Embracing multi-disciplinary design for the future

In today’s rapidly evolving industrial landscape, machine engineering companies face unprecedented challenges and opportunities. The demand for smarter, more flexible, and highly customized machinery is reshaping the way machines are designed, produced, and commissioned. Siemens’ approach to advanced machinery engineering offers a transformative solution through the power of the digital twin and digital thread.

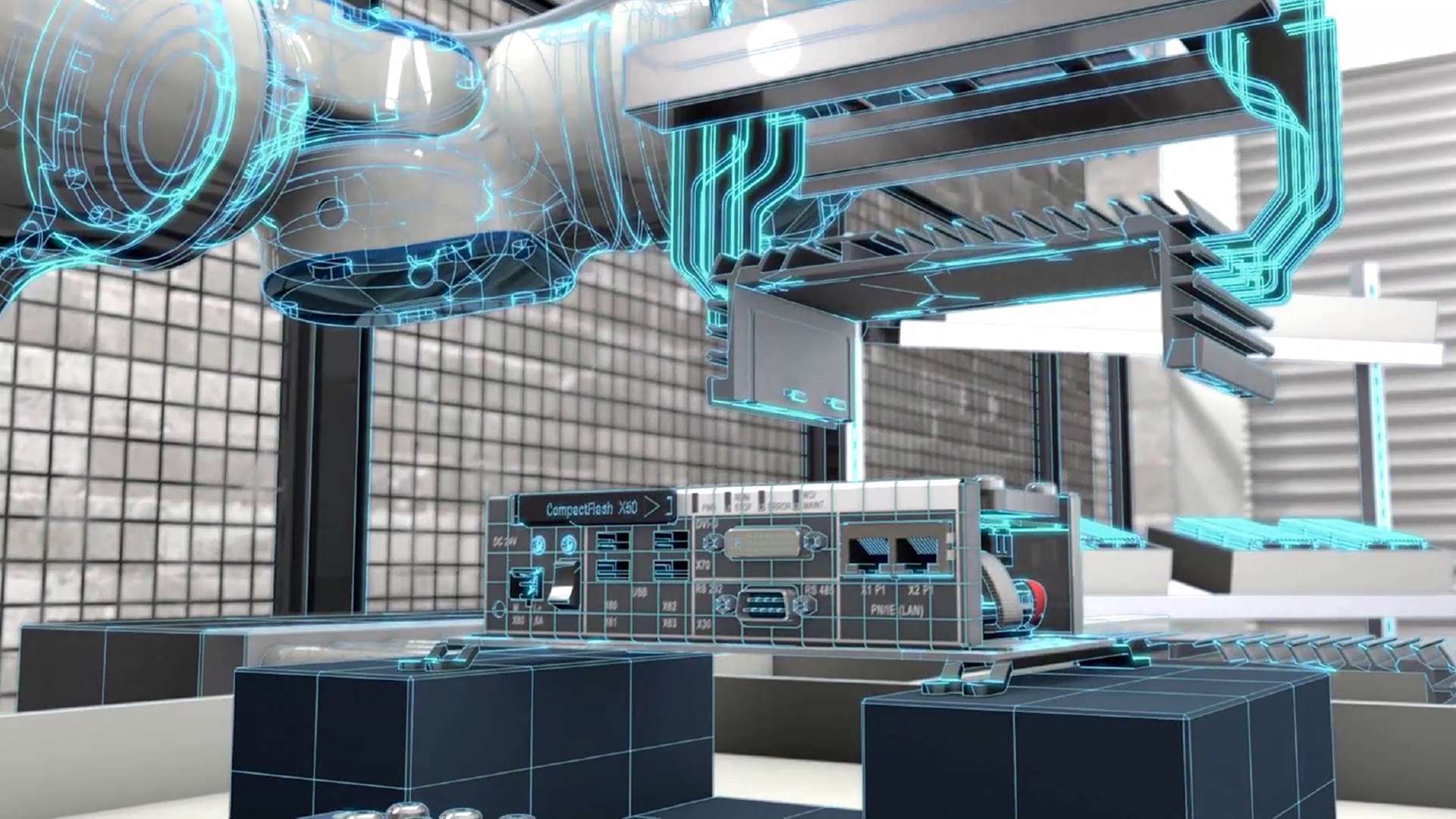

At the heart of Siemens’ strategy is the digital twin—a virtual representation of a machine that enables engineers to design, simulate, and test before physical production begins. This approach not only accelerates development but also ensures that machines meet technical, customer, and regulatory requirements from the outset.

Industry trends

Several global trends are influencing the machinery market: consumer-driven customization. Customers now expect equipment to be tailored to their specific needs. Flexibility and adaptability are paramount as the world becomes more interconnected and manufacturers seek to address the needs of their consumers all across the globe.

Additionally, the rise of the Internet of Things (IoT) is pushing for machines that are intelligently connected and capable of real-time data exchange. Many organizations have begun their digital transformation journeys, aspiring to actualize smart factories that can quickly and efficiently respond to supply chain changes and emerging consumer trends. Interconnected machines can also enable and facilitate predictive maintenance, quality control, and process optimization. Companies that are further along in their digitalization process have embraced automation. Through combining machine learning, software, and automation tools, manufacturers have found ways to streamline operations and enhance productivity.

And finally, regulatory complexity has been driving many manufacturers to pay special attention to their design and engineering processes. Increasing regulations demand more robust and compliant engineering processes. Global Competition: Pressure from low-cost providers is intensifying, necessitating innovation and efficiency.

Benefits of multi-disciplinary design

To stay competitive, companies must integrate mechanical, electrical, and software engineering disciplines. Siemens’ solution enables:

- 50% faster time to production

- 25% shorter commissioning phases

- Reduced costs by eliminating CAD system dependencies

- Improved collaboration with suppliers

- Enhanced data protection and seamless data management across the digital thread

The future is connected

By 2025, over 24 billion connected devices are expected to be in use globally. This connectivity is not just a trend—it’s a necessity. Siemens’ platform supports this shift by enabling virtual commissioning, real-time collaboration, and secure data exchange. To thrive in a complex and dynamic market, machine engineering companies must embrace digital transformation. Siemens’ provides the tools and strategies needed to build tomorrow’s machines today—faster, smarter, and more efficiently.

Siemens Digital Industries Software helps organizations of all sizes digitally transform using software, hardware and services from the Siemens Xcelerator business platform. Siemens’ software and the comprehensive digital twin enable companies to optimize their design, engineering and manufacturing processes to turn today’s ideas into the sustainable products of the future. From chips to entire systems, from product to process, across all industries. Siemens Digital Industries Software – Accelerating transformation.