Understanding engineering intent with AI

I recently had the opportunity to sit down with Richard Barnett, Chief Marketing Officer for Supplyframe, and discuss the ways they’re using AI to build a smarter supply chain across the electronics industry. By leveraging the huge quantities of data available to them, Supplyframe is attempting to gauge the engineering intent of their buyers – determining what chips or components will be crucial in next years smartphone or car before they hit the market. Richard discusses all this and more in a recent podcast, available here, or keep reading for some of the highlights from our conversation.

First, a quick overview of what Supplyframe does. Supplyframe’s offers a unique industry ecosystem, and pioneering Design-to-Source Intelligence (DSI) Solutions which transform how people and businesses design, source, market, and sell products across the global electronics value chain. Leveraging billions of continuous signals of design intent, demand, supply, and risk factors, Supplyframe’s DSI Platform is the world’s richest intelligence resource for the electronics industry with over 10 million engineers engaging with the platform worldwide.

Determining semiconductor buyer intent

Gauging buyer intent is one of the cornerstones of modern ecommerce platforms with major retailors sinking vast quantities of time and money into doing just that. This is fairly mature when it comes to understanding consumer buying intent. For example, if someone buys hotdogs, they might also want to buy hotdog buns. However, suggesting possible additional electronics components an engineer might need based on current searches is a far more difficult task.

A simple integrated circuit, or IC, might have many applications ranging from the complex, such as the aforementioned car or smartphone, to the mundane, like the humble toaster. This makes the intent behind researching or buying an IC very difficult to gauge. For example, if the IC is used in a toaster perhaps it is one of the only electronic components used. Whereas the same component included in a new smartphone could signal a huge spike in demand for numerous other ancillary components as well. A company able to understand when interest in a particular part will trigger a swath of other orders and stock inventory accordingly stands to land in a far more favorable position then one which cannot.

AI analysis leads to better buying decision

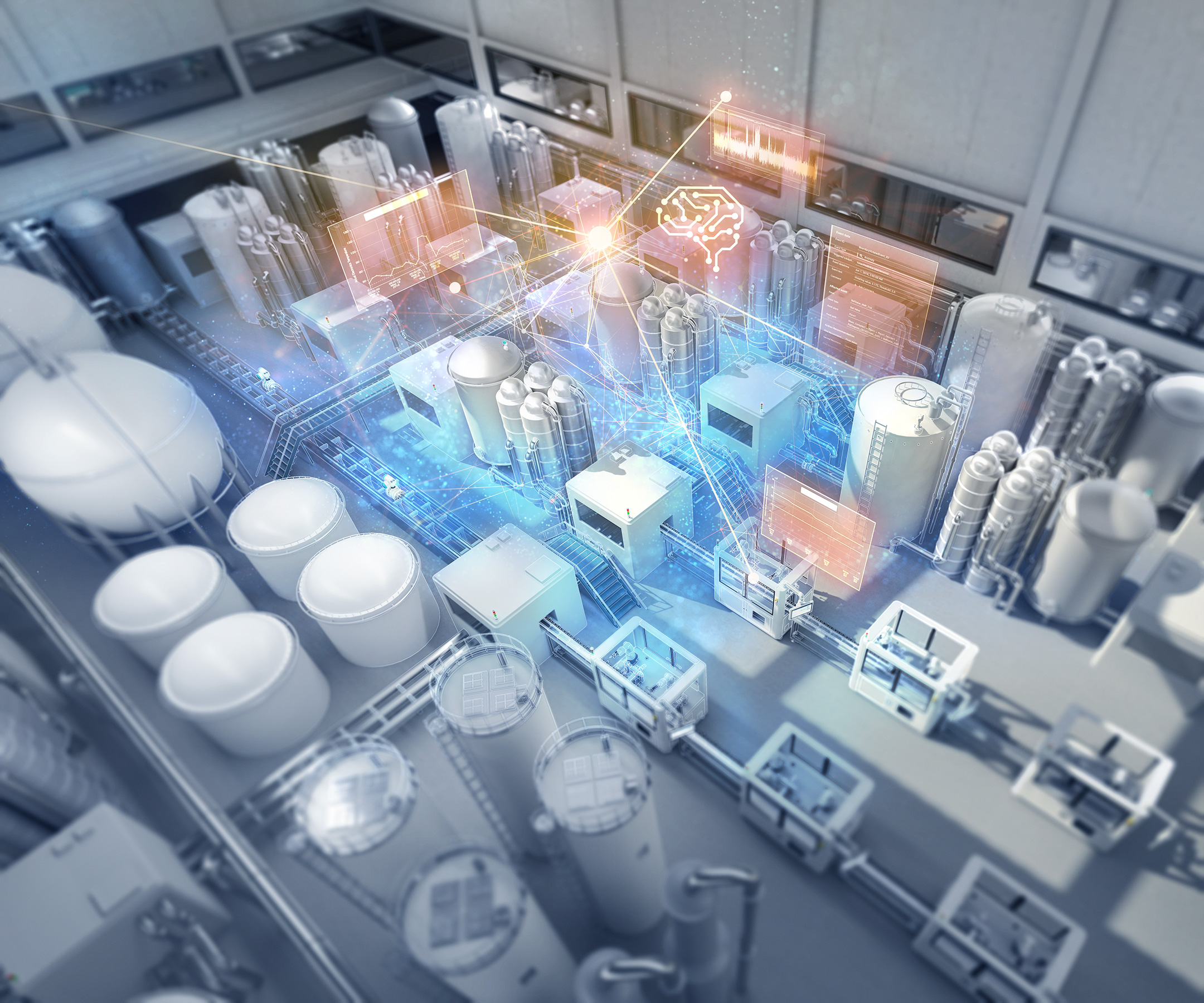

It is exactly this type of intent, Richard explains, which Supplyframe seeks to understand using AI. By looking at the network of data and “digital exhaust” created by their 10 to 12 million daily users Supplyframe’s AI model searches for patterns across the entire breadth of the electronics value chain. To generate insights these AI models don’t just look at what engineers are searching for but a wider selection of data as well. On one end, knowing what parts are being imported into CAD environments shows clear buying intent while on the other end accounting for conditions outside of the direct supply chain can help predict major part shortages and long lead times.

When considering the price and availability of a particular part it’s important to consider more than just who’s buying it and for what purpose. Factors such as raw material availability or natural disasters disrupting logistics systems also play an important role. Seemingly unrelated events can have a huge impact on one another and Supplyframe is using AI to analyze the vast quantities of data available from numerous, disparate sources in order to understand this web of connections.

Artificial intelligence offers many capabilities across a wide range of applications but one of the core pillars it was built on is the handling and analysis of large data sets, a field in which it remains nearly unparalleled even to this day. Understanding something as vast and complex as the interconnected web of suppliers, consumers, and producers of ICs and other components as well as the impact changes small and large, internal and external may have on it is a daunting task, but one well suited to the particular prowess of AI. Picking out patterns from this inscrutable web, while difficult, offers rich rewards to those who undertake the task which is why Supplyframe offers their AI-driven insights as a service, helping its customers better understand where the market is and where it’s going.

Siemens Digital Industries Software helps organizations of all sizes digitally transform using software, hardware and services from the Siemens Xcelerator business platform. Siemens’ software and the comprehensive digital twin enable companies to optimize their design, engineering and manufacturing processes to turn today’s ideas into the sustainable products of the future. From chips to entire systems, from product to process, across all industries. Siemens Digital Industries Software – Accelerating transformation.