How Siemens and Nvidia bring AI to industry

Bringing AI into industry isn’t something that any single company can tackle alone, with different companies bringing different expertise to develop AI solutions. Developing an AI solution that can meet both the challenges and rigors of industry is no simple task and in a recent podcast, experts from Siemens and Nvidia talked about what it means to bring AI-powered solutions into industry and why these collaborations are so important in achieving that goal.

Check out the full episode here or find some highlights of that conversation below.

Collaboration accelerates adoption

Artificial intelligence has a lot to offer on the shop floor but with numerous technical challenges to overcome including access to compute resources, data collection and with nearly 40% of people believing it to be untrustworthy, adopting AI to the shop floor isn’t simple or straightforward. To achieve these goals, domain experts ranging from AI to compute and simulation to shop floor design and production must pool their skills to develop true industrial-grade AI solutions.

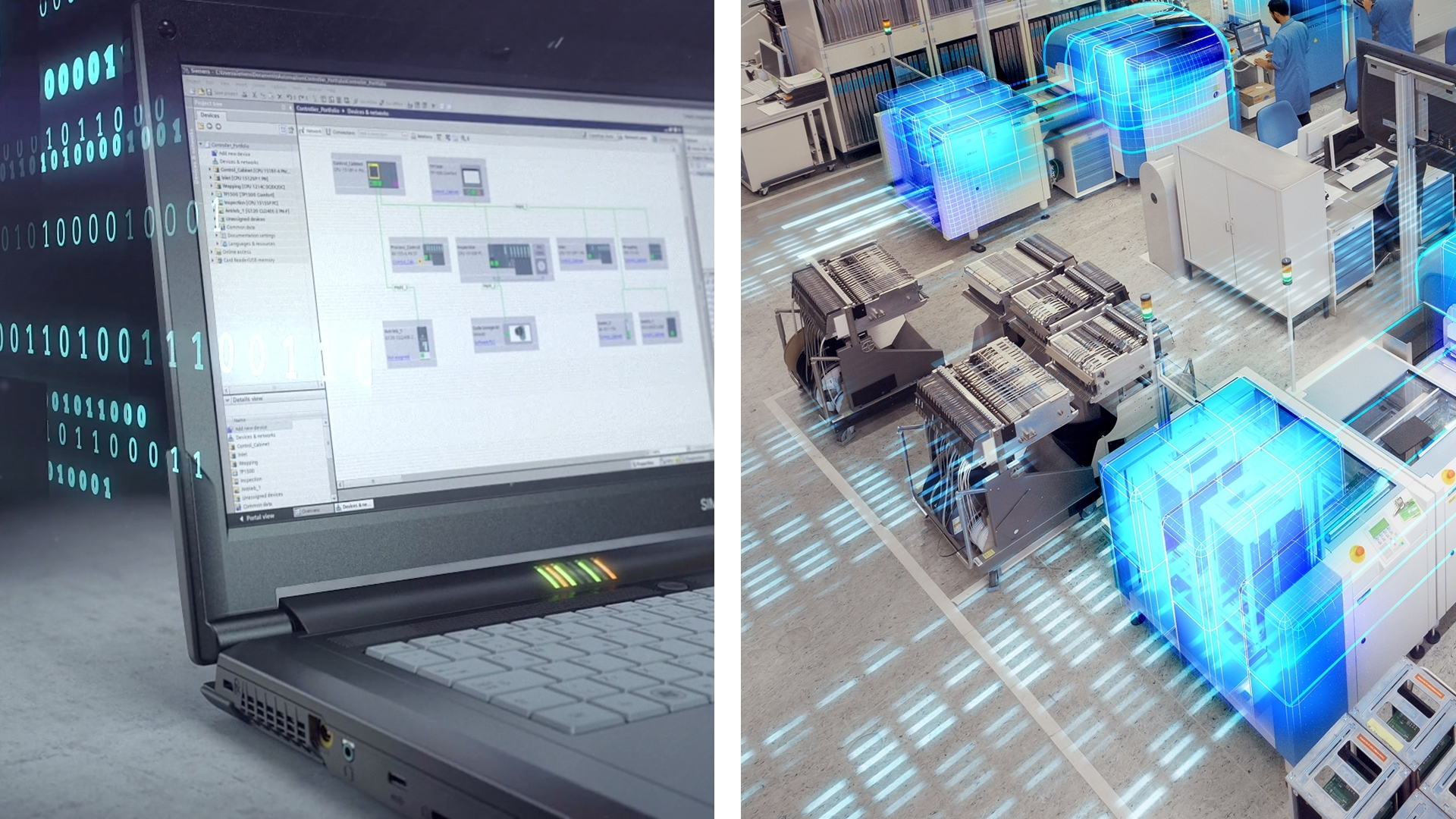

Siemens, with their extensive background in design, production and automation combined with Nvidia’s expertise in simulation, compute and AI is one such partnership that will help companies achieve their AI goals on the shop floor. With data playing a bigger and bigger role in both the design and manufacturing of products, combining Siemens comprehensive digital twin with Nvidia’s omniverse provides a stable backbone from which to expand AI offerings.

AI supercharges productivity

AI has the ability offer super powers to workers, augmenting human skills with computer powered data processing and insights. Artificial intelligence excels in data processing which, in turn, helps mitigate risks such as supply chain disruptions and cybersecurity attacks by finding them quickly and bringing them to the attention of human operators. This type of application is especially valuable as complex automation systems, used in everything from manufacturing to risk mitigation, are reaching their limits.

Using a more collaborative approach, AI powered industrial copilots offer simple, natural language interfaces with software, data and machines. For example, maintenance on a machine can be greatly accelerated if a built-in copilot allows a maintenance technician to simply ask the machine what the problem is and be presented with both the problem and a detailed set of instructions on how to fix it. Similarly, an industrial copilot can be thought of as an experienced colleague, well versed in vast quantities of industrial data that can be quickly applied to a given problem or used to help train new users and rapidly upskill a workforce.

As both design and manufacturing becomes more complex, the shortage of skilled labor will only become a greater issue. AI helps address this not only by helping new users learn tools and processes faster, but also by increasing the impact a single skilled worker has. An AI copilot can greatly reduce the amount of slow, menial tasks a user has to do, be that in design or production, increasing their efficiency and allowing them to focus on more important tasks.

In the future, AI agents will be able to handle even more complex tasks with a greater degree of autonomy, allowing users to shift to an orchestration role that dictates high-level ideas and tasks which a series of agents can work together to achieve. Agents can also work with less human oversight, allowing them to respond rapidly to changing conditions on the shop floor, improving efficiency, resiliency and flexibility in manufacturing without sacrificing on quality.

Artificial intelligence has a lot to offer through its adoption in industry but, beyond the data requirements, the driving force must be cooperation. Companies big and small with wide-ranging expertise and specialized knowledge must pool their resources, as Siemens and Nvidia have, to bring powerful, industrial-grade AI solutions where they can have the greatest impact.

To learn more, check out this podcast.

Siemens Digital Industries Software helps organizations of all sizes digitally transform using software, hardware and services from the Siemens Xcelerator business platform. Siemens’ software and the comprehensive digital twin enable companies to optimize their design, engineering and manufacturing processes to turn today’s ideas into the sustainable products of the future. From chips to entire systems, from product to process, across all industries. Siemens Digital Industries Software – Accelerating transformation.