Get ahead during the AI revolution

The AI revolution is accelerating. Seeing the impressive gains businesses both big and small have seen from leveraging AI-powered solutions. More and more companies are ramping up efforts to integrate AI into their everyday processes to keep pace with competitors and partners. While AI integration may seem intimidating at first glance, technologies such as the digital twin and AI agents ease the transition to an AI-driven automation.

In the fourth episode of industrial machinery and AI series in Siemens’ Digital Transformation podcast, the existing gaps in digital maturity among manufacturers was discussed. Host Chris Pennington, global industry marketing leader for industrial machinery, along with Rahul Garg, Vice President for industrial machinery vertical software strategy, spoke with Ralph Wagner, Senior Vice President of data-driven Manufacturing on the role of AI and digital transformation in industrial machinery. Their conversation focused on the benefits of the executable digital twin (xDT) and Copilot integration to streamline AI adoption.

Easing integration through simulation

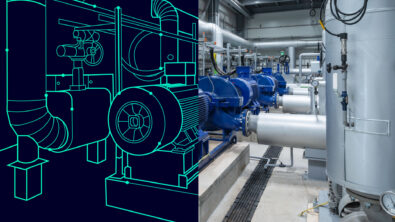

Simulation technology comes with the added benefit of being flexible and scalable. In many cases, virtual models can be large and computationally expensive, necessitating significant server infrastructure to run. The executable digital twin, or xDT, emphasizes speed and portability to bring the power of the digital twin to the shop floor.

Utilizing AI-driven reduced order models (ROMs), the xDT offers accurate inferences using far less computing power. Building off of the comprehensive digital twin, it leverages ROMs to simplify parts of a complex system by using existing data to train highly accurate AI models. Real-time xDT simulations enable manufacturers to:

- Quickly modify machines on the shop floor

- Optimize future machines and production systems

- Detect mechanical anomalies for preventative maintenance needs and better downtime scheduling

As well, many OEMs have made good use of the xDT in the design phase. Heller, a company that manufactures high-end milling machines, leveraged the xDT to monitor their product’s spindle motions. Due to the xDT’s highly accurate simulation capabilities, Heller could change the way the spindle moved to guarantee their customers would get an optimized product.

Unlocking data with Copilot

LLMs have also significantly accelerated AI integration on the shop floor by transforming how operators, engineers, and systems interact with industrial data. To cater to the needs of machine builders, Siemens developed the Production Copilot. Production Copilot enables operators to interact with shop floor data using natural language, helping them make the most of their data.

But our efforts to democratize AI don’t end there. Siemens is working with customers to develop an industrial foundational model, a more specialized LLM trained on industrial data. The industrial foundational model will fill in the gaps that many LLMs have when parsing manufacturing data, being able to understand engineering concepts, 3D geometry, time series data, and PLC code. Additionally, Siemens announced the launch of Copilot Studio for next September. Copilot Studio will empower customers to build custom AI agents and skills for tailored AI interactions.

Getting ahead is easy

With AI solutions becoming more advanced by the day, companies are reaping the benefits of starting their digital transformation journeys. And integrating AI is now easier than ever—and it all starts with data.

The digital twin and Copilot help unlock data on the shop floor, enabling operators to accurately analyze and monitor their data while leveraging it to improve operational efficiency and product optimization. LLMs are expected to become even more of a boon for manufacturers as Siemens continues to develop models that better understand engineering language and facilitate the creation of custom AI tools.

To learn more about the future capabilities of AI and how to jumpstart your digital transformation journey to keep pace with the competition, tune in to our Digital Transformation podcast.

Siemens Digital Industries Software helps organizations of all sizes digitally transform using software, hardware and services from the Siemens Xcelerator business platform. Siemens’ software and the comprehensive digital twin enable companies to optimize their design, engineering and manufacturing processes to turn today’s ideas into the sustainable products of the future. From chips to entire systems, from product to process, across all industries. Siemens Digital Industries Software – Accelerating transformation.