Shift-Left with the Digital Twin: A New Era of Software-Defined Products – Part 1

In the latest season of the Industry Forward Podcast, host Conor Peick and Siemens Vice President Dale Tutt kick off a compelling new series focused on the transformative concept of the shift-left, as enabled by comprehensive digital twin technology. This season promises to delve into the evolving landscape of software-defined products across industries such as automotive, aerospace, semiconductors, and more.

To launch the conversation, Conor and Dale are joined by two seasoned experts from Siemens Digital Industries Software: Doug Burcicki, Senior Director of Automotive and Heavy Equipment Industries, and Scot Morrison, Vice President of Shift Left Software Product Management in the Hardware Assisted Verification group at Siemens EDA. Together, they bring decades of experience in embedded software, system modeling, and lifecycle collaboration, offering a rich perspective on the challenges and opportunities presented by the shift toward software-centric product development.

The Shift-Left Paradigm

“Shifting left” refers to the practice of moving design, engineering, and testing activities earlier in the product development cycle. This approach enables faster innovation, earlier identification of issues, and more efficient collaboration across teams. As Dale explained, this shift is particularly relevant in the context of software-defined vehicles (SDVs), where software updates can continuously enhance vehicle functionality long after the initial sale.

Scot elaborated on his team’s focus within Siemens EDA, which centers on virtual platforms for system-on-chips (SoCs) and enabling system-level digital twins. His background in embedded software and real-time operating systems positions him well to understand the intricacies of virtual testing and verification. These capabilities are essential for accelerating development timelines and ensuring robust performance in increasingly complex systems.

In concert, Doug emphasized that software-defined products represent one of the most impactful trends in industry, and the automotive industry especially, today. Vehicles are no longer static machines; they are dynamic platforms capable of receiving updates and new features over time. Of course, this shift is not limited to automotive—it’s reshaping aerospace, heavy equipment, and consumer electronics as well.

Collaboration and Complexity

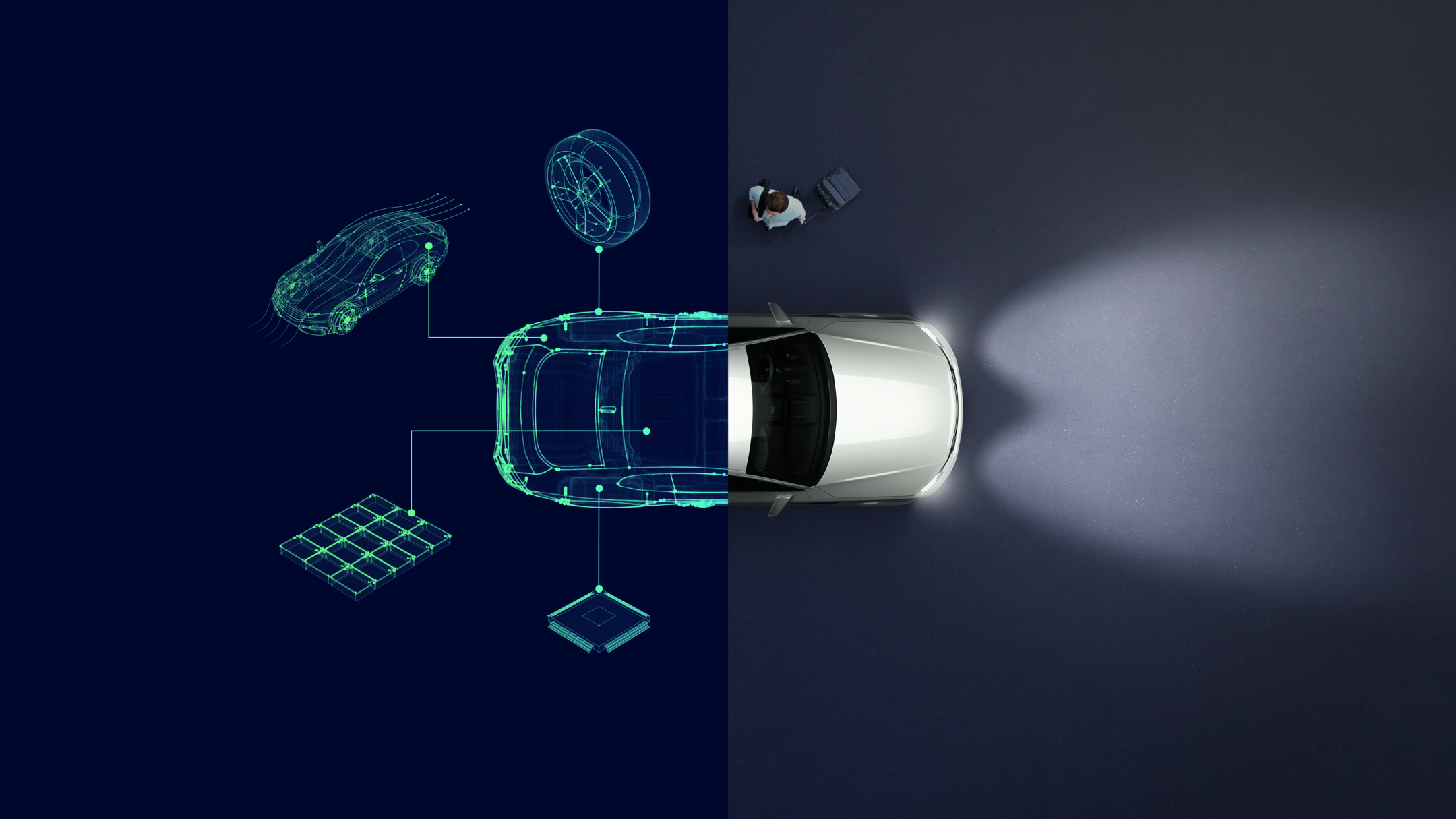

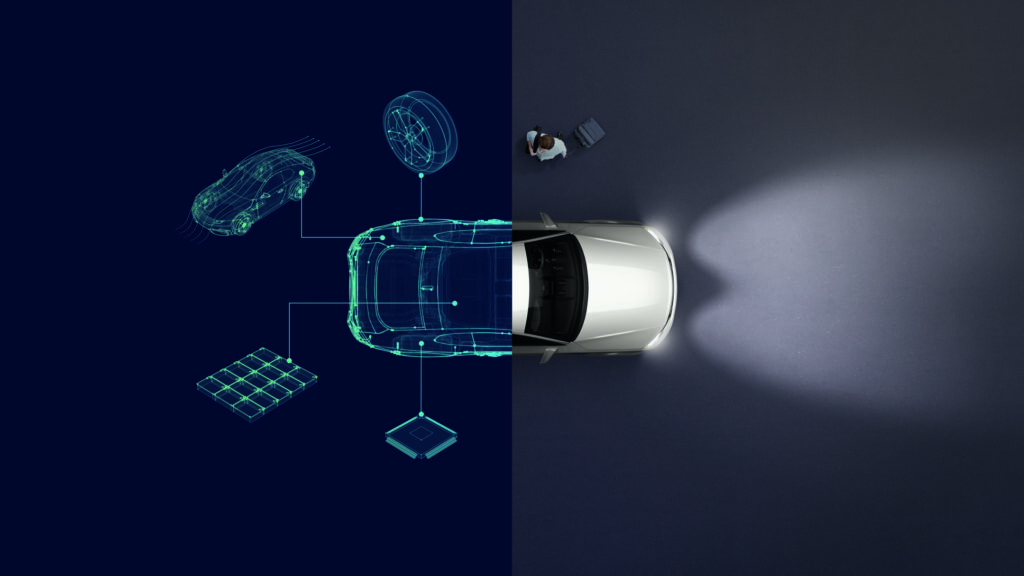

As industries embrace software-defined products, the complexity of development increases. Engineering teams must collaborate across disciplines, integrating hardware, software, and systems engineering in new ways. The digital twin—a virtual representation of a physical product—plays a crucial role in this process. It enables simulation, testing, and validation in a virtual environment, reducing reliance on physical prototypes and accelerating time to market.

Doug and Scot both highlighted the importance of fostering collaboration between traditionally siloed teams. By leveraging digital twin technology and shifting left, organizations can break down barriers and create more cohesive development workflows. This not only improves efficiency but also enhances product quality and innovation.

Navigating the Complexity of Software-Defined Systems

Continuing in the conversation, Scot underscored the magnitude of the shift facing today’s product developers. The transition to software-defined vehicles (and products more broadly) is not new, but the scale and complexity have reached unprecedented levels. With the proliferation of electronic control units (ECUs), increasingly sophisticated software workloads, and the integration of advanced technologies like AI, machine learning, and high-performance graphics, traditional development models are being stretched to their limits.

Scot pointed out that the classical, siloed development processes—where hardware and software were designed in sequence—are no longer viable. Instead, organizations must embrace hardware-software co-design, a concept long discussed but now essential. This means designing hardware platforms in tandem with the software workloads they are meant to support, optimizing for specific use cases such as AI reasoning or safety-critical applications.

Supporting Business Model Evolution

Doug added a critical layer to the discussion by highlighting the business motivations behind this technological evolution. For decades, OEMs (original equipment manufacturers) operated under a straightforward model: sell vehicles and generate profit per unit. But today, the focus is shifting toward lifecycle value—extending the revenue-generating potential of a product well beyond the point of sale.

This shift is powered by software. Features can now be added, updated, or enhanced over time through software updates, creating new revenue streams and improving customer satisfaction. However, enabling this model requires a fundamental rethinking of product architecture. Legacy systems must evolve, and in many cases, entirely new architectures must be developed from the ground up.

Doug noted that while no company has fully mastered this transition, many are on the journey. The competitive landscape is intense, with startups bringing agility and fresh thinking, while legacy OEMs must overcome deeply entrenched organizational structures and technical debt. Success in this environment demands not only technical innovation but also organizational transformation—new skill sets, new workflows, and new partnerships.

The Road Ahead: Integration and Collaboration

Both Scot and Doug emphasized that the path forward is not one that any company can walk alone. The complexity of modern systems, the pace of innovation, and the need for deep integration across disciplines mean that collaboration is key. Whether it’s between hardware and software teams, across departments, or with external partners, success in the era of software-defined products requires a unified, strategic approach.

As Doug said, “It’s a tough ask.” But it’s also what makes this moment so exciting. The convergence of digital twin technology, shifting business models, and the rise of intelligent, connected products is reshaping industries—and Siemens is at the forefront of helping companies navigate this transformation.

Siemens Digital Industries Software helps organizations of all sizes digitally transform using software, hardware and services from the Siemens Xcelerator business platform. Siemens’ software and the comprehensive digital twin enable companies to optimize their design, engineering and manufacturing processes to turn today’s ideas into the sustainable products of the future. From chips to entire systems, from product to process, across all industries. Siemens Digital Industries Software – Accelerating transformation.