Why is everyone suddenly interested in the supply chain?

Prior to the global pandemic, most people didn’t give the supply chain much thought. There was no reason to—consumers had become accustomed to a reality in which they could simply click on an item on a website, and it would magically arrive on their doorstep the next day. What difference did it make how it got there and where its components were produced as long as everything was running smoothly?

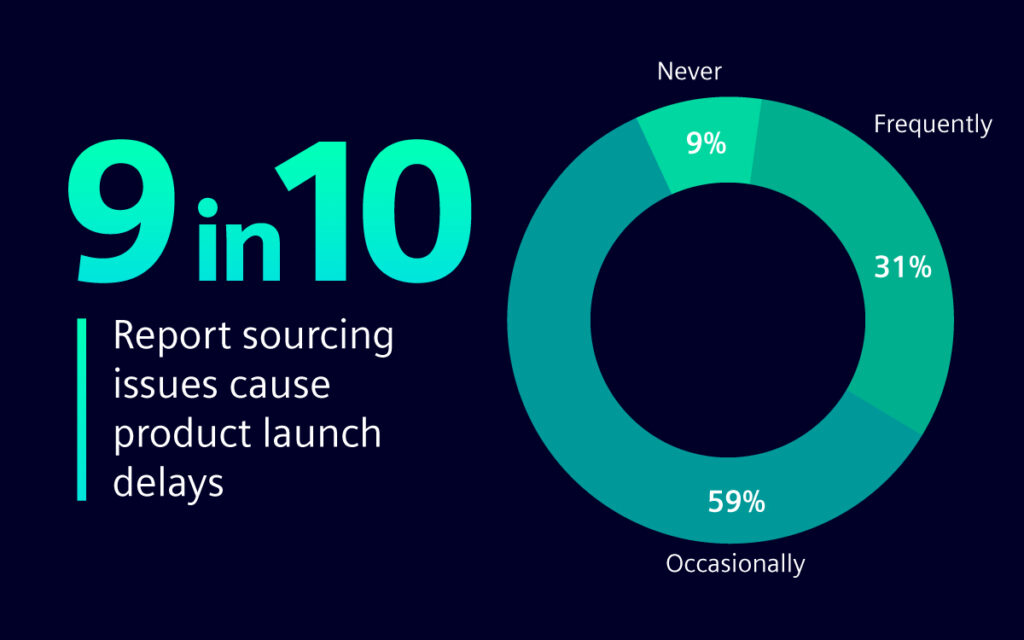

That reality has changed drastically in the past year and a half since the onset of the pandemic. Suddenly, it seems like there is a backlog of several months on every item, from cars to washing machines to books, and the supply chain has become the headline news in leading publications. What happened? Are the changes tied solely to COVID-19? Will things return to normal as we recover from the pandemic?

The challenges facing electronics manufacturers are compounded by the fact that they are competing with manufacturers of products as diverse as food, medicine, clothing, furniture, and cars for logistical resources, resources that have become increasingly scarce in the past year and a half. And that doesn’t even take into account extreme situations like when one of the world’s busiest shipping lanes was blocked for almost two weeks earlier this year. No industry is immune, not even electronics.

Let’s look at some of the key challenges facing the supply chain today.

Rising shipping costs and delays

One of the key enablers of globalization was inexpensive container shipping. Manufacturing facilities could be transferred from the US and Europe to Asia and other locations because it was fairly easy and inexpensive to ship the finished products all over the world. Before the onset of the pandemic, the average cost of shipping a container was $2,000 – $5,000. Today, shipping the same container often costs close to $30,000, and even then, there is no guarantee that it will arrive on time.

Air shipping has also been impacted. In the past, goods were often shipped in the storage compartment of passenger flights to save the costs of chartering an entire plane. With significantly fewer commercial passenger flights running during the pandemic, air shipping is also limited.

Acute shortage of raw materials and components

Whether products are manufactured overseas or locally, the raw materials used in their production often come from overseas. Given the delays in shipping, the entire world is currently experiencing acute shortages of critical raw materials like compounds used in medications, metals, and even the pulp used to manufacture paper. In a classic supply and demand scenario, the shortages in raw materials have led to a steep rise in prices that carries over to the components they are used to produce.

