Navigating battery electrification on The Battery Podcast

Battery is a rapidly growing industry, further boosted by governmental investment and the need to decarbonize our transportation sector. To talk about the shifts to business, technology, and experience Puneet and myself sat down with Dr. Cecile Pera from WeAutomotive Group. As an industry influencer with a diverse background in both automotive and electrification domains, she was the perfect pick for this discussion on shifting market dynamics and the innovation drivers surrounding electric vehicles (EVs).

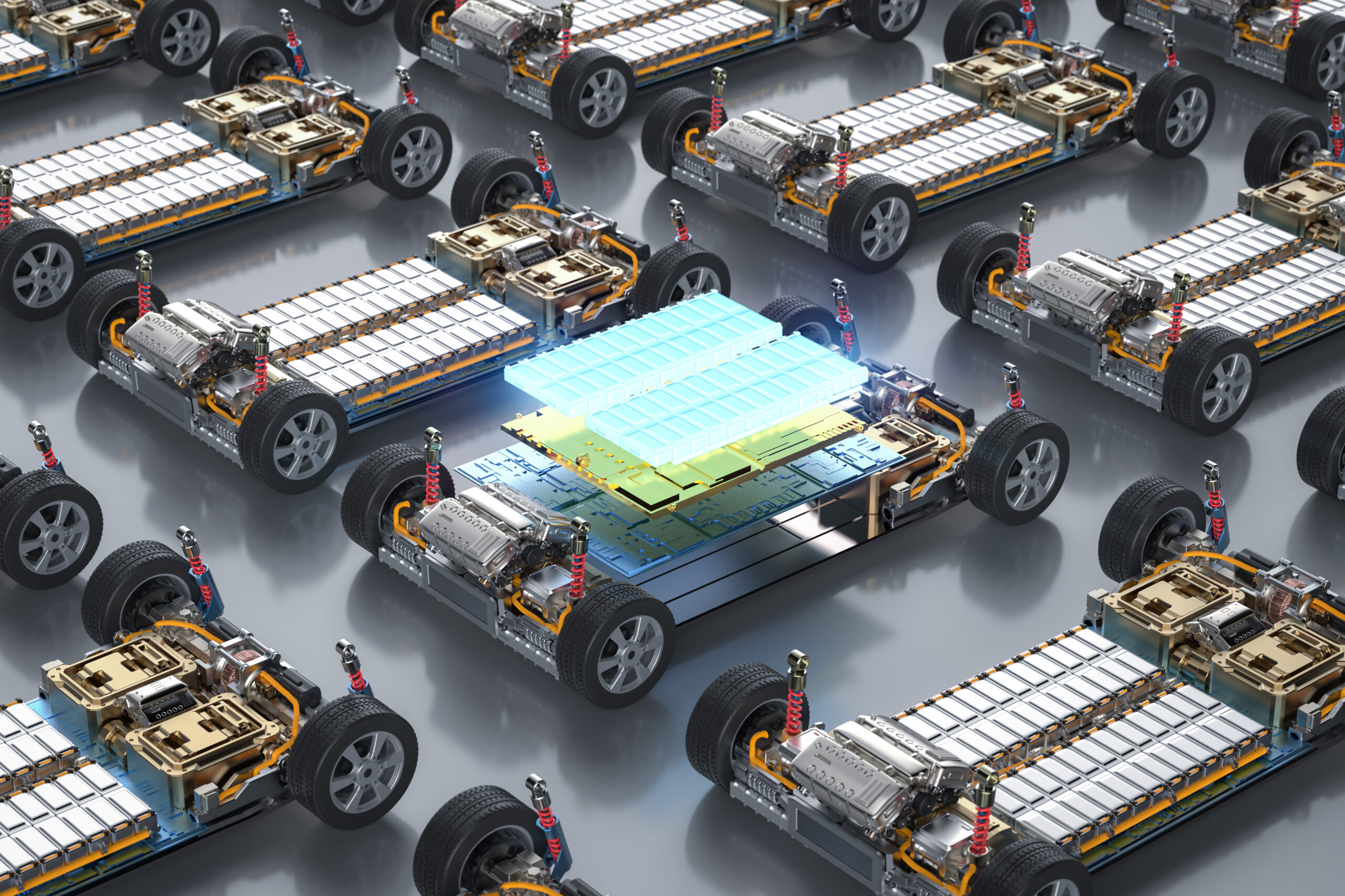

In this first half of our discussion, we cover some of the general architectures battery companies are deploying for production and use as well as some of the manufacturing challenges suppliers and OEMs are facing today.

From Dr. Pera’s perspective, “manufacturing works together with the technology you are trying to build, together in the pack design. What I mean is that sometimes it’s very difficult for people to understand that the best technology on one single problem is not necessarily the best technology to apply when you see the things as a system level. When I say the system level, I do not necessarily talk about just the battery pack, but the full electric vehicle, because something you are designing on a battery pack can have consequences on the vehicle itself.”

She went on to explain that “if you take gap filler or thermal interface material…between the module and the cooling plate” the goal is to increase the heat conductivity to improve cools of the cells and packs. The problem is that the paper solution is to increase the viscosity of the material to prevent loss of contact between the surfaces but doing so increases the probability of blockage in the extruder during manufacturing. A system view of this design and manufacturing decision prevents purely performance decisions from impacting manufacturability and vice-versa.

Later in the conversation we also broached the topic of testing and safety for battery systems as they become part of more and more vehicles on the road. Even as something as seemingly simple as a radio “would be thousands of different tests to be compatible with different regulations, different standards and so on.” Dr. Pera continued, “of course, battery being a very complex system gets also a lot of tests.” But the difficulty is not necessarily the number of tests, but the variation depending on the region for the vehicles. They are “slightly different in Korea, in Europe, in U.S., in China, and in some sense everyone tried to develop its own system.” Expanding on her insight, it is easy to see why digitalization is so important to maintaining regulatory compliance for these manufacturers – good testing procedures could streamline some of the overlap between regulation sets.

And because these are such highly integrated products, we returned again to the importance of a system level understanding of the product. Thermal runaway is a serious danger in EVs and the testing needs to be undertaken at each level of the battery – cell, module, pack, and full vehicle – to really know how to mitigate the risks.

But these are only the major points of the discussion. For more information you will want to listen to the full episode available above. And checking out The Battery Podcast from Siemens Digital Industries you can also listen to the second half of our discussion talking about the technology innovations seen today in the EV market. Or if you are more interested in the production side of the battery industry, check out episode two where Marc Deyda talks with industry experts from the Battery Show Stuttgart. And as always you can learn more on our website at siemens.com/battery.

Siemens Digital Industries (DI) is a leading innovator in automation and digitalization. In close cooperation with its partners and customers, DI is the driving force for the digital transformation in the process and manufacturing industries. With its Digital Enterprise portfolio, Siemens provides companies of all sizes with all the necessary products, along with consistent solutions and services for the integration and digitalization of the entire value chain. Optimized for the specific requirements of individual industries, this unique portfolio enables customers to enhance their productivity and flexibility. DI continuously extends its portfolio to include innovations and the integration of future-oriented technologies. Siemens Digital Industries, with its headquarters in Nuremberg, has a workforce of around 72,000 people worldwide.

For more information on Siemens Digital Industries products and services, follow us on LinkedIn, Facebook, Twitter, and YouTube.