task: how to keep up with complexity while accelerating delivery and maintaining safety, performance and compliance.

What’s needed is a shift in development processes. Automakers must bring together software, electrical and mechanical engineering earlier in the lifecycle and maintain alignment as the vehicle evolves. That’s where model-based, multi-domain system development comes into play — enabling engineering teams to frontload decisions, validate designs continuously and reduce costly late-stage changes.

Let’s look at how this approach comes to life across three key engineering domains.

Start with the system: modeling the architecture upfront

As the complexity of vehicles increases, so does the need for a robust system architecture that acts as a source of truth across all engineering disciplines. This means defining system needs, boundaries and behaviors at the earliest stages — and making sure those definitions are maintained and referenced throughout development.

By using model-based systems engineering (MBSE), OEMs can capture product requirements and constraints within a shared architectural model. This improves traceability, supports reuse across programs and helps engineering teams explore architectural options that account for future features and software monetization strategies, not just today’s requirements.

This integrated methodology enables companies to define and evolve a system’s architecture with traceable links to software, electrical and mechanical domains — accelerating development and improving cross-discipline collaboration.

Building in performance from the beginning

With software-driven features shaping the customer experience, it’s critical to assess how architectural choices impact performance from the start. That means simulating interactions between systems and subsystems — and doing it continuously as the design evolves.

Simulation-led design enables engineering teams to explore trade-offs like weight, cost, energy efficiency and thermal behavior in a virtual environment. The result? Smarter decisions earlier in development, fewer surprises later, and a reduction in costly physical prototypes.

By combining 1D simulation, 3D CAE, and test capabilities, performance engineering helps validate behavior across domains — from vehicle dynamics to energy consumption — to ensure that real-world performance meets expectations.

Coordinating software across the lifecycle

In the shift toward software-defined vehicles, software is no longer a late-stage add-on, but an integral part of the system architecture. But software development must also evolve to match the pace and complexity of modern programs.

That’s where application lifecycle management (ALM) plays a key role. With a unified approach to requirements, change management, testing and release, teams can ensure software aligns with both system-level goals and hardware constraints. And with variant management built in, it’s easier to support growing product portfolios without adding complexity.

A process-neutral, integrated solution that connects all aspects of software development — including variation management — while enabling seamless integration with PLM and other systems.

From theory to the road: how Nissan put this into action

To meet new customer expectations and technology demands, Nissan recognized that its legacy V-model development process was no longer enough. The company needed a more iterative, cross-domain approach — one that could enable teams to explore architectural alternatives, assess safety risks earlier and ensure seamless integration of new features.

By adopting a model-based methodology and aligning teams around a shared system architecture, Nissan accelerated development timelines, improved traceability and gained the ability to respond to changes with confidence.

Case study: Nissan accelerates software and systems innovation with model-based development

Nissan’s approach resulted in:

- Earlier identification and mitigation of integration risks

- Reduced development lead time

- Improved collaboration across software, electrical and mechanical teams

Closing thoughts on model-based systems engineering

The automotive industry is evolving fast, and the complexity isn’t slowing down. But by frontloading system modeling, aligning software and hardware development and continuously simulating performance, OEMs can keep pace with change while reducing risk and cost. Multi-domain system development isn’t just a strategy for surviving complexity — it’s a foundation for driving innovation.