Expanding AAM Range with Better Batteries Part One – Summary

At this point in time, batteries look to be the future power source for advanced air mobility (AAM). Many AAM companies, though certainly not all, are planning to use electric batteries to provide energy for their aircraft designs. With today’s battery technology, the predicted operating range of these designs is perfect for the urban transportation roles AAM is planned to provide. If the industry wishes to grow beyond that, however, this range must increase. Improving battery technology is key to making that happen.

In the latest episode of Talking Aerospace Today, Todd Tuthill, Vice President of Aerospace and Defense for Siemens Digital Industries Software, is joined by Puneet Sinha, Global Head of for the Battery Industry for Siemens, to explore how this can be achieved. They begin their discussion by highlighting why AAM companies should care about increasing range and the primary engineering concerns for designing batteries.

The need for larger AAM range

While the exact number differs across designs, Todd states the predicted range for many battery-powered AAM vehicles is predicted to be about 100 miles. This is a great range for the AAM industry to kick off with. For example, if one were to arrive at Los Angeles International Airport and take an air taxi from there, that air taxi could take them as far as San Deigo or Santa Barbara in a much shorter time while skipping all the ground traffic.

However, that 100 mile range would not be able to carry somebody from London or Paris, or Paris to Berlin. The AAM industry would be able to find its footing in transport within cities, but not yet between cities. Todd says if the industry wishes to grow and thrive, pushing beyond its limitations to achieve inter-city travel is the way to do so, and getting there will require better batteries to power its aircraft.

Engineering the perfect battery

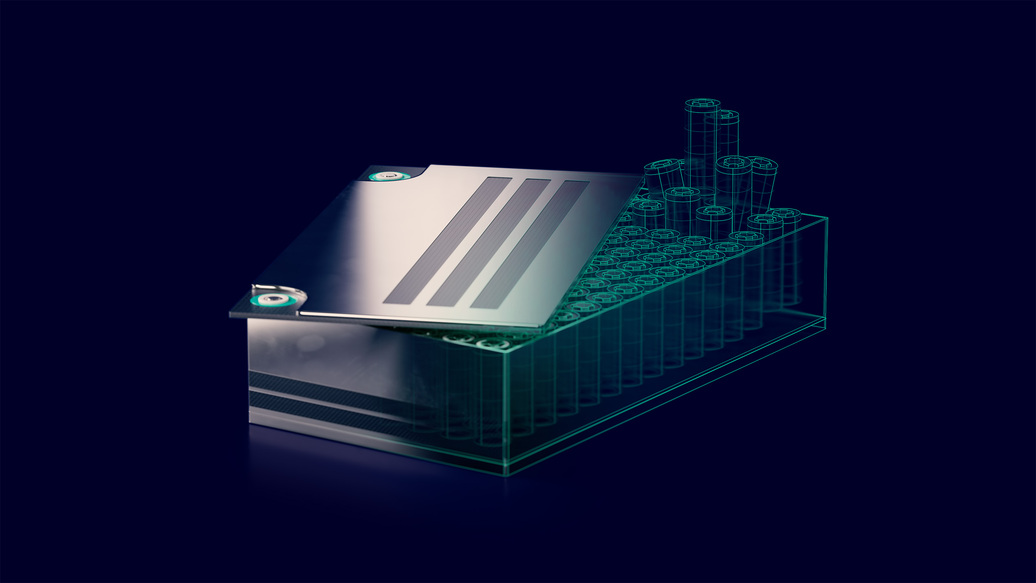

Puneet goes in depth on how improving existing battery technology involves increasing the flow and capacity of lithium within the battery. Within a battery, lithium flows between the battery’s electrodes, the anode and cathode, through a medium called an electrolyte, which is typically made of certain solvents and liquids. The speed of the lithium’s flow provides the power while the amount of lithium in the electrodes provides the energy. Exploring new chemistries to increase flow rate and lithium capacity can enable longer operating ranges for AAM vehicles.

Additionally, batteries have their own set of risks of failure and safety concerns to keep in mind as companies work to improve them. For example, a battery’s health and efficiency are impacted by the environmental temperature it operates in, with an optimal temperature between 10 and 31 degrees Celsius. A battery kept at high voltage can also accelerate its chemical reactions, decreasing its lifespan over time. These can significantly affect AAM operations, from flying in colder cities to how long air taxis charge in vertiports for.

Accounting for these risks is of especially crucial importance for AAM vehicles. As mentioned in previous podcast episodes on autonomous AAM, an autonomous car can simply pull over in most cases where there’s an issue, but an air taxi cannot. The same logic applies to battery power. Extra precautions and redundancies must be built into an air taxi so a potential midflight battery failure can be recovered from and keep people safe.

Building better batteries for AAM will have its challenges, but they will not be impossible to overcome. As Puneet states, battery energy density has already increased by three times in the past 15 years, all thanks to the innovations and chemistries developed for electrolyte designs. Where there is a will, there is a way, and with the right tools and knowledge, batteries of the future can enable AAM vehicles to go the extra mile and transform aerial transportation.

Stay tuned for the next episode of Talking Aerospace Today to learn how digital transformation can play a role in developing new batteries for AAM.

Siemens Digital Industries Software helps organizations of all sizes digitally transform using software, hardware and services from the Siemens Xcelerator business platform. Siemens’ software and the comprehensive digital twin enable companies to optimize their design, engineering and manufacturing processes to turn today’s ideas into the sustainable products of the future. From chips to entire systems, from product to process, across all industries. Siemens Digital Industries Software – Accelerating transformation.