The Correlation Between Safety Tool Chains and Nuclear Disarmament

The title may have you wondering how the heck I’m going to tie together two very disparate topics. Well here goes! As most are aware, there has been significant growth in safety critical markets with automotive being the recent front runner. To support the advancement in features and technology, tool companies have been rapidly developing solutions to assist and even automate aspects of the safety lifecycle. This includes tools to aid early cycle activities such as requirements definition as well as tools deployed later in the lifecycle that automate the insertion of safety mechanisms and execution of a fault campaign.

With each passing quarter, new technologies and features are released to help engineers execute activities and visualize issues that arise throughout the lifecycle. Tool companies offering point solutions to assist engineers at each phase, providing integration of these point solutions into a holistic workflow, and enable easier interoperability across the supply chain will be well positioned to drive the development of next generation products.

As new solutions fill gaps and existing solutions are enhanced to meet today’s challenges, I often wonder how automated the safety lifecycle will become? Specifically:

- Will the industry tolerate full automation of certain safety activities? And if so, which ones?

- Where can automation be leveraged to assist safety experts?

- Which activities will remain driven entirely by a safety expert?

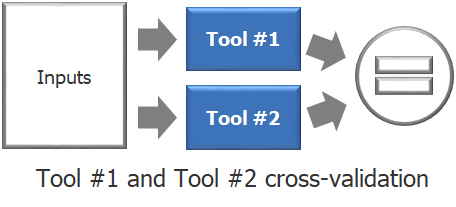

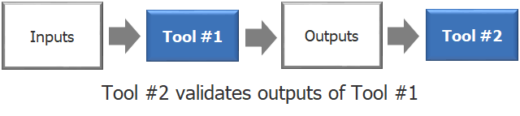

One of the challenges facing safety teams wanting to incorporate automation into their safety lifecycle is trusting tools to deliver correct results. As I contemplated this, the following phrase popped in my head: “Trust, but verify”. Back during the cold war, this phrase drove the framework in verifying the nuclear disarmament between the former USSR and the United States. This phrase was also leveraged within the context of compilers and checks performed at compile versus runtime. New solutions will enter the market and existing solutions will grow in maturity, but no tool is perfect, and therefore, it is critical to review the data to ensure accuracy of results. Fortunately, tools can offer assistance in this space as well. A tool chain, when properly constructed, form a set of checks and balances where the accuracy of results from one solution are validated with another solution This is a concept known as independent tool assessment across multiple safety critical industries. By leveraging tools to perform the “but verify” activity, reoccurring and engineer driven tool checks can be reduced, saving significant time and resources. Figure – 1 and Figure-2 below demonstrates this concept.

Figure -1 – Independent tools cross-checking results

Figure -2 Downstream tool checking upstream tool results

I believe there is the need for the safety engineer, especially in the concept and architecture phases where understanding of intent, use model, and definition of the safety concept are required. However, there are and will continue to be opportunities for greater levels of automation, especially in later stages of the lifecycle. Perhaps with the proper tool chain in place, there is a path forward where infrastructure, tools, and methodology can safely automate larger pieces of the lifecycle.

Comments