For example, in August 2021 the contract chipmaking giant Taiwan Semiconductor Manufacturing Co. announced that the prices of all their chips would be increased by as much 20%, and additional manufacturers are following suit. Manufacturers will be forced to either raise the prices of the final goods, a move that will likely lead to a loss in sales, or reduce their profit margins.

Manpower shortage and the Great Resignation

The supply chain today is driven by people. People mining and processing raw ingredients, people on the shop floor in manufacturing facilities, people loading and unloading shipping containers, and people driving the trucks that bring the goods to their final destination. Covid-19 in general, and the Delta variant in particular, have led to a huge shortage of manpower in all parts of the supply chain.

Most of the supply chain work can’t be done from home, and people have been either unable or unwilling to work in person during COVID-19 surges. Even when they are able to work, the number of workers who can be physically present at a given location at the same time is often limited. Workers who have family members at risk or have children learning at home have been leaving in-person work in unprecedented numbers in a phenomenon known as “The Great Resignation”. HR departments in companies all over the world are reporting extreme difficulties in recruitment. Even if they are able to recruit workers, the workers expect increased compensation to balance the risk of in-person work.

Just go to any major port and you’re likely to see tens or even hundreds of container ships waiting offshore because the ports simply don’t have the manpower to unload and process the ships at the desired pace. There aren’t enough truck drivers to pick up the containers and transport them to their final destination. Manpower is lacking at every step of the way.

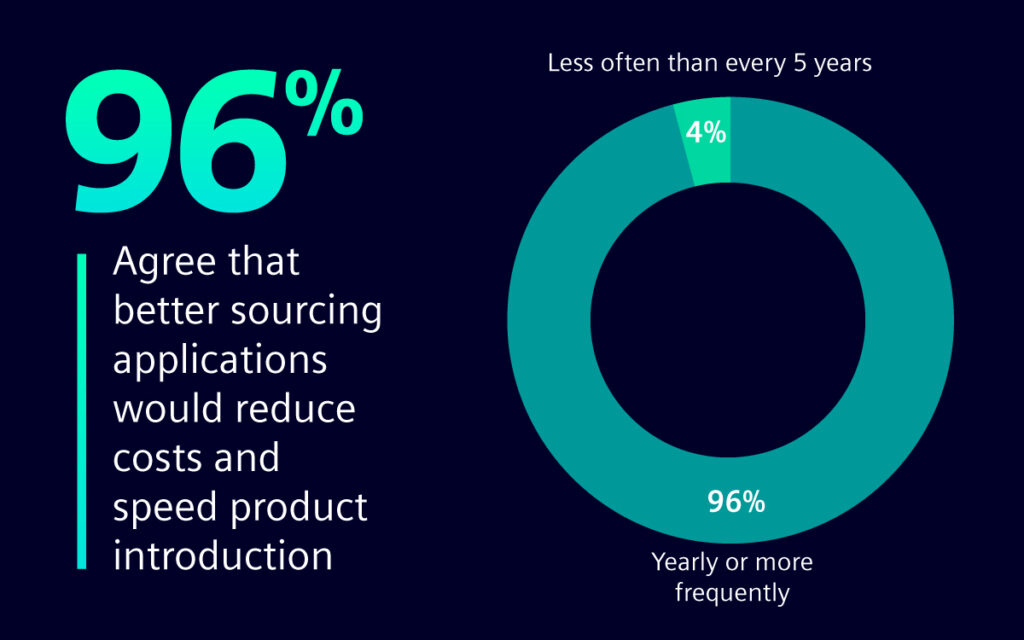

Overcoming the challenges and building supply chain resilience

These challenges have transformed smart supply chain management and automation from something “nice to have” to a burning need for most manufacturers. Manufacturers need real-time visibility of materials and every element of the manufacturing process in order to adapt to the changing landscape and build supply chain resilience.

The next articles in the series will address key strategies and tools for achieving that goal. Stay tuned!