Increasing AAM Range with Batter Batteries Part Two – Summary

As the advanced air mobility companies (AAM) turn to batteries to power their new aircraft, new complexities are introduced to the designs of their electrical systems. Engineers must balance increased weight with costs, aerodynamics, and more, all the while ensuring the aircraft can safely operate in populated areas. Managing all these competing factors, especially with siloed engineering methodologies, can increase time-to-market, but this can be circumvented thanks to digital transformation.

In the latest episode of Talking Aerospace Today, Todd Tuthill, Vice President of Aerospace and Defense for Siemens Digital Industries Software, is joined again by Puneet Sinha, Global Head for the Battery Industry for Siemens Digital Industries Software. They use this episode to dive deep into how tools such as the comprehensive digital twin can increase the safety of AAM vehicles and enable better batteries and electrical systems through connected, holistic engineering practices.

The complexities of battery-powered AAM

Safety was a significant point of focus in the first episode on batteries in AAM. The health of batteries can be impacts by the environmental temperatures they operate in, as well as the amount of voltage they are kept at, which can risk accelerating a battery’s chemical reactions and decrease its lifespan. The challenge of engineers is improving battery technology to increase AAM range while mitigating these risks.

Of course, a battery-powered electrical system is not isolated and has an impact on the other systems of an AAM vehicle. For example, one of the design considerations when using batteries for power is their heavy weight, which can impact how companies design an aircraft’s propulsion systems, such as how many rotor blades they want to include. Finding the right number to balance flight performance, costs and safety, however, can take a long time, and in an industry currently reliant on venture capital, the less time spent, the better.

Optimizing AAM and batteries with the digital twin

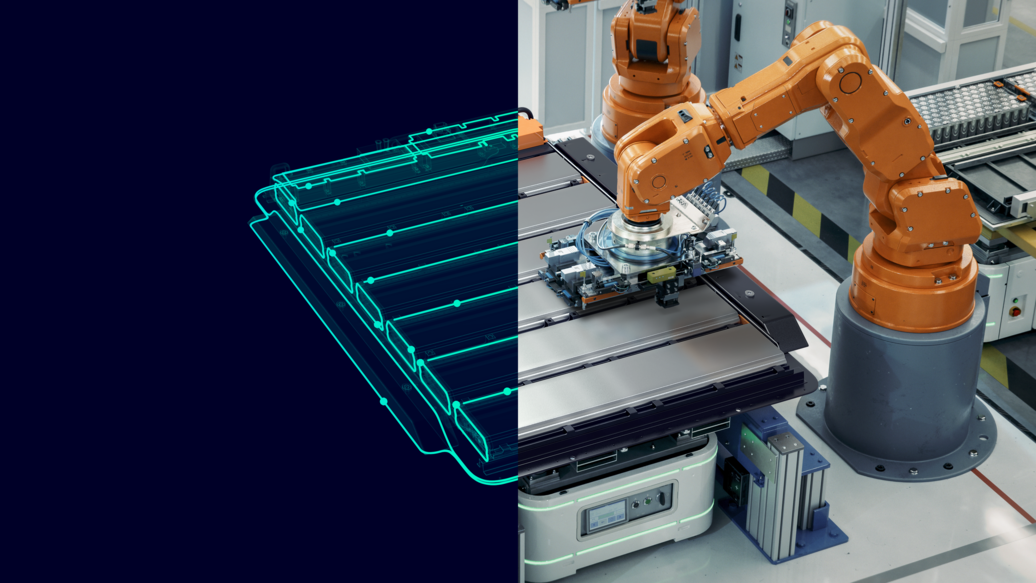

According to Todd, the comprehensive digital twin is the perfect tool to help companies find their ideal AAM designs while lessening their aircraft’s time-to-market. Instead of building multiple prototypes to test every little change they make to their aircraft, engineers can implement and test their changes virtually in the digital twin. As a virtual representation of an aircraft’s systems, engineers can analyze the trade-offs of each decision impacting flight distance, redundancy, optimal lift, and more. These insights can help optimize an air taxi before it is ever built physically, saving not only time, but also costs that would be spent on physical testing.

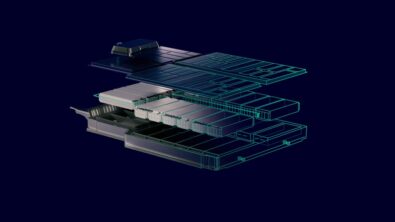

Puneet also states how the digital transformation and the digital twin are necessary when dealing with batteries themselves, as batteries should never be designed in a silo. Batteries are always in a system, incorporating the domains of chemistry, thermal, electrical, electronic, and software. Even the most microscopic change in material, whether it’s the material that holds lithium or simply the glue that holds things together, can have huge implications on the battery’s life, durability, and safety.

Digital transformation, through tools such as digital threads, helps the flow and traceability of data between these domains, enabling engineers to better incorporate all aspects of a battery during the design phase. Furthermore, the data from the battery can then be connected with the rest of an AAM vehicle’s systems, providing engineers the information to accommodate their design decisions for the battery and vice versa.

Batteries are a complex technology that can significantly impact an AAM vehicle, but digital transformation helps simplify that complexity into data companies can use to optimize their designs. By sorting out battery designs and optimizing the rest of the aircraft virtually, can get their aircraft built and certified much quicker, launching their fleets sooner and setting up the AAM sector for success from the beginning.

Keep listening to Talking Aerospace Today for more upcoming discussion on AAM and other topics in the A&D industry.

Siemens Digital Industries Software helps organizations of all sizes digitally transform using software, hardware and services from the Siemens Xcelerator business platform. Siemens’ software and the comprehensive digital twin enable companies to optimize their design, engineering and manufacturing processes to turn today’s ideas into the sustainable products of the future. From chips to entire systems, from product to process, across all industries. Siemens Digital Industries Software – Accelerating transformation.