The role of the digital twin in software-defined heavy equipment

Software-defined products are becoming more prevalent in the heavy equipment industry. As demands for increased efficiency in processes such as food production and resource extraction grow, the machines that drive these processes often need to work longer hours in remote, sometimes hazardous, environments. Software and electronics boost such machines with qualities such as new functions, easily upgradable systems, and—in some scenarios—autonomy.

Despite these benefits, however, software-defined products had new layers of complexity to an already complex industry, adding even more requirements and considerations that come with their own challenges. As any company working in heavy equipment knows, failure to meet those challenges can be costly and even potentially dangerous. It is imperative then to find solutions to them as early in the product lifecycle as possible, which can be enabled by the comprehensive digital twin.

The complexity of software and electronics

The benefits of software-defined products for the heavy equipment industry are plentiful. Introducing software and electronics into systems that were traditionally mechanical opens new ways to enhance machine capabilities and increase the comfort of operators. Additionally, upgrades to machine systems can be pushed out very quickly through software updates. Not only is this less expensive than buying entirely new equipment, but it also helps keep equipment in the field longer without having to be taken away for upgrades, enabling machines to do more within the same amount of time.

As mentioned earlier, though, software and electronics come with their own complexities to their machines. They impose a multitude of interactions in machine systems that must be accounted for, which raise the risk of new, unforeseen errors that may arise. Software updates also carry their own risks if they are not properly validated. While such an issue might sound just inconvenient, in an industry such as heavy machinery, the consequences of a bad update can result in costly damages, loss in reputation, and threats to safety.

These complexities add to the already existing complexities of heavy equipment, which are usually highly customized to operate in unique environments with their own particular working conditions.

Keeping equipment reliable with the digital twin

To manage all this complexity while releasing software-defined products in a timely manner, heavy equipment companies will benefit from identifying system requirements as soon as possible and making them transparent across the product lifecycle.

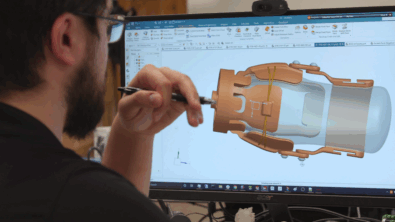

The comprehensive digital twin is just the technology for that purpose. As the virtual representation of a product throughout its lifecycle, the comprehensive digital twin ensures end-to-end data connectivity between all stakeholders in a product’s lifecycle, across all aspects of design, development, and operation.

One way it accomplishes this is through the utilization of simulation. Machine systems can be simulated virtually to identify errors and remove them before physical construction ever exists, as well as optimize those systems to withstand the conditions of the environments they operate in. By simulating first, companies can accelerate development cycles while reducing costs that would other be spent on testing or repairs down the line.

Simulation does not just apply to physical systems, but also software. With the right emulation tools, software updates can be simulated to see how they would interact with hardware, providing real-world context that can help validate updates before their sent out, reducing the risk of errors and increasing operational safety.

The comprehensive digital twin can give heavy equipment companies the early insights necessary to get their software-defined products into operation right the first time. As demonstrated by software updates, however, the digital twin’s benefits extend beyond the design and development of such products. By incorporating data from operation and elsewhere in the product lifecycle, the comprehensive digital twin enables continuous optimization of heavy equipment long after they hit the ground, ensuring quality and efficiency for years to come.

To learn more about how the comprehensive digital twin and other digital tools benefit the heavy equipment industry, check out this article from Hendrik Lange, Director of the Heavy Equipment Industry for Siemens Digital Industries Software.

Siemens Digital Industries Software helps organizations of all sizes digitally transform using software, hardware and services from the Siemens Xcelerator business platform. Siemens’ software and the comprehensive digital twin enable companies to optimize their design, engineering and manufacturing processes to turn today’s ideas into the sustainable products of the future. From chips to entire systems, from product to process, across all industries. Siemens Digital Industries Software – Accelerating transformation.