The Mechanical Side of Generative Design Part Two – Summary – Talking Aerospace Today

Generative design has long been a goal for those in the mechanical engineering domain, originating from efforts to optimize topology and integrating more advanced functions later within new design tools. Now, as artificial intelligence (AI) becomes more involved in business and engineering processes, generative design is in a great position to tackle even more complex functions. Of course, people have many questions about such technology. What are the exact benefits of generative design? How do I know my data will be secure when using generative design with AI, especially in a data-sensitive industry like aerospace and defense (A&D)?

In the latest episode of Talking Aerospace Today, Todd Tuthill, Vice President of A&D for Siemens Digital Industries Software, and John O’Connor, Director of Aerospace Product and Market Strategy for Siemens Digital Industries Software, continue their conversation about generative design for the mechanical domain. Together, they explore the capabilities generative design has to offer today, describe how those capabilities can improve future engineering processes, and address concerns about data security.

The capabilities today…

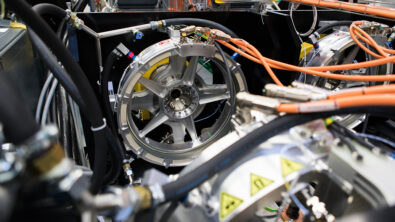

According to John, one of the best things about generative design tools today is their integration with other engineering tools, including traditional computer-aided design (CAD) tools. Artifacts made with generative design are often attuned to the pure physics of the desired constraints, so the integration of traditional CAD tools gives engineers and easier time to add additional details the generated design might have missed. This also gives more flexibility in creating a design more different manufacturing methods, whether it is subtractive manufacturing, additive manufacturing, or a combination of the two.

Another crucial integration generative design can include is with simulation tools. Having a good simulation tool that employs multiphysics solutions provides an environment where the generative algorithms—as well as integrated AI—employed can better make designs based on the desired constraints. By utilizing accurate simulations of structural, thermal, magnetic, etc. constraints, the generated design can be produced at a significantly higher quality.

…build tomorrow’s engineering

Delegating design to generative tools offers engineers and companies significant time-saving opportunities. The exact amount is somewhat of a moving target. After all, the tool could still be generating something that would take an incredibly long, difficult time for a human to design anyway. That said, if given a sufficient number of design cycles to perform their work, John suggests generative design tools could cut down the time it takes to design a new artifact by as much as 80 percent.

The implications of such a reduction in time spent are wide-reaching across the engineering process. Todd remarks how with that much time saved, engineers would now have more than enough time to dedicate themselves toward more high-level engineering, be more creative, and actually apply the knowledge they learned in education instead of being bogged down by trivial tasks. As discussed in previous episodes, this would multiply the impact these engineers would have in their work and help companies withstand the effects of worker shortages.

Securing data in generative design

As enticing as those benefits may sound, some companies, especially those in the A&D industry, may have concerns over access to their data with AI-enabled generative design. Aerospace programs are very proprietary, and those in the defense sector are often classified. According to Todd, some companies are understandably hesitant to give AI, or the software providers behind the AI, access to their proprietary or classified data in fear of security risks.

Fortunately, the AI used for generative design does not have to be as open as the types of AI seen in the news. As discussed on previous episodes, a generative design tool can be used to take data only from a company’s proprietary data lake, separate and apart from competitors and software providers. Some companies are even doing this now. This way they will still be able to reap generative design’s benefits while keeping their data secure.

The potential is soaring

Generative design for the mechanical domain today is the culmination of years of efforts automating and optimizing design tools to allow engineers to make new design artifacts like never before. Thanks to recent developments in AI, the potential for an even more robust form generative design has heightened significantly. It will still be some time before these tools will be able to take on truly complex, enormous designs, but as technology continues to develop, that horizon is drawing ever closer.

Stay tuned for the next episodes of Talking Aerospace Today about the final stage of digital transformation maturity, closed-loop optimization.

Siemens Digital Industries Software helps organizations of all sizes digitally transform using software, hardware and services from the Siemens Xcelerator business platform. Siemens’ software and the comprehensive digital twin enable companies to optimize their design, engineering and manufacturing processes to turn today’s ideas into the sustainable products of the future. From chips to entire systems, from product to process, across all industries. Siemens Digital Industries Software – Accelerating transformation.