Manufacturing Driven Design – Taking DFM to the Next Level

Max Clark, an industry veteran of over thirty years and currently Business Unit Manager at Siemens, recently published an e-book on how to take PCB DFM to the next level. It’s called Manufacturing Driven Design and can be downloaded from the I-connect website here.

Max started his career in the PCB fabrication industry and was one of the early employees of Valor, the pioneer in DFM. Through his experience in the industry, dealing with fabricators, contract manufacturers and OEMs, Max has learned how to bridge the manufacturing process knowledge between design and manufacturing to the benefit of all parties.

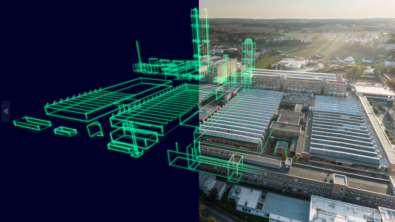

Manufacturing Driven Design (MDD) is an evolutionary approach to DFM. It enables the effortless exchange of manufacturing process constraints so that an OEM can assess the manufacturability of a design in perfect alignment with their suppliers. Previously, DFM was more of a post-layout process to make sure the design was manufacturable before it was released. However, the DFM rules were primarily setup through brute force and constituted a compromise on effort versus return. Furthermore, they often did not take into consideration the actual manufacturing processes that will be employed to build the PCB, leaving it to the discernment of the DFM engineer to determine if certain design aspects would cause a manufacturing issue.

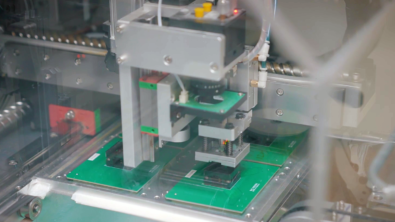

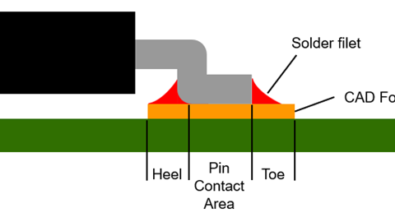

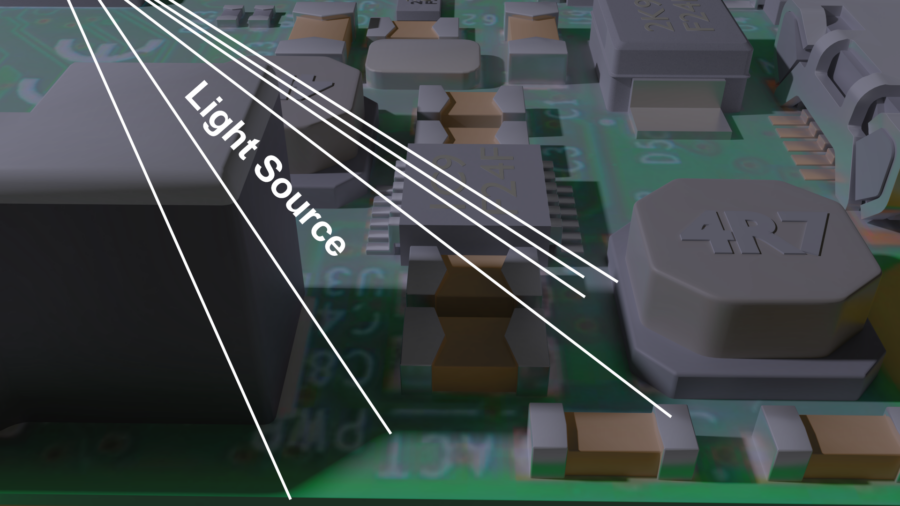

An example of this would be understanding how the board will be inspected. If the PCB will be inspected using Automated Optical Inspection (AOI) for the existence and correct location of solderjoints, the tall components on the design cannot be placed too close to adjacent leads, otherwise they will shadow the solderjoints to be inspected. CAD Design Rule Checks (DRCs) do not address this manufacturing issue. But without that knowledge, a designer may find themselves receiving a Technical Query (TQ) from their contract manufacturer asking them to either re-spin the design or waive the inspection of the affected solderjoints. Neither of those are good choices.

Having the manufacturing awareness built into the PCB design process through Manufacturing Driven Design, assures that each stage of the design is optimized for manufacturing yield, cost, and reliability before it moves to the next stage. The result is a PCB design that is released to manufacturing with full confidence without inefficient iterations.

Download the Manufacturing Driven Design e-book and learn how you can take DFM to the next level